Method for preparing complex soft structure by using water-soluble template

A water-soluble template and soft structure technology, which can be used in coatings and other directions to solve the problems of unstable mechanical properties, harsh processing conditions, and high temperature of complex soft structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

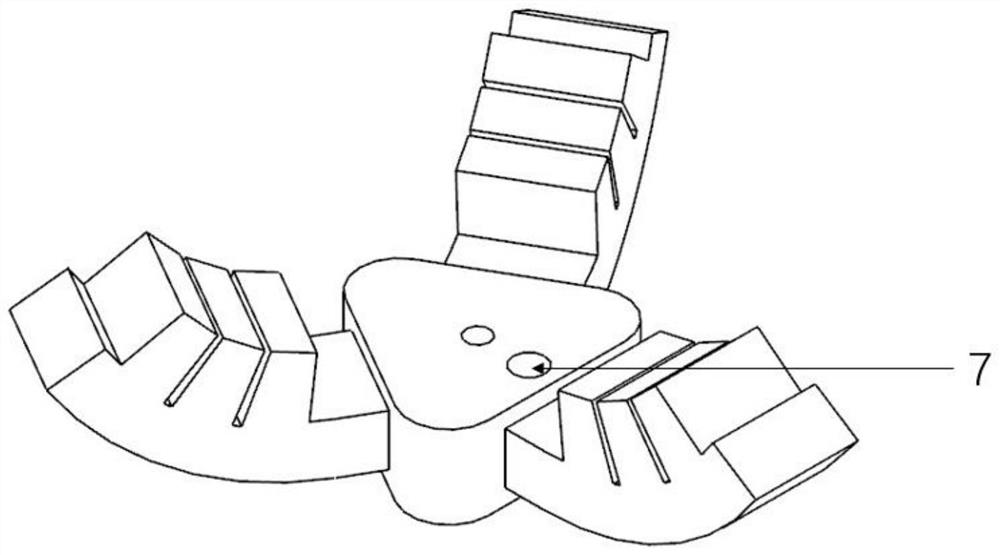

[0048] This embodiment provides a method for preparing a complex soft body structure using a water-soluble template. Taking a soft gripper as an example, its structural diagram is as follows figure 1 Shown, its preparation method comprises the following steps:

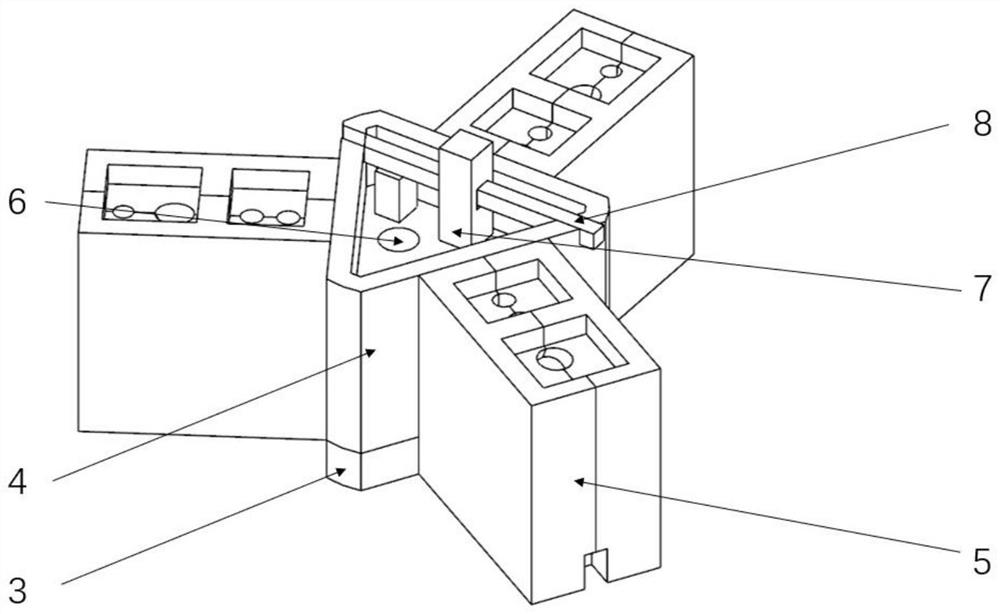

[0049] (1) According to figure 1 The outer contour of the soft body structure is shown, and a non-water-soluble hard outer cavity mold 1 is designed, and its structural schematic diagram is as follows figure 2 As shown, the hard outer cavity mold 1 is divided into two parts: an upper mold 2 and a lower mold 3. The upper mold is composed of a central mold 4 and a left and right mold 5. The central mold 4 is in the center, and a gate 6 and a melting channel 7 are left in it. And buckle 8; using SLS selective laser sintering technology to manufacture hard outer cavity mold 1, the material selected is HP 7500 high-performance nylon;

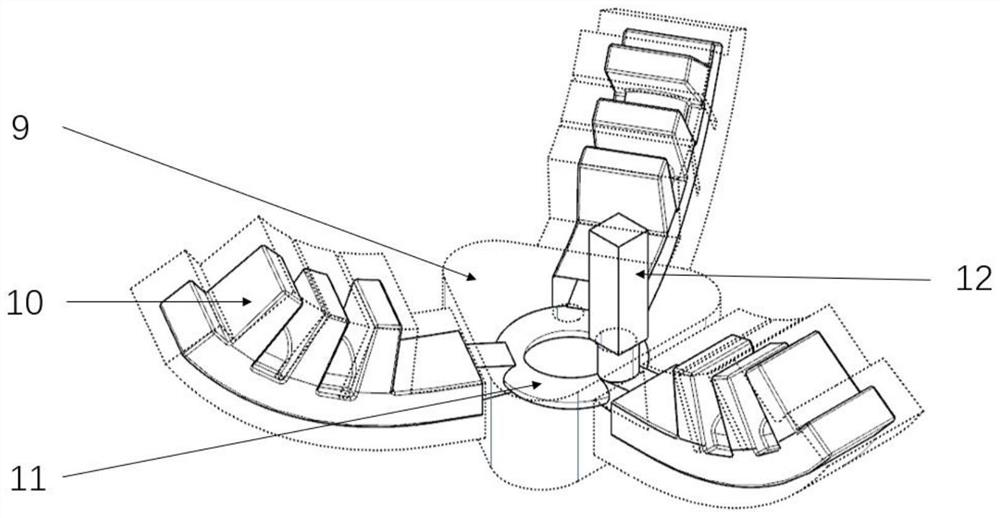

[0050] according to figure 1 As shown in the internal outline of the soft body struct...

Embodiment 2

[0055] This example provides a method for preparing a complex soft body structure using a water-soluble template. For details, see Example 1. The difference is that the preparation method of the non-water-soluble hard outer cavity mold in step (1) is SLA light-curing molding. The material is BASF ST45 tough resin.

Embodiment 3

[0057] This example provides a method for preparing a complex soft body structure by using a water-soluble template. For details, refer to Example 1. The difference is that the curing temperature in step (3) is 73° C., and the curing time is 9 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com