Local ion nitriding method for inner cavity of precipitation-hardening stainless steel annular part

A precipitation hardening, ring-shaped part technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve problems such as inability to meet the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

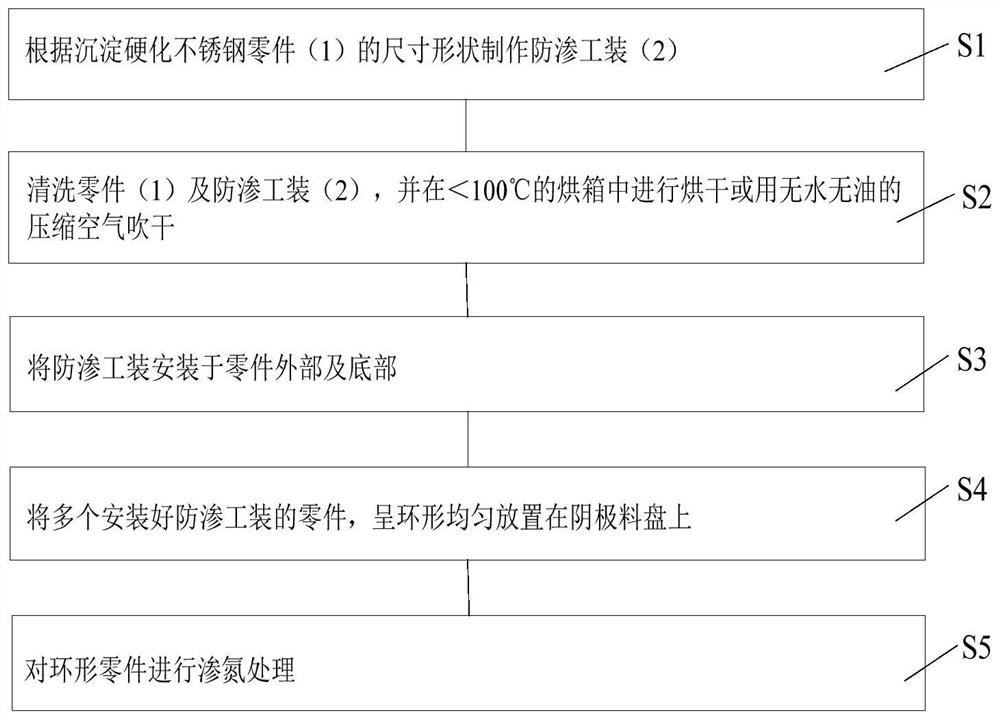

[0037] see Figure 1-4 , including the following steps:

[0038] Step S1, the detailed description is as follows:

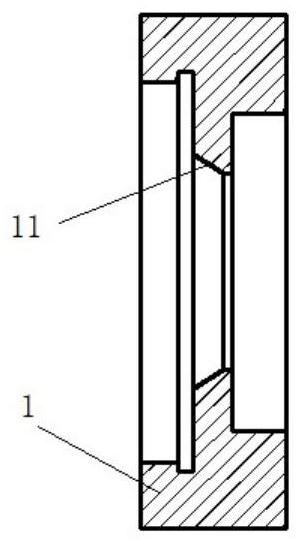

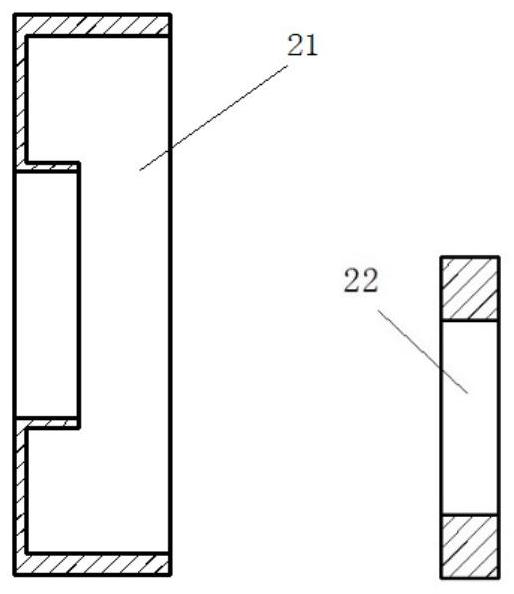

[0039] The anti-seepage frock (2) is manufactured according to the size and shape of the precipitation-hardened stainless steel ring part (1). The shape of the part is a ring structure; the inner cavity has a ring-shaped protruding step, and the surface to be nitrided is an inner circular surface (11) on the protruding step. The anti-seepage tooling (2) is composed of a component (21) and a component (22). The component (21) covers the upper surface of the part, and the middle through hole exposes a part of the surface of the inner cavity that needs nitriding, and covers the parts of the inner cavity that do not need to be nitrided; the component (22) It is placed under the inner cavity of the part, with a through hole in the middle, exposing the partial surface of the inner cavity that needs nitriding, and covering the inner cavity that does not need nitriding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com