Connecting tool for clamping optical lens

An optical lens and tooling technology, applied in clamping, positioning devices, manufacturing tools, etc., can solve the problems of low production efficiency, increased time cost, wear and tear of machine tool spindle connecting threads, etc., to improve production efficiency, stabilize the floating process, reduce time cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

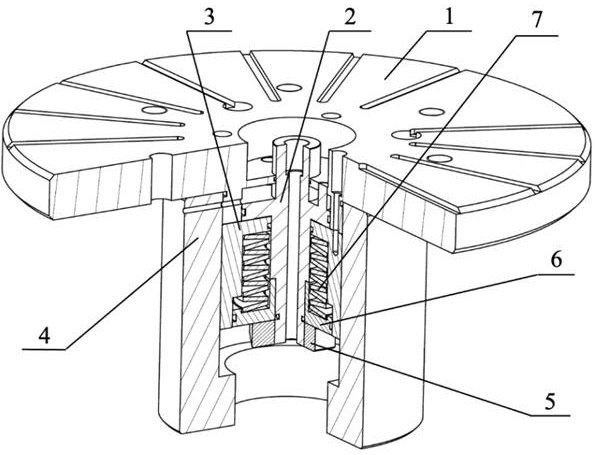

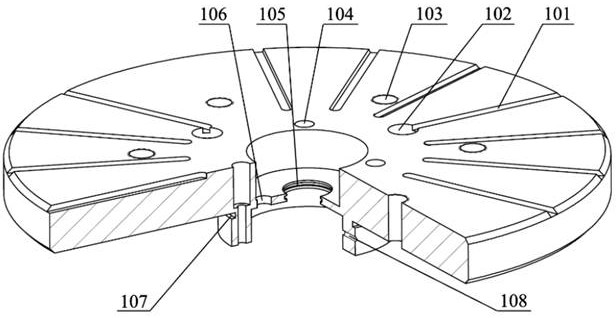

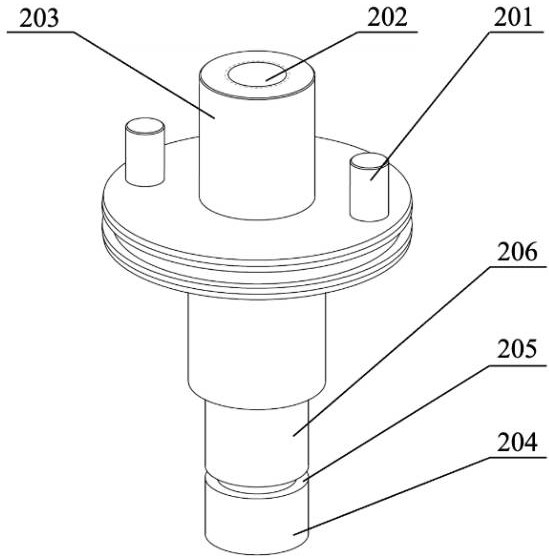

[0047] Such as Figure 1~6 As shown, this embodiment discloses a connection tool for optical lens clamping. The connection tool includes a flange 1 for connecting the fixture, a cylinder 4 arranged at the bottom of the flange, and a cylinder 4 arranged in sequence from top to bottom. 4 The inner hollow floating shaft 2, spring sleeve 3, disc spring 7, spring push cover 6 and locking nut 5, the cylinder 4, spring sleeve 3 are connected with the flange 1 by bolts.

[0048] In this embodiment, the cylinder 4 is provided with a main shaft connecting thread 403, and the main shaft connecting thread 403 on the cylinder 4 is connected with the main shaft, and the main shaft thread 403 is wrapped with raw tape to prevent air leakage.

[0049] In this embodiment, the center of the flange 1 is provided with a groove, and the center of the groove is provided with a through hole for the top of the hollow floating shaft 2 to pass through. The flange 1 around the through hole is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com