Electric curtain control device

A technology for control devices and electric curtains, which is applied to window decorations, applications, home appliances, etc., can solve the problems of easy cross-influence, poor user experience, and poor product stability during pressing operations, so as to avoid poor product stability. , Simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

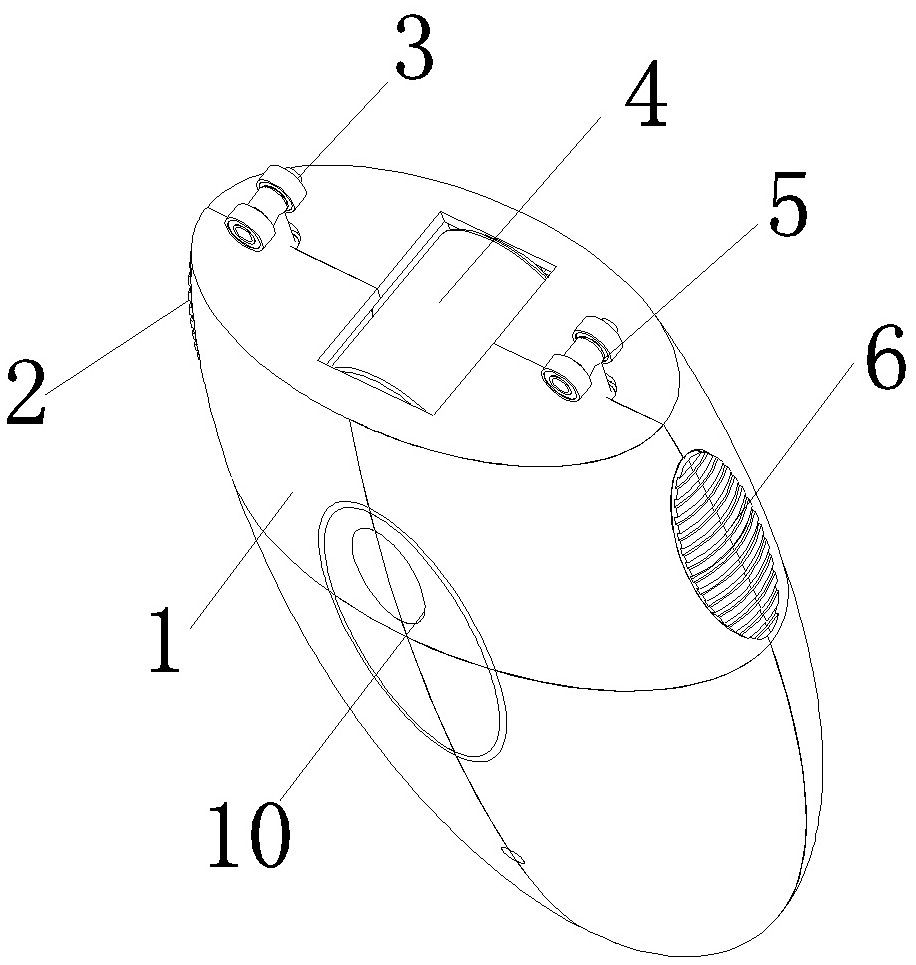

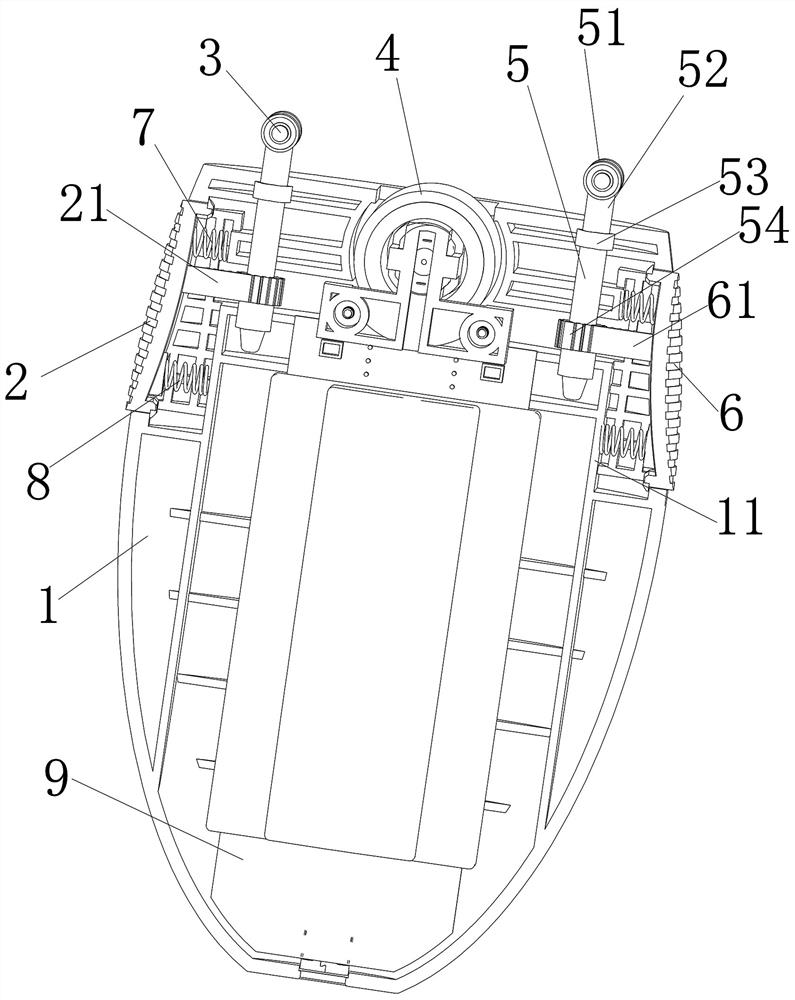

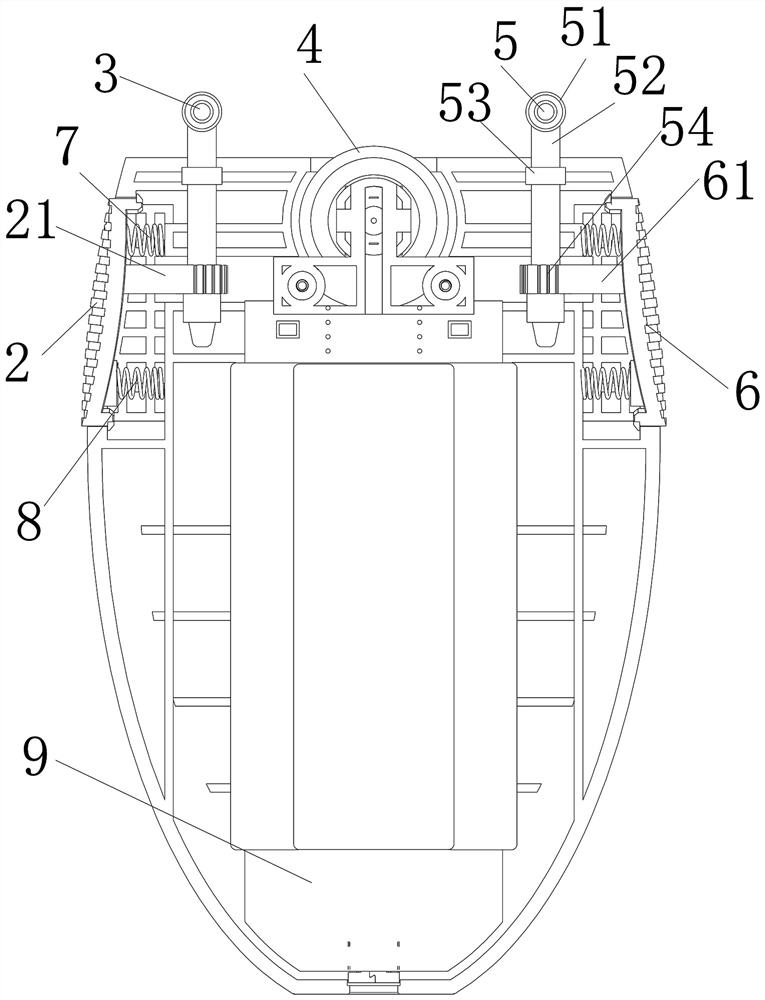

[0077] The structure of the electric curtain control device in the present embodiment is as follows: Figures 1 to 9 As shown, the electric curtain control device is used to cooperate with the internal type track. The curtain control device as a whole includes a housing 1, and the top of the housing 1 is provided with a driving wheel 4, a front driven wheel assembly 3 and a rear driven wheel assembly 5. Most of the driving wheel 4 is located inside the housing, and a small part protrudes from the top of the housing 1, so as to roll and press fit with the lower side of the bottom wall of the inner-shaped track. The front driven wheel assembly 3 and the rear driven wheel assembly The driven wheel 51 on the top of the component 5 protrudes upwards, and is used to extend into the inner cavity of the inner-shaped track, and roll and press fit with the upper side of the bottom wall of the inner-shaped track.

[0078] The structures of the front side driven wheel assembly 3 and the r...

specific Embodiment 2

[0094] It differs from Embodiment 1 mainly in that: in Embodiment 1, both the front transmission mechanism and the rear transmission mechanism are rack and pinion mechanisms. In this embodiment, the front transmission mechanism and the rear transmission mechanism can also be link transmission mechanisms, the link transmission mechanism includes a connecting rod, a transmission disc is arranged on the wheel shaft, one end of the connecting rod is hinged with the transmission disc, and the other end is connected with the assembly The button is hinged. When the button is moved forward and backward, the connecting rod can drive the transmission plate to rotate, and then drive the wheel shaft to rotate back and forth.

[0095] It should be noted that when using the linkage mechanism, attention should be paid to avoid dead point problems, for example: if the rotating shaft reaches the assembly and disassembly position when it is rotated 90° from the working position, the linkage can ...

specific Embodiment 3

[0098] The main difference between it and Embodiment 1 is that in Embodiment 1, the mounting and dismounting buttons on both sides respectively drive the two axles of the driven wheel assembly on both sides to rotate synchronously through different transmission mechanisms. In this embodiment, the axles of the driven wheel assemblies on both sides can be driven by the combined force of the mounting and dismounting buttons on both sides through the synchronous transmission mechanism. The synchronous transmission mechanism here is a rack and pinion transmission mechanism, and the rack and pinion mechanism includes two The two gears on the wheel shaft, the front gear fixedly connected with the front side installation and removal button, the rear side gear fixedly connected with the rear side installation and removal button, the front side gear meshes with the two gears on the two wheel shafts respectively, and the rear side gear is fixedly connected with the rear side installation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com