Positive liquid crystal composition and application thereof in liquid crystal display device

A technology of liquid crystal composition and positive liquid crystal, which is applied in the direction of liquid crystal materials, nonlinear optics, instruments, etc., can solve problems affecting the response time of liquid crystal composition, high rotational viscosity, etc., and achieve improved low temperature working effect, low rotational viscosity, Improve the effect of contrast and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] A liquid crystal composition provided in this embodiment comprises the following components:

[0125] (1) A compound of formula I-40 accounting for 4.5% of the total weight of the liquid crystal composition;

[0126] (2) Compounds of general formula II accounting for 59.5% of the total weight of the liquid crystal composition: 48.5% of formula II-12, 5% of formula II-15 and 6% of formula II-33;

[0127] (3) The compound of general formula III accounting for 29% of the total weight of the liquid crystal composition: 5% of formula III-16, 3% of formula III-115, 15% of formula III-116, 2% of formula III-117 and 4% of formula III-93;

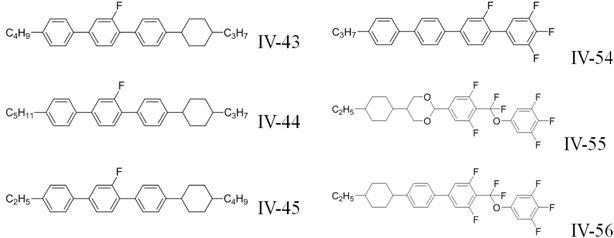

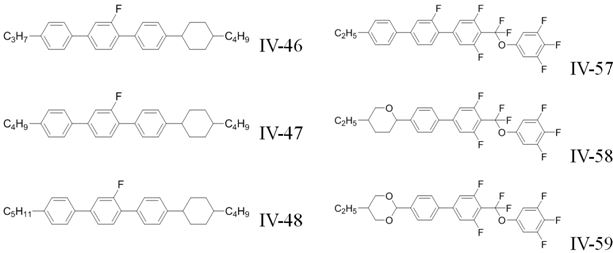

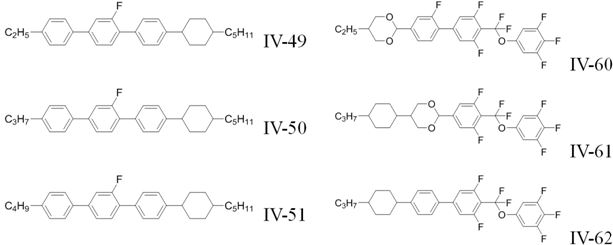

[0128] (4) The compound of general formula IV accounting for 7% of the total weight of the liquid crystal composition: respectively 1% of IV-53 and 6% of IV-63 compound.

Embodiment 2

[0130] A liquid crystal composition provided in this embodiment comprises the following components:

[0131] (1) The compound of general formula I accounting for 18.5% of the total weight of the liquid crystal composition: containing 7.5% of the compound of formula I-48 and 11% of the compound of formula I-40;

[0132] (2) Compounds of general formula II accounting for 49.5% of the total weight of the liquid crystal composition: 40% of formula II-12, 2% of formula II-15 and 7.5% of formula II-33;

[0133] (3) The compound of general formula III accounting for 31.5% of the total weight of the liquid crystal composition: 3% of formula III-93, 10% of formula III-112, 10.5% of formula III-113 and 8% of formula III-114 ;

[0134] (4) 0.5% of the compound of formula IV-54 based on the total weight of the liquid crystal composition.

Embodiment 3

[0136] A liquid crystal composition provided in this embodiment comprises the following components:

[0137] (1) a compound of formula I-68 accounting for 6% of the total weight of the liquid crystal composition;

[0138] (2) Compounds of general formula II accounting for 50% of the total weight of the liquid crystal composition: 34% of formula II-12, 6% of formula II-15 and 10% of formula II-33;

[0139] (3) Compounds of formula III accounting for 40.5% of the total weight of the liquid crystal composition: 2% of formula III-16, 4% of formula III-18, 6.5% of formula III-98, 10% of formula III-105, 7% of III-112 and 11% of formula III-113;

[0140] (4) 3.5% of the compound of general formula IV accounting for the total weight of the liquid crystal composition: respectively 3% of IV-64 and 0.5% of formula IV-53.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com