Lever type rigidity-variable flexible joint based on cam

A flexible joint and lever-type technology, applied in the field of robotics, can solve the problems of changing rigid structure, narrow rigidity adjustment range, and large joint size, etc., and achieve the effect of various installation methods, continuous adjustment of stiffness, and reduced axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

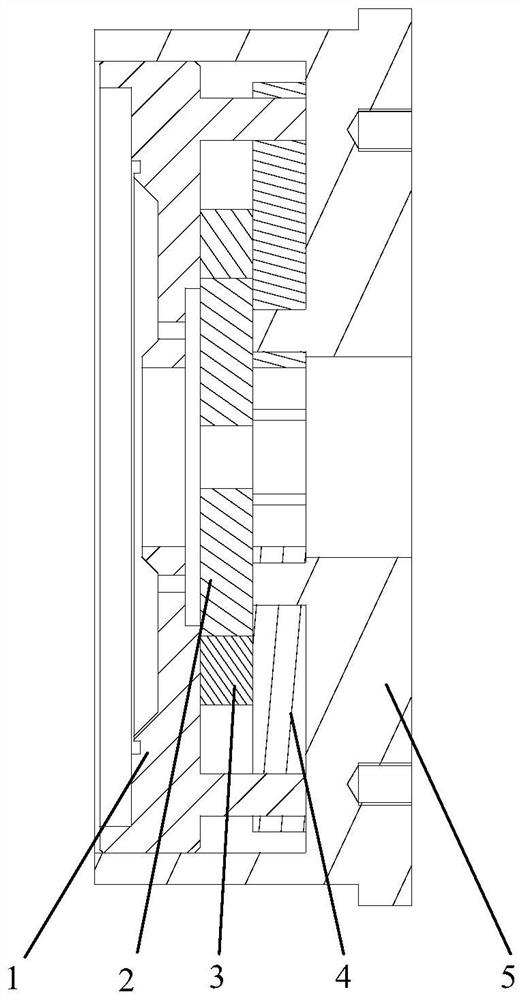

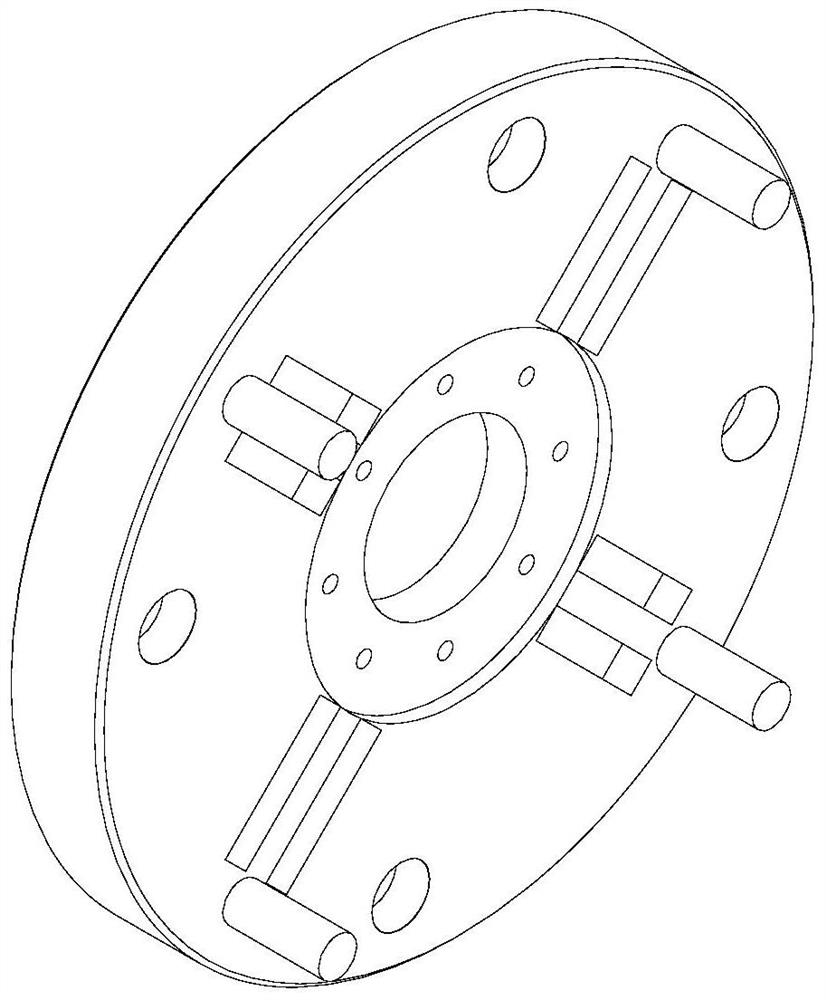

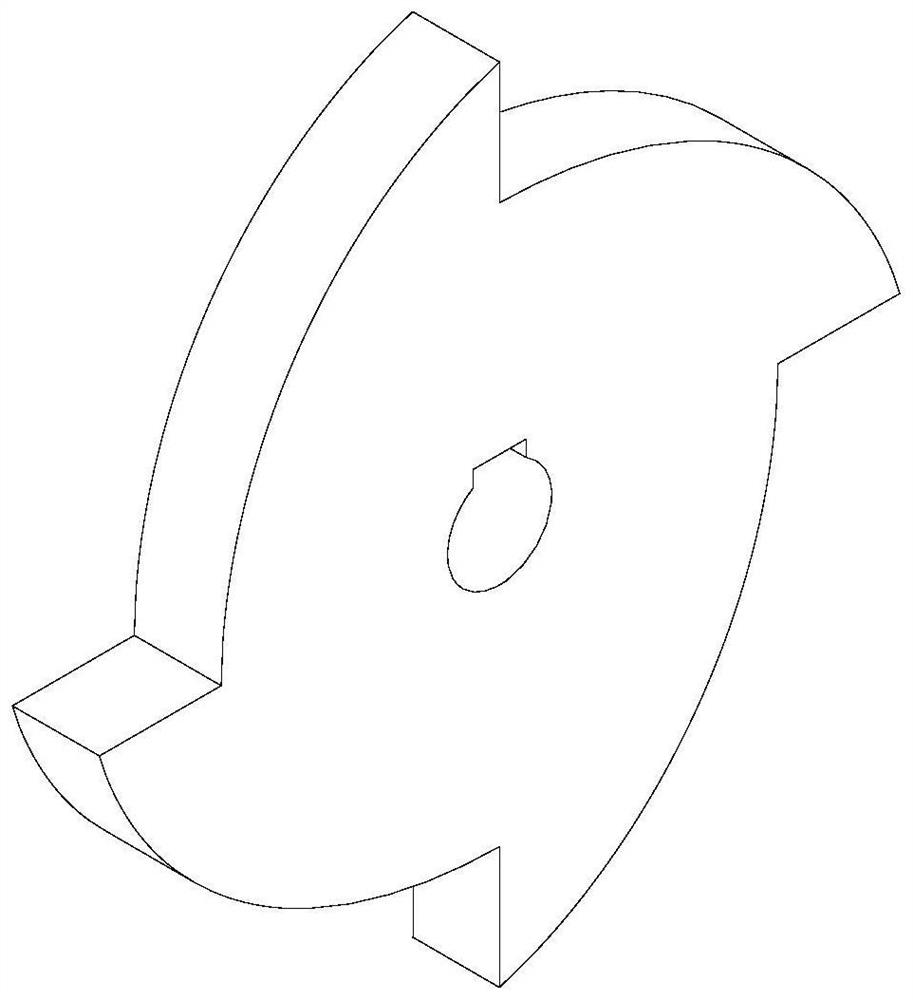

[0037] Such as Figure 7-8 It is a schematic diagram and a sectional view of the installation method of a variable stiffness mechanism and an integrated drive mechanism of a cam-based lever type variable stiffness flexible joint of the present invention. The drive motor 10 drives the drive disc 1 to rotate through the harmonic reducer 9, the stiffness adjustment motor 13 drives the cam disc 2 through the stiffness adjustment motor output shaft 11, and the cam disc 2 and the stiffness adjustment motor output shaft 11 Cooperate, the casing of the stiffness adjustment motor 13 and the casing of the driving motor 10 are fixedly connected. The said stiffness adjustment motor is placed in front, that is, the stiffness adjustment motor is placed at the front end of the integrated drive mechanism. A hollow shaft is arranged inside the integrated drive mechanism 6 . The drive disc 1, the cam disc 2 and the output disc 5 cooperate with the stiffness adjustment motor output shaft 11; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com