Method for manufacturing mold for fine metal mask manufacturing and method for manufacturing fine metal mask

A fine metal mask and mold manufacturing technology, which is applied in the direction of manufacturing tools, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as alignment problems, technical limitations, and manufacturing process difficulties, so as to reduce process costs, The effect of improving manufacturing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] best practice

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, the embodiments of the present invention can be modified into various other forms, and the scope of the present invention is not limited to the embodiments described below. Embodiments of the present invention are provided to more completely explain the present invention to those having ordinary knowledge in the technical field. In the drawings, components having a specific pattern or a predetermined thickness are shown, but this is for convenience of description or distinction, and therefore even mentioning a specific pattern and a specific thickness is not limited to the configuration shown in the present invention. feature of the element.

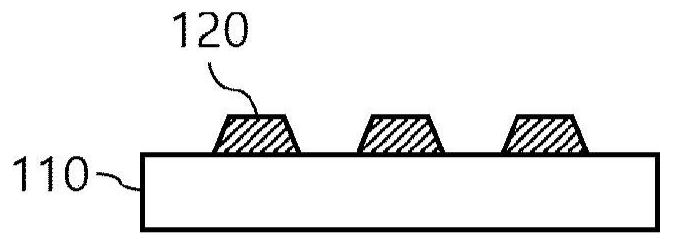

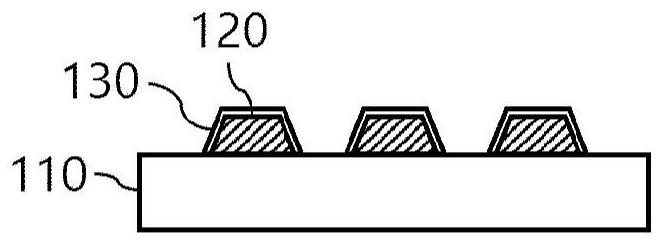

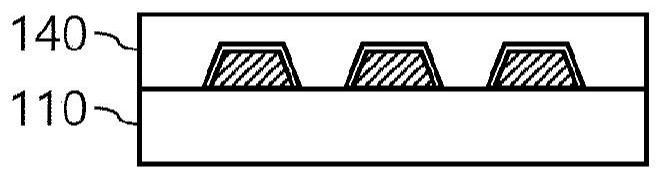

[0033] Figure 1 to Figure 5 It is a figure provided in the description of the mold manufacturing method for fine metal mask manufacturing according to one embodiment of the present invention. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com