Intelligent ventilation and illumination system for factory building

A technology for workshops and fans, applied in the field of ventilation systems, can solve problems such as energy waste, and achieve the effects of reducing dust, improving utilization, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

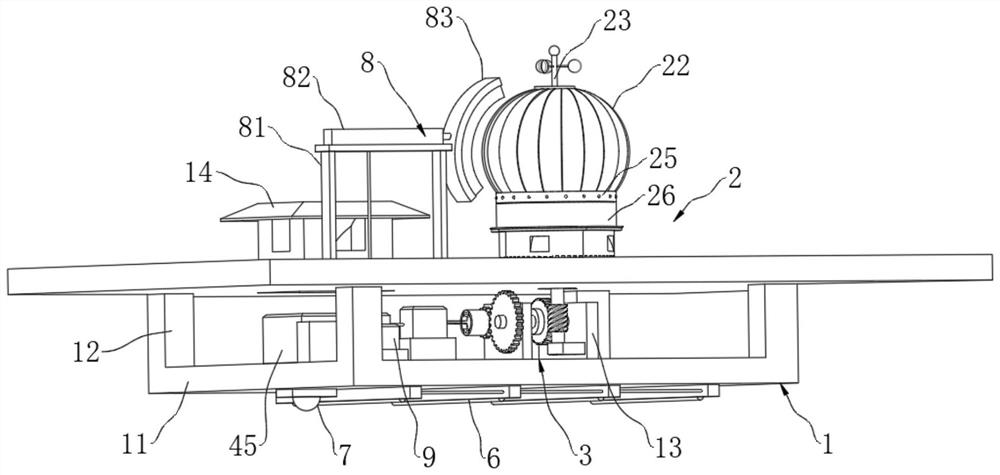

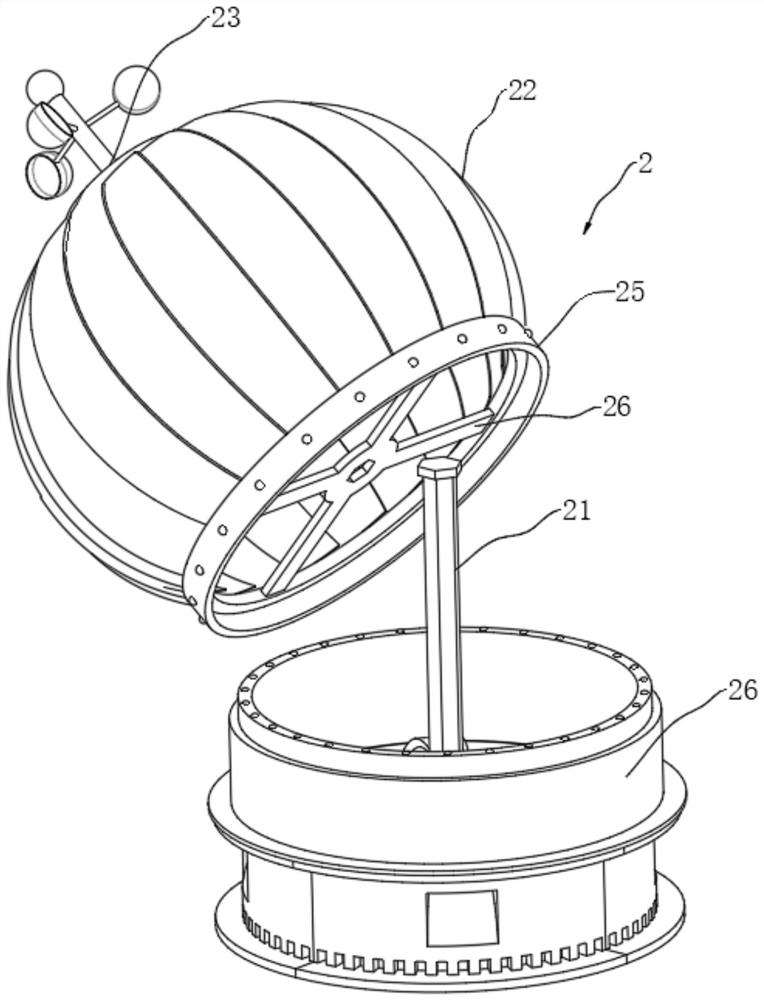

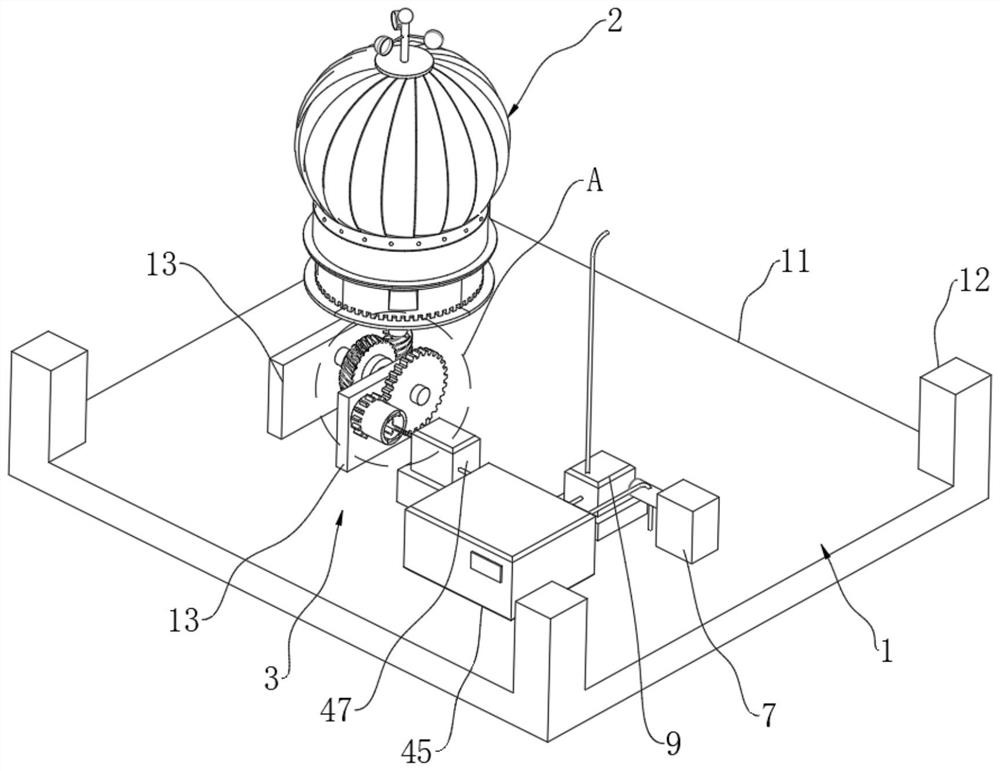

[0024] The embodiment disclosure of the present application provides an intelligent system for factory building ventilation and lighting. By using the non-powered fan 2 to convert the energy generated by the rotation of the main shaft 21 when the non-powered fan 2 is rotating, the kinetic energy of the non-powered fan 2 is passed through the transmission mechanism. 5 is transmitted to the power generating mechanism 4, and the kinetic energy of the non-powered fan 2 is converted into electric energy by the power generating mechanism 4 and stored, which solves the problem of energy waste caused by the continuous operation of the non-powered fan 2 in the prior art, and realizes the effective improvement of resources. Utilization rate, the effect of reducing the waste of energy when the unpowered blower fan 2 is running.

[0025] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com