Method for producing hydrogen by electrolyzing water under driving of offshore wind power

A technology of offshore wind power and electrolysis of water, which is applied in the direction of wind power generation, electrolysis process, electrolysis components, etc., can solve the problems of difficult maintenance and high cost of transmission lines, and achieve the effects of alleviating energy demand pressure, being environmentally friendly, and avoiding power difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

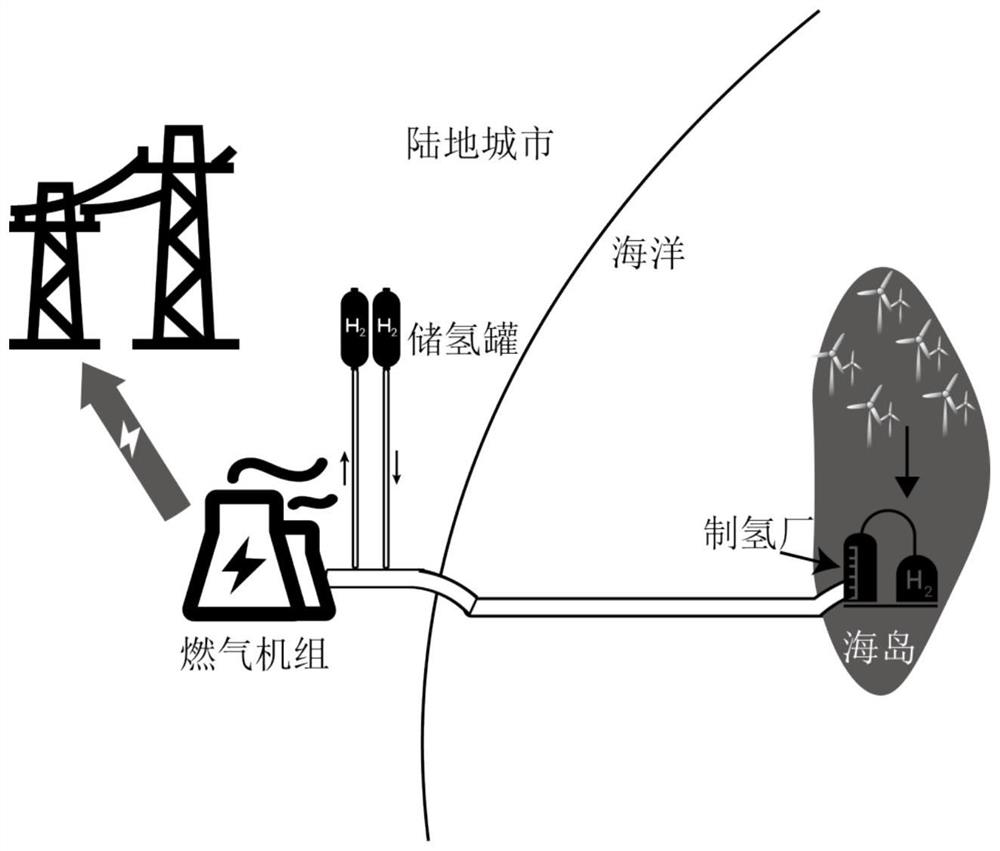

[0068] A method for producing hydrogen by electrolysis of water driven by offshore wind power, comprising the following steps:

[0069] S1. Build a hydrogen production plant on an island, and use offshore wind power to drive hydrogen production; calculate the real-time hydrogen production rate based on the power generated by the wind farm, and calculate the maximum hydrogen production flow in a day based on the real-time hydrogen production rate, and build a production facility of a corresponding scale hydrogen plant.

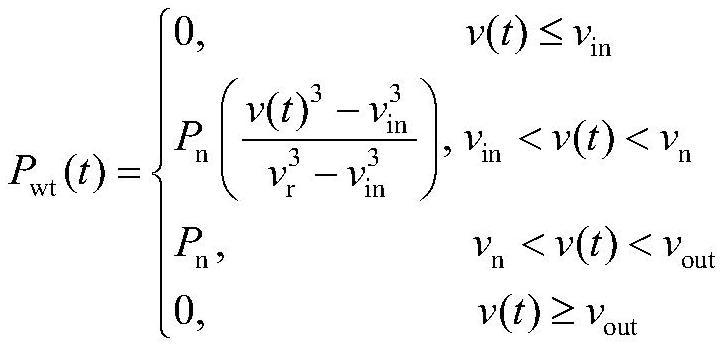

[0070] According to the installed capacity of the offshore wind farm and the wind speed, calculate the power generation of the wind farm:

[0071]

[0072] P wt (t) is the actual output power of the offshore wind farm at time t (kW);

[0073] P n is the rated power of the offshore wind farm (kW);

[0074] v(t) is the wind speed (m / s) that the offshore wind farm can capture at time t;

[0075] v in is the cut-in wind speed of the wind turbine (m / s);

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com