Fracturing pump connecting rod machining datum marking method

A technology for machining datums and fracturing pumps, which is applied in the field of datum scribing for connecting rods of fracturing pumps. Scrap rate, the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The application will be described in detail below in conjunction with the accompanying drawings.

[0017] A fracturing pump connecting rod processing datum marking method, which includes the following steps:

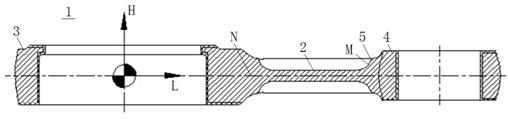

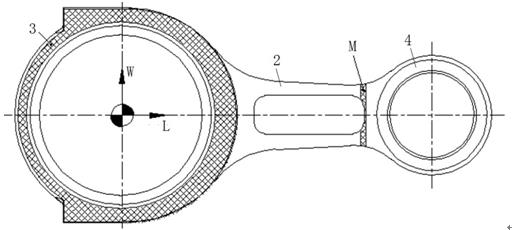

[0018] S1, placing the connecting rod body 1 on a plane, the connecting rod body 1 is an integrally formed steel casting, see figure 1 and figure 2 , the connecting rod body 1 includes a shaft 2 and a connecting rod big end 3 and a connecting rod small end 4 connected at both ends of the shaft, the transition section where the connecting rod small end 4 is connected to the shaft 2 is provided with a raised transition circle corner 5. Measure the first flatness of the plane where the shaft 2 is located. If the first flatness is 1 mm or less, proceed to the next step. If the first flatness is > 1 mm, add the surface of the shaft to ensure that the first flatness is 1 mm. and below.

[0019] S2, align the plane where the rod body 2 is located, and measure the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com