Die for accessory forming machining

A technology of molding processing and mould, which is applied in the field of molds for accessories molding processing, can solve the problems of not easy to transmit noise and aggravate the difficulty of cleaning the staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

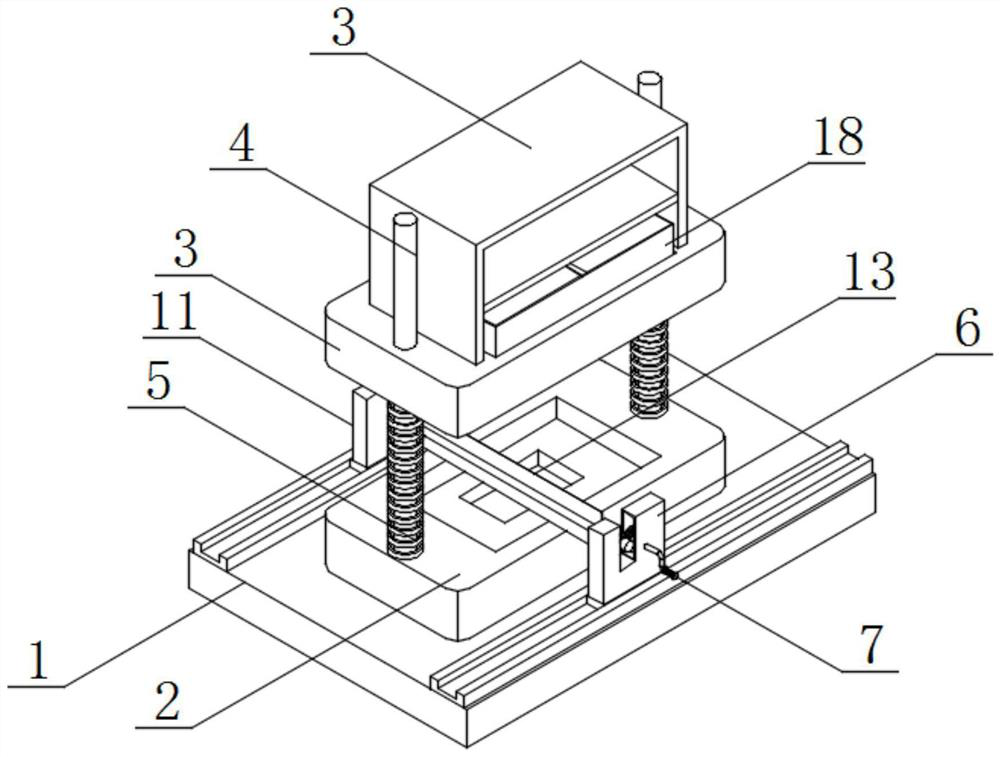

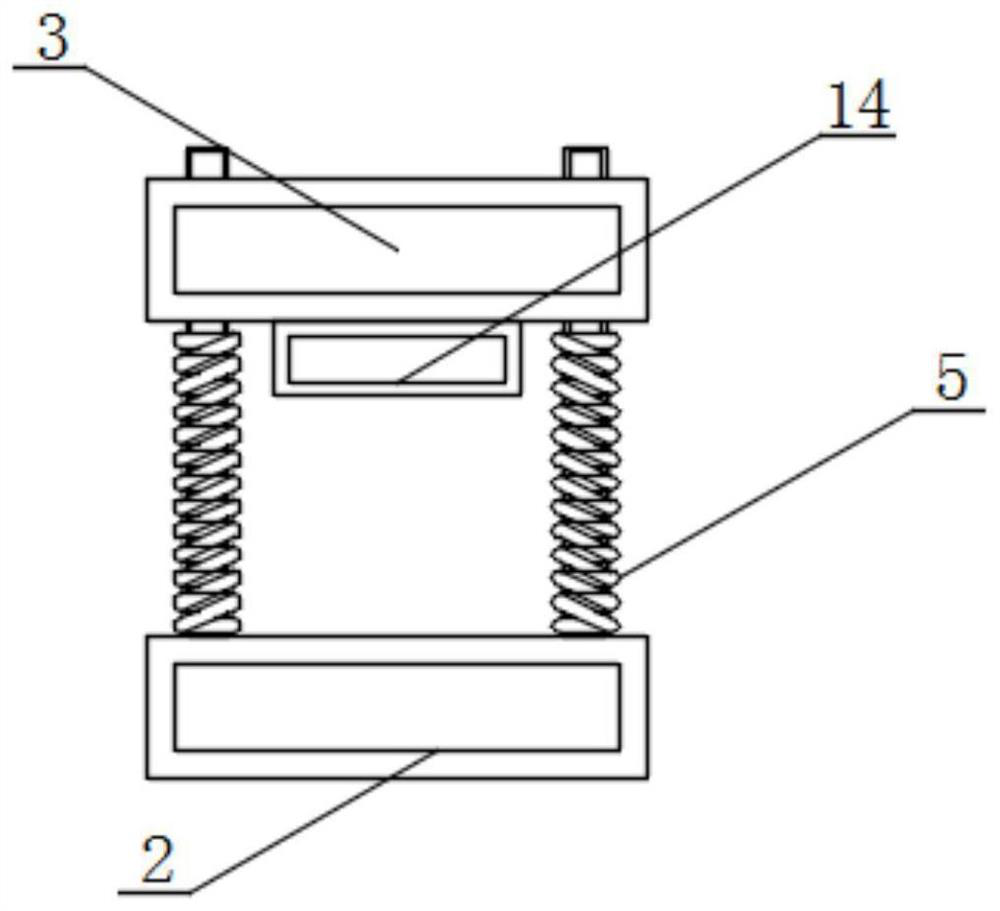

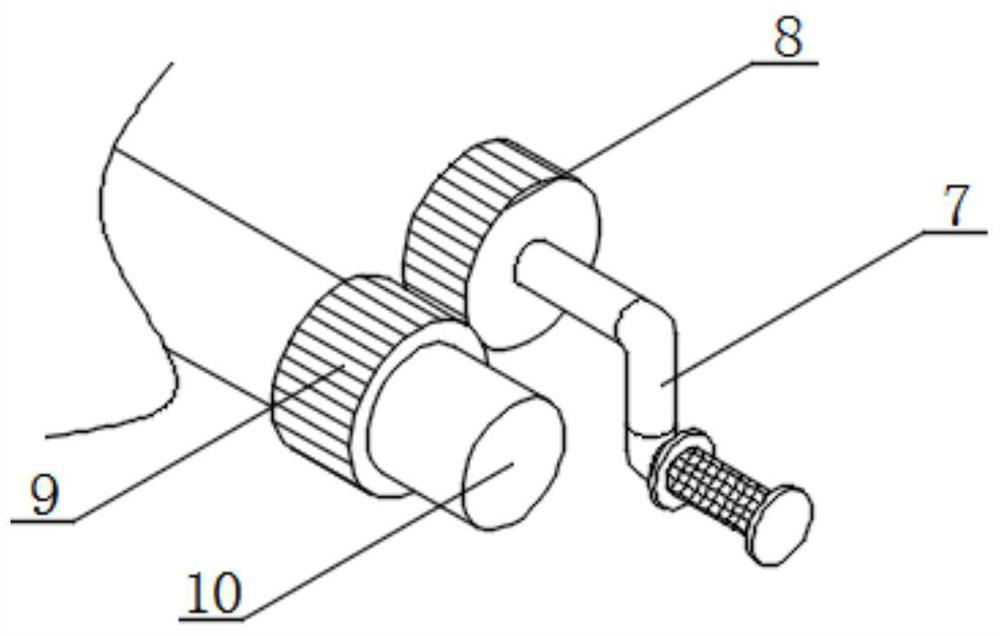

[0027] see figure 1 , figure 2 , image 3 and Figure 5 , an embodiment provided by the present invention, a mold for molding accessories, including a bottom plate 1, a lower mold 2 and an upper mold 3, the top of the bottom plate 1 is provided with a lower mold 2, and both sides of the top of the lower mold 2 are provided with A fixed rod 4, a compression spring 5 runs through the surface of the fixed rod 4, an upper mold 3 is connected to the top of the compression spring 5, a slide rail a is installed on one side of the top of the bottom plate 1, and a slide block a is slidably connected to the inside of the slide rail a, The top of the slider a is provided with a fixed block a6, one side of the fixed block a6 runs through a hand crank 7, the surface of the hand crank 7 runs through a driving gear 8, and the surface of the driving gear 8 is meshed with a driven gear 9. The inside of the gear 9 runs through a rotating rod 10, and the other side of the top of the bottom p...

Embodiment 2

[0031] see figure 1 and Figure 4 , an embodiment provided by the present invention is a mold for accessory molding and processing, a support frame 15 is installed on the top of the upper mold 3, a horizontal plate is installed on the inner side wall of the support frame 15, and a telescopic cylinder 16 is arranged on the top of the horizontal plate. The bottom end of the telescopic cylinder 16 is connected with a pressing plate 17, and the top of the upper mold 3 is provided with an insertion groove, and a cutting frame 18 runs through the inside of the insertion groove;

[0032] The setting of the supporting frame 15, the horizontal plate, the telescopic cylinder 16, the pressing plate 17, the cutting frame 18 and the insertion groove, when the accessories are pressed and formed under the action of the upper mold 3 and the lower mold 2, there will be redundant parts at the corners. The raw material adheres to the edge of the formed product. At this time, the telescopic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com