Silicon wafer turning device for silicon wafer electrode printing

A technology of electrode and flipping, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc. It can solve the problems of reducing the efficiency of silicon wafer printing flipping, time-consuming and laborious, and the production efficiency of silicon wafer printing products, etc., to achieve convenient and automatic fixing , improve flipping efficiency, and improve the effect of diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

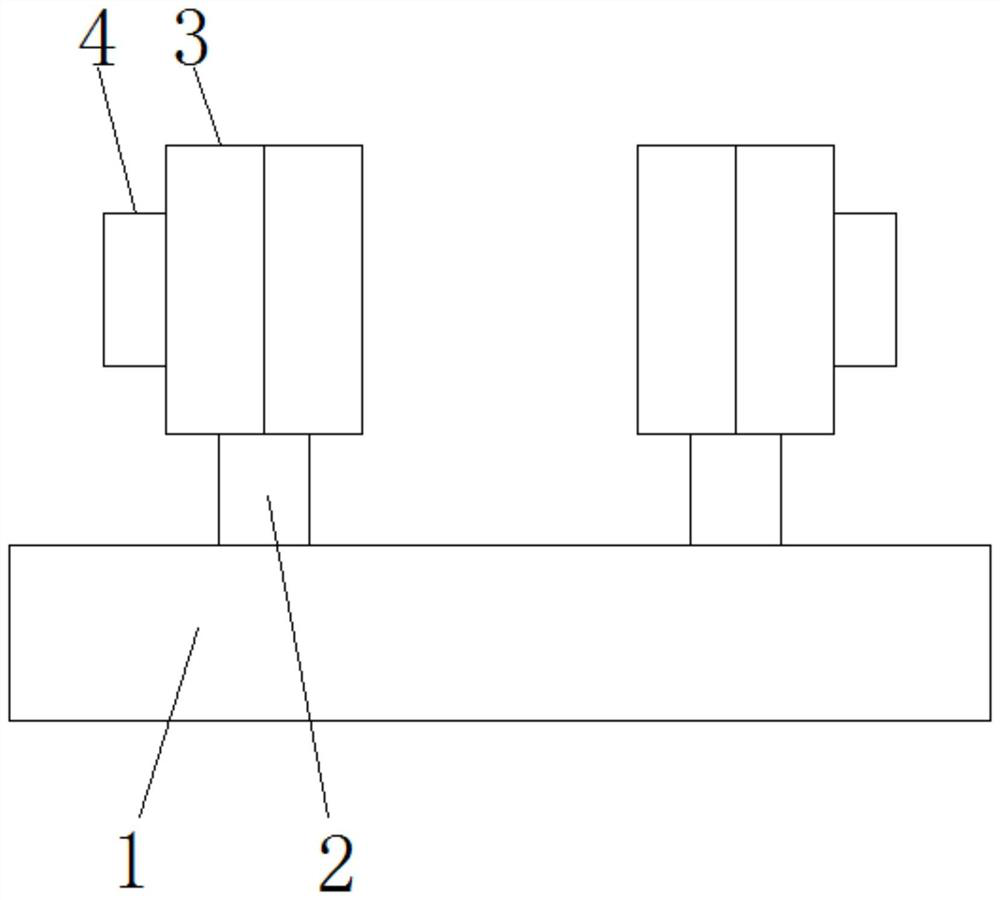

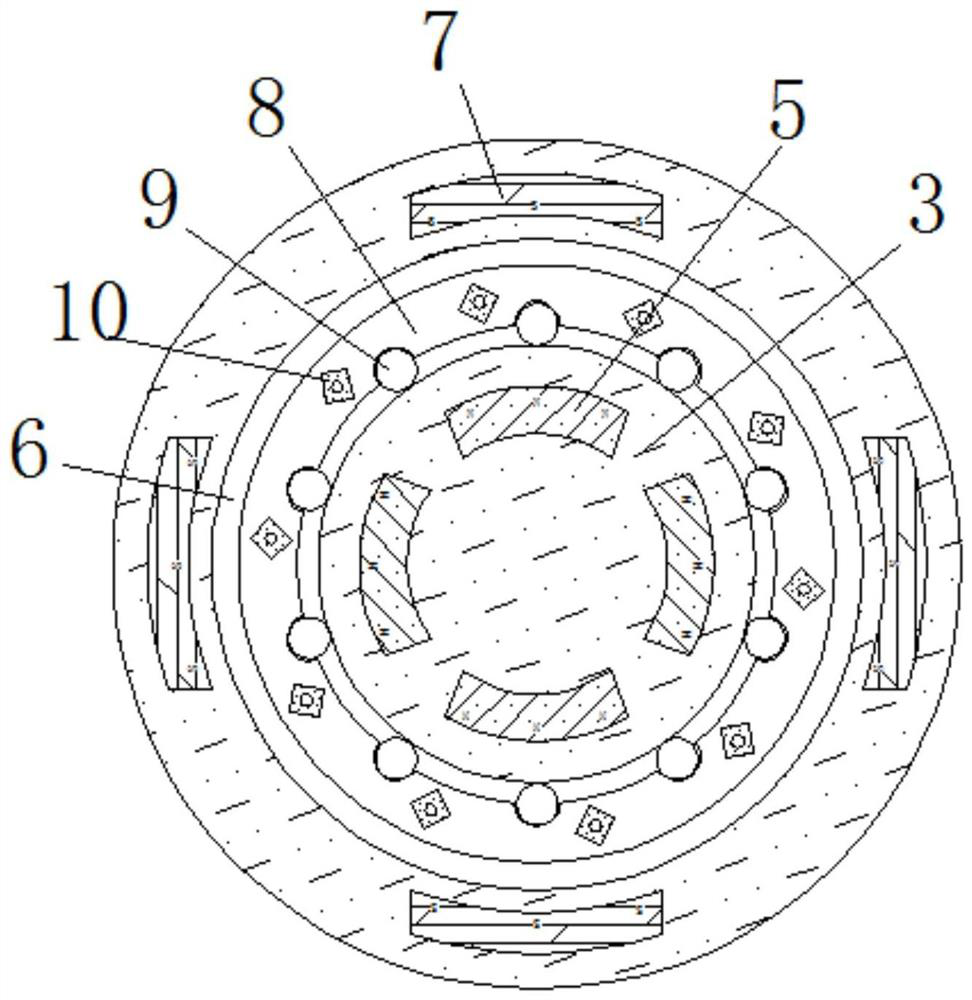

[0026] Embodiment one, by Figure 1-6 Given, the present invention includes a flipping device for silicon wafer electrode printing, including a working platform 1, the top of the working platform 1 is fixedly connected with a support column 2, and the outer side of the support column 2 is fixedly connected with a fixed plate 3, and the fixed plate The inwall of 3 is movably connected with rotating disk 4, the inwall of fixed disk 3 is fixedly connected with magnet one 5, the inwall of fixed disk 3 is provided with ring groove 6, the inwall of fixed disk 3 and the outside near ring groove 6 is fixedly connected with magnet two 7. The magnetism of the opposite surface of magnet one 5 and magnet two 7 is opposite, the quantity of magnet one 5 is the same as the quantity of magnet two 7, and magnet one 5 and magnet two 7 have played the effect of generating magnetic field;

[0027] The inner side of the ring groove 6 is movably connected with a swivel 8, and the swivel 8 plays the...

Embodiment 2

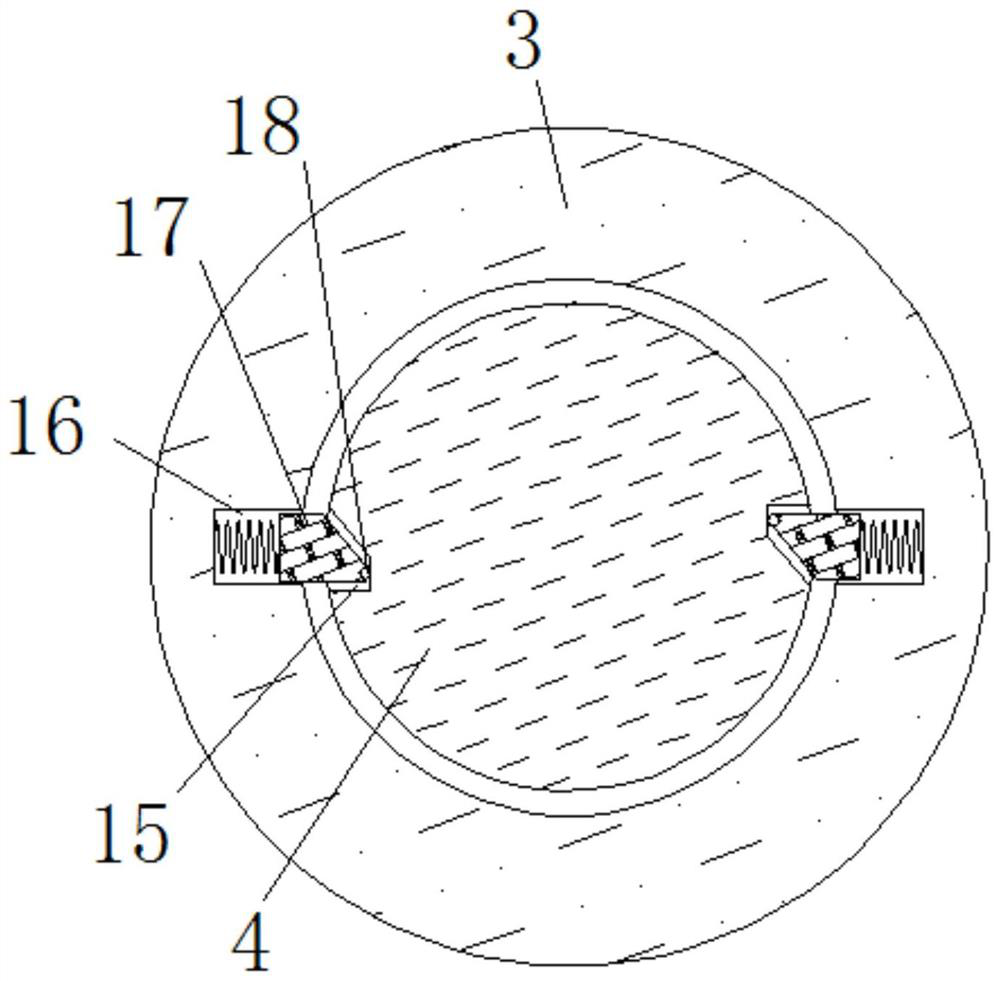

[0030] Embodiment 2. On the basis of Embodiment 1, the present invention includes a flipping device for electrode printing on silicon wafers, including a working platform 1. The top of the working platform 1 is fixedly connected with a supporting column 2, and the outer side of the supporting column 2 is Fixedly connected with a fixed disk 3, the inner wall of the fixed disk 3 is movably connected with a rotating disk 4, the inner wall of the fixed disk 3 is fixedly connected with a magnet-5, the inner wall of the fixed disk 3 is provided with a ring groove 6, and the inner wall of the fixed disk 3 is close to the ring. The outside of groove 6 is fixedly connected with magnet two 7, and the magnetism of the opposite surface of magnet one 5 and magnet two 7 is opposite, and the quantity of magnet one 5 is identical with the quantity of magnet two 7, and magnet one 5 and magnet two 7 have played the effect of generating magnetic field effect;

[0031] The inner side of the ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com