Automatic reset buffer door hinge

An automatic reset and door hinge technology, applied in door/window accessories, switches with brakes, wing parts, etc. The effect of oil backflow, increasing bearing weight and avoiding stuck state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

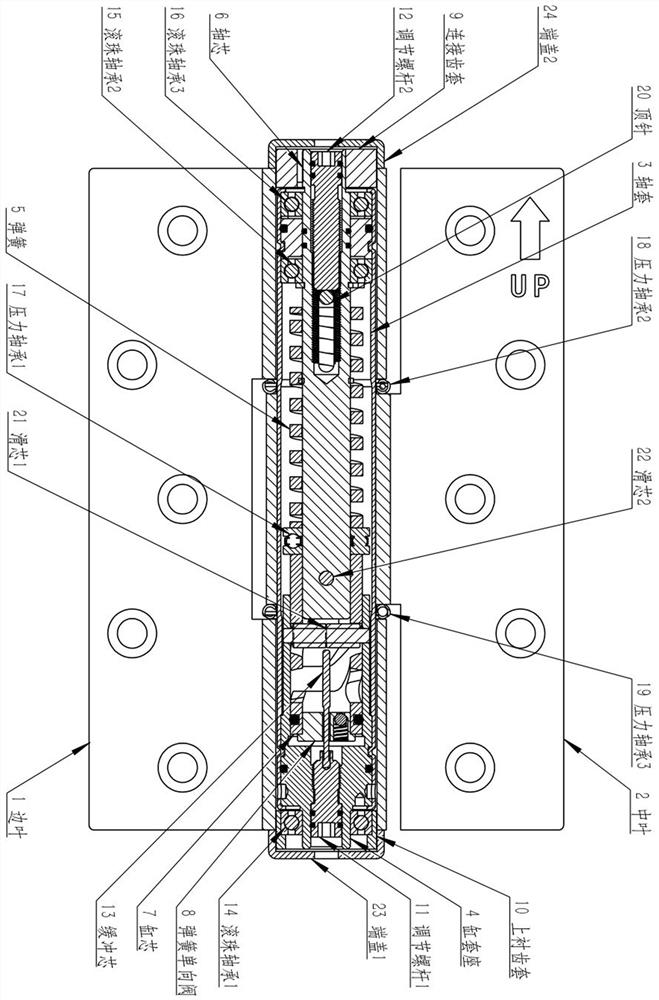

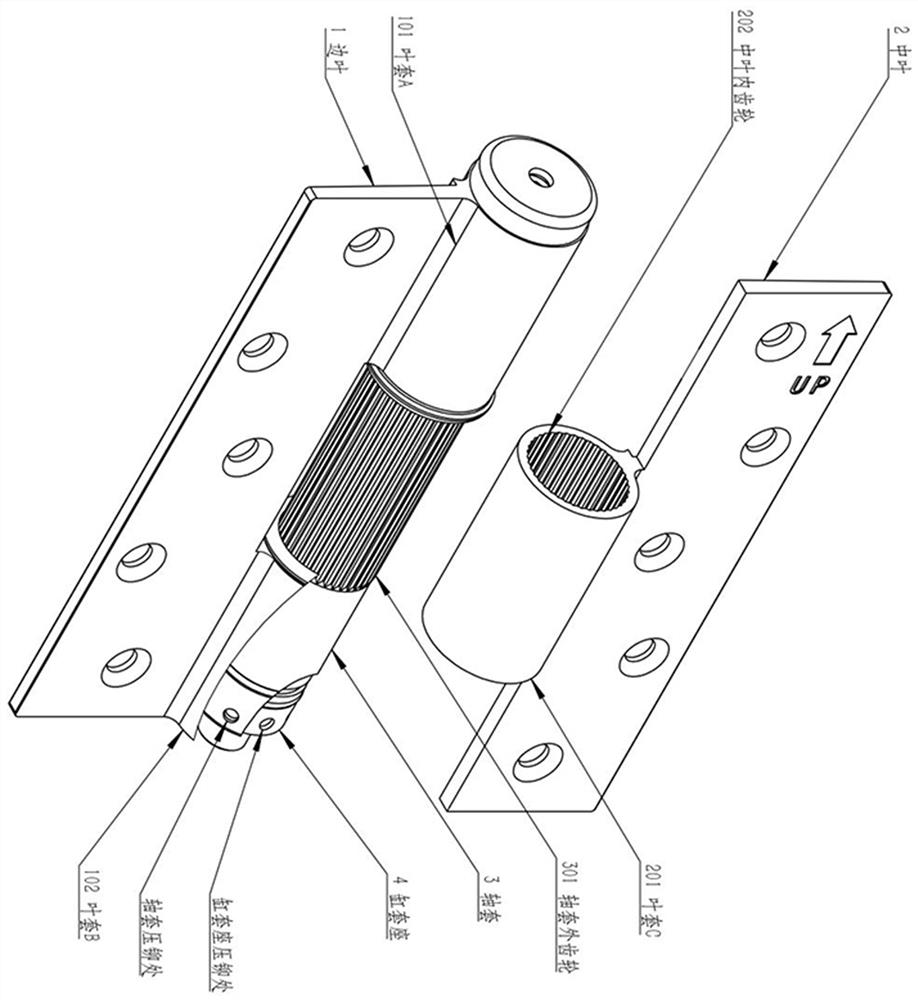

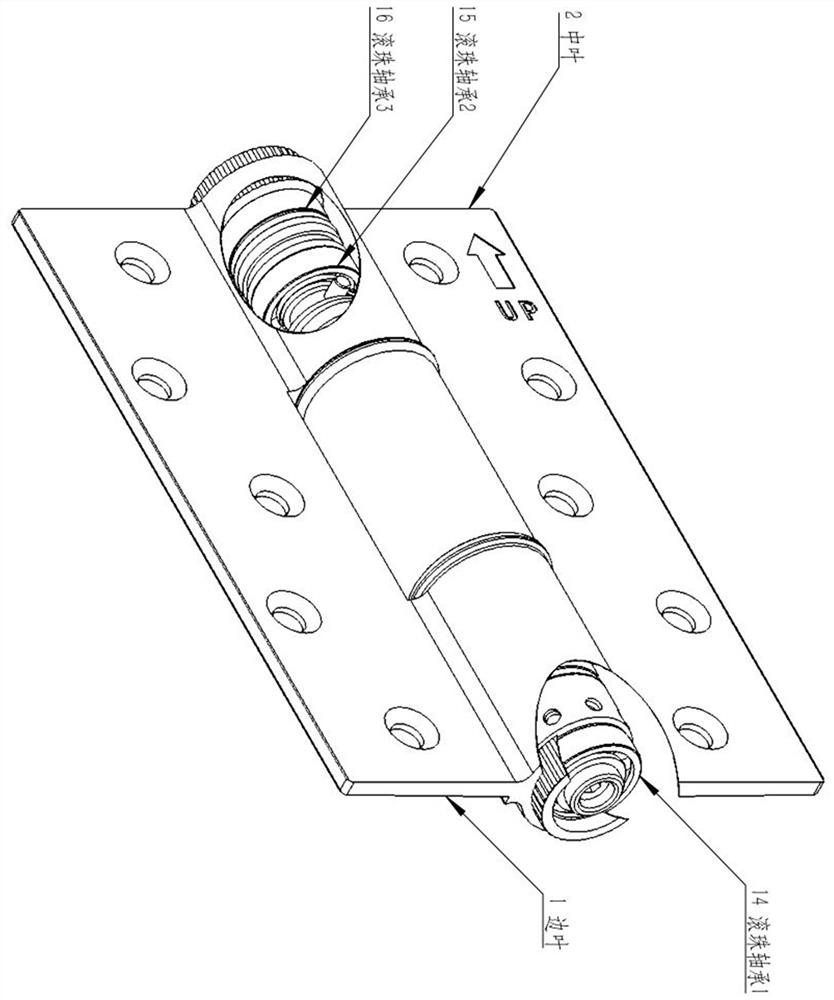

[0015] As shown in Figures 1, 2, 3, and 4, the present invention includes side leaves, middle leaves, pressure springs, shaft sleeves, cylinder sleeves, shaft cores and cylinder cores; The leaf sleeve B is combined with the upper bushing gear sleeve. The inside of the blade sleeve C is the middle leaf internal gear, which is fitted and fixed with the outer gear in the middle part of the shaft sleeve. The blade sleeve A and the blade sleeve C are connected by the pressure bearing 2, and the blade sleeve B and leaf sleeve C are connected by pressure bearing 3, end cover 1 is connected with the upper lining gear sleeve at the bottom, and end cover 2 is connected with the connecting gear sleeve at the top, which together constitute the external structure of the door hinge; the shaft sleeve and the cylinder sleeve The seat is connected by ring-fitting pressure riveting, and the pressure riveting position is at the upper end of the ball bearing shaft 1; the top of the shaft core is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com