Oil cylinder rod head machining clamp with bottom supported in suspended mode

A cylinder rod and fixture technology, applied in the field of cylinder rod head processing fixtures, can solve problems such as troublesome and unsupported overturning, and achieve the effect of reducing the operation process, improving the processing accuracy, and having a good fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

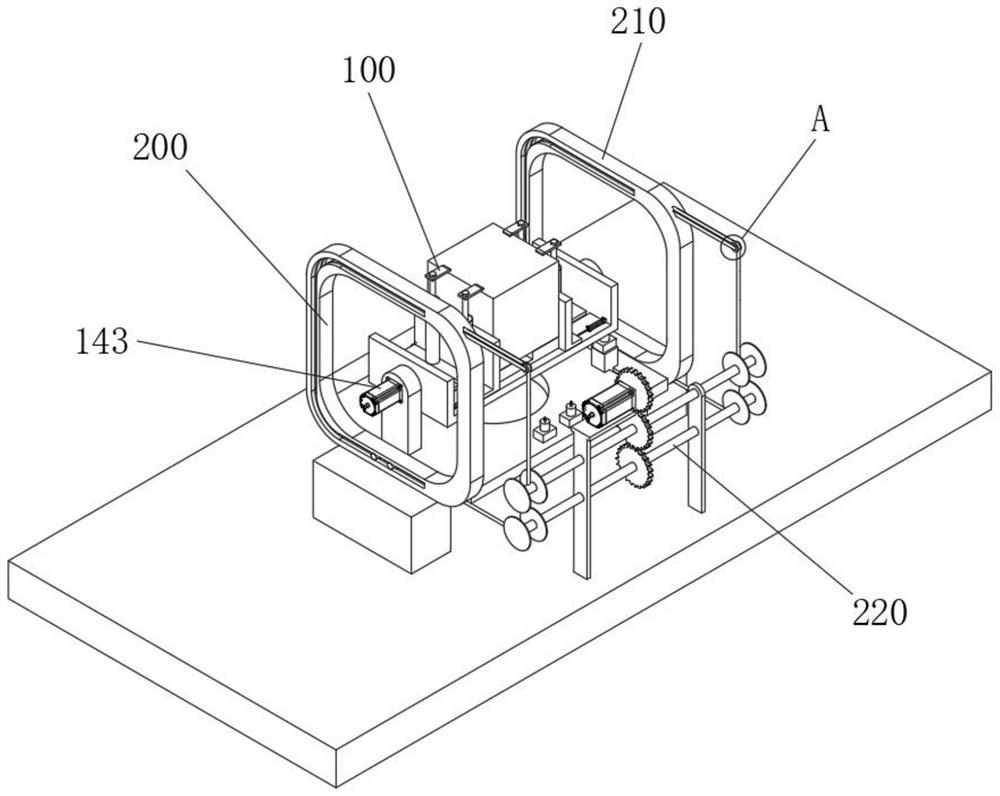

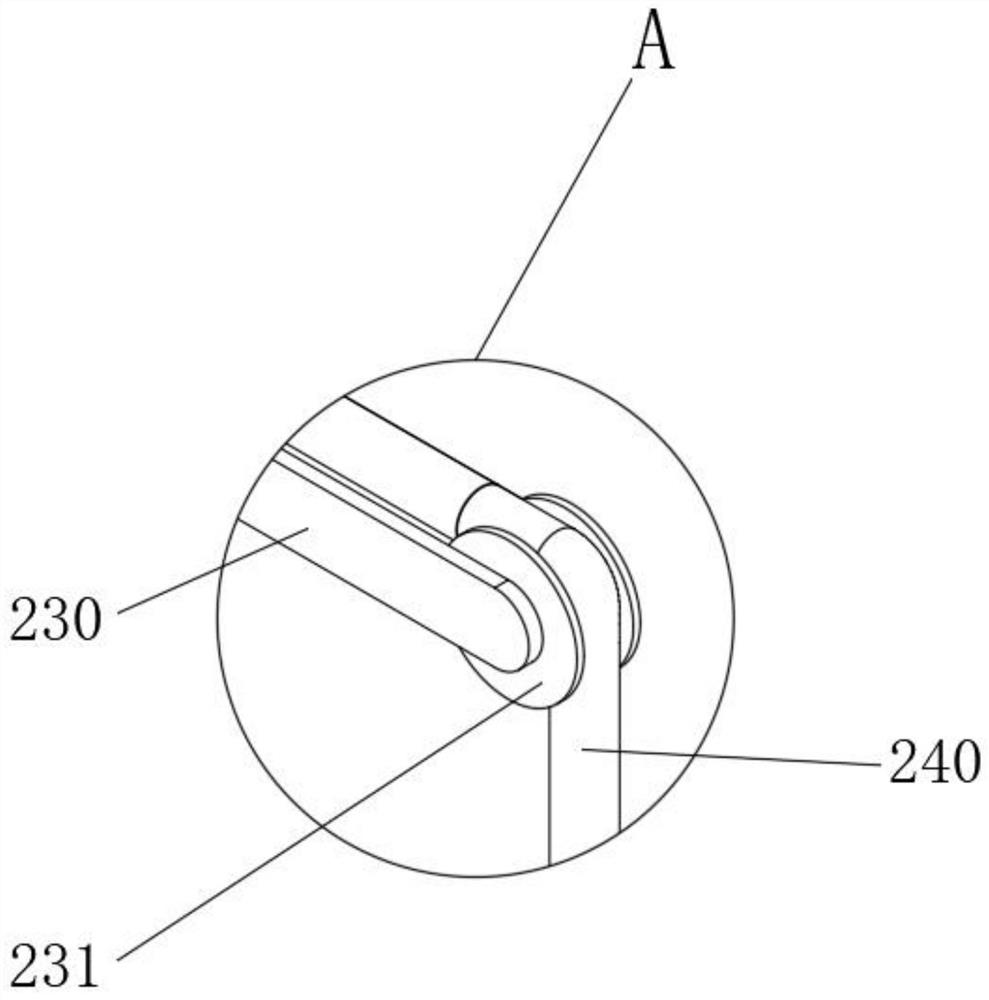

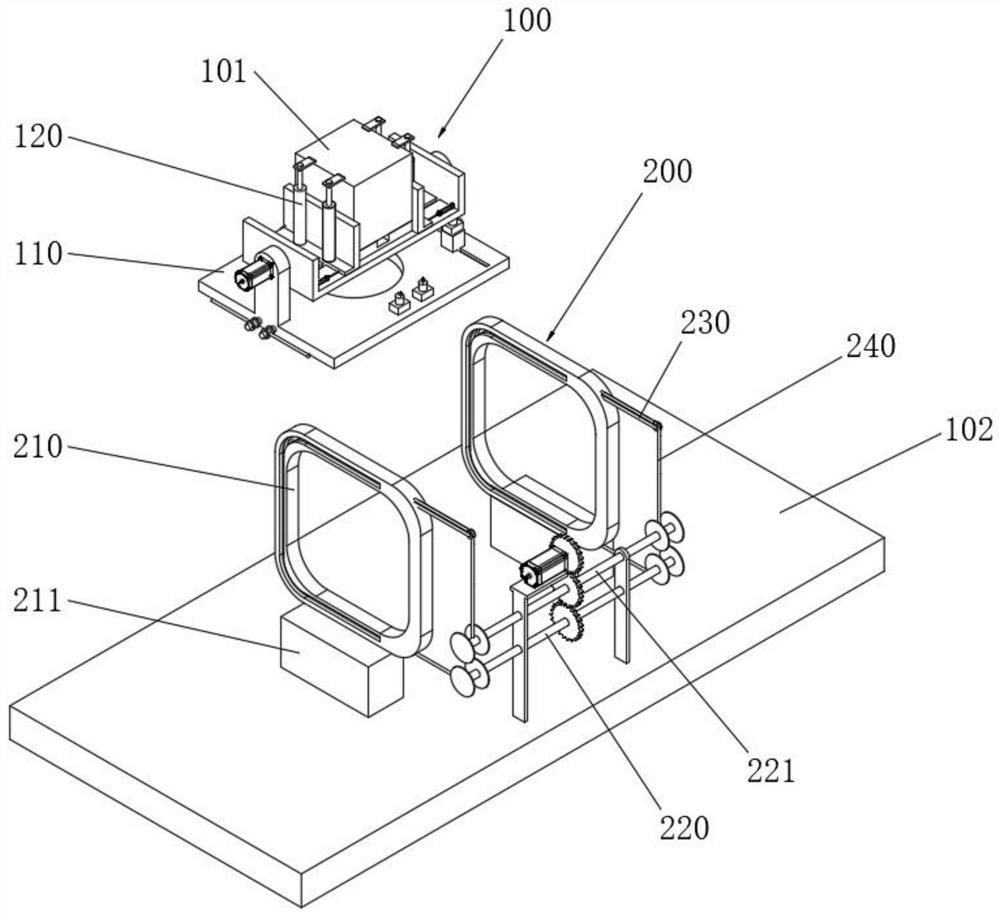

[0049] See Figure 1 - Figure 10 , The cylinder head is provided with a jig machining the bottom of truss-supported, 200, the clamping device comprises a clamping means 100 and the turnover device 100 is mounted on the fixture 100 includes at least:

[0050] Web 140, web 140 defines a circular hole 145 at the center, the connecting plate 140 is provided above the fixing plate 130, post 135 is provided below the stationary transfer plate 130, in turn connected to post 135 rotates the circular hole 145, 130 above the fixed plate Shen defines a groove 131, a base for receiving the cylinder head, the sink 132 defines a plurality of grooves 131 machined hole, for guiding a drill bit;

[0051] Clamp 120, clamp 120 is provided below the slider 124, the upper connecting plate 140 defines a sliding groove 141, the slide block 124 is slidably connected within the sliding groove 141, rotating cylinder 120 is provided with side clamp 121, preferably a high-pressure type, to enhance the accurac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com