Finite element simulation method for multi-rack cold continuous rolling plate shape

A simulation method and cold tandem rolling technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as reduced calculation time steps, difficult accuracy of calculation results, and sudden increase in the number of strip units , to achieve the effect of avoiding distortion and distortion, continuous forecasting and analysis, and reducing the number of units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The implementation process of the present invention will be described in detail below with reference to specific analyzed embodiments, and model pictures of the embodiments are shown in the accompanying drawings. The embodiments described below with reference to the accompanying drawings are exemplary, only used to explain the present invention, and should not be construed as a limitation on the method of the present invention.

[0056] Table 1 and Table 2 list the roll size parameters and the rolling process parameters of steel grade 590DP in an actual production process of a cold rolling production line in a steel plant. According to the following parameters, the finite element analysis model of cold tandem rolled flat shape is established.

[0057] Table 1 Dimensions of rolls

[0058]

[0059] Table 2 590DP rolling process parameters

[0060]

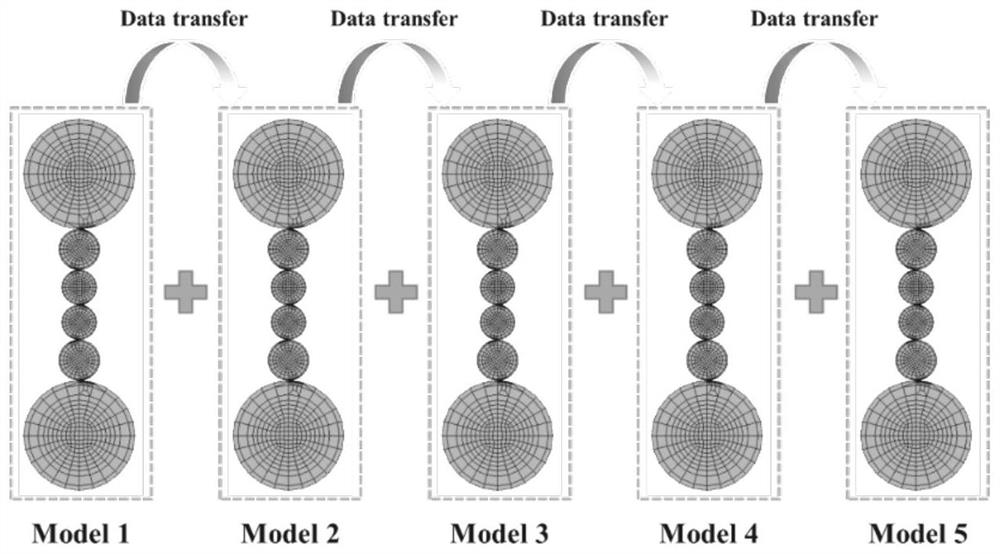

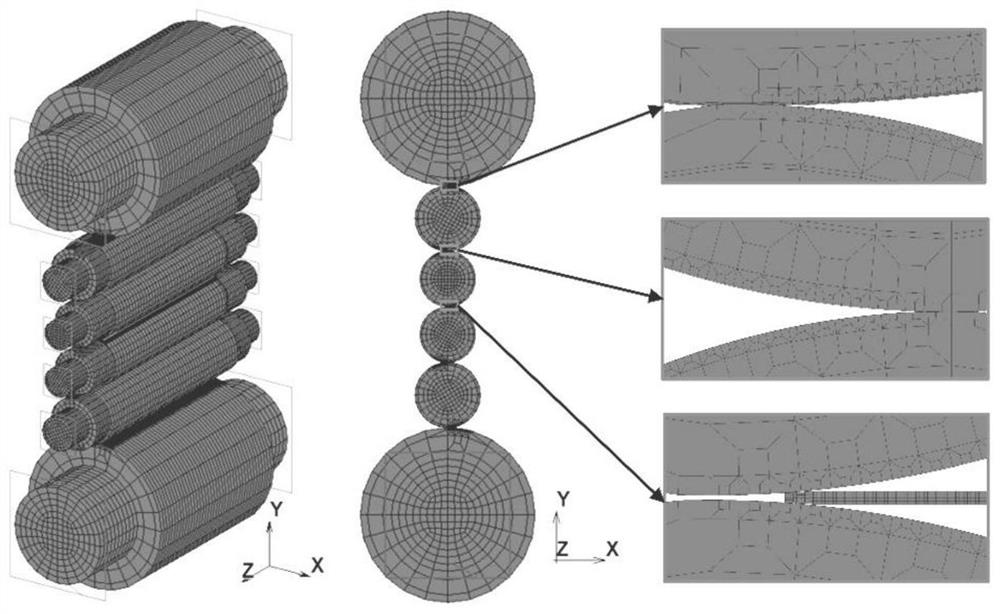

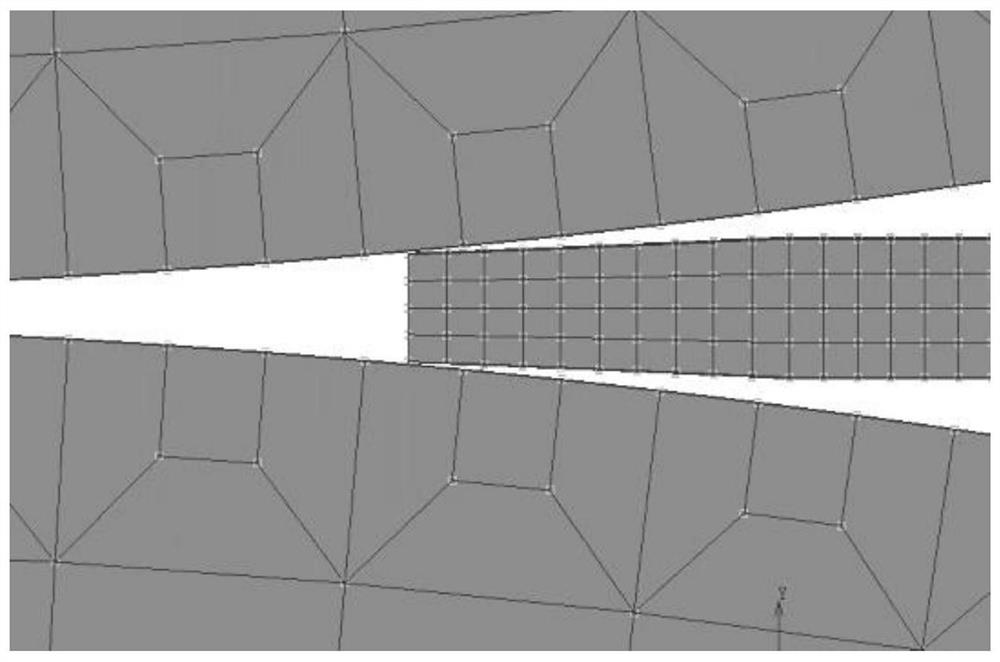

[0061] The modeling idea of the multi-stand cold rolling strip finite element simulation method of the present inv...

Embodiment 2

[0075] Using the roll size parameters (as shown in Table 1) and the rolling process parameters of steel grade DC01 (as shown in Table 4) in an actual production process of a cold tandem rolling production line of a steel plant to establish a cold tandem rolling finite element Analyze the model, and carry out the simulation calculation according to the above-mentioned multi-stand cold rolling strip finite element simulation method. Table 5 shows the comparison between the calculated rolling force and the measured rolling force of each stand of DC01. It can be seen that the calculated rolling force is basically consistent with the measured rolling force, and the relative error is within 5%, which once again verifies the accuracy of the method in calculating the rolling force.

[0076] Table 4 DC01 rolling process parameters

[0077]

[0078] Table 5 Comparison results of rolling force of each stand of DC01

[0079]

[0080] Figure 12 The calculated values of the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com