Assembly type multifunctional roof structure

A prefabricated and multi-functional technology, applied in the direction of roof, roof covering, building roof, etc., can solve the problems of not considering the function of sound insulation, reduce living comfort, temperature rise, etc., to enhance the thermal insulation effect, The effect of shortening construction period and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

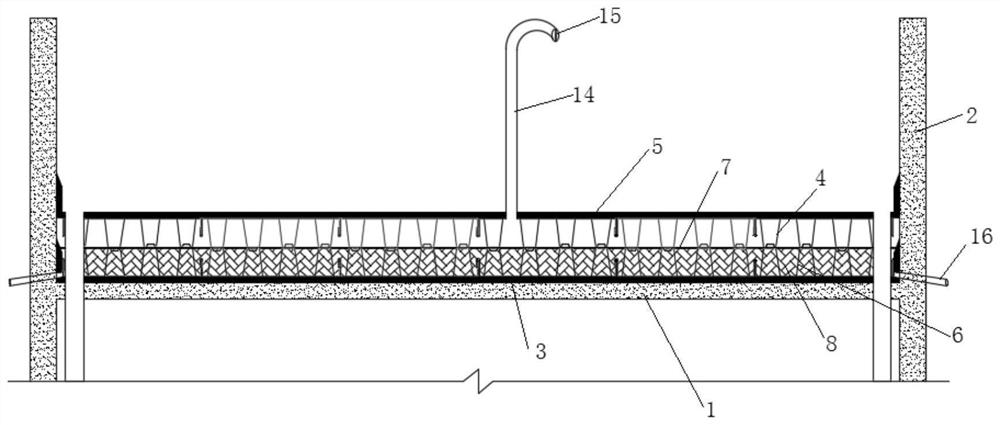

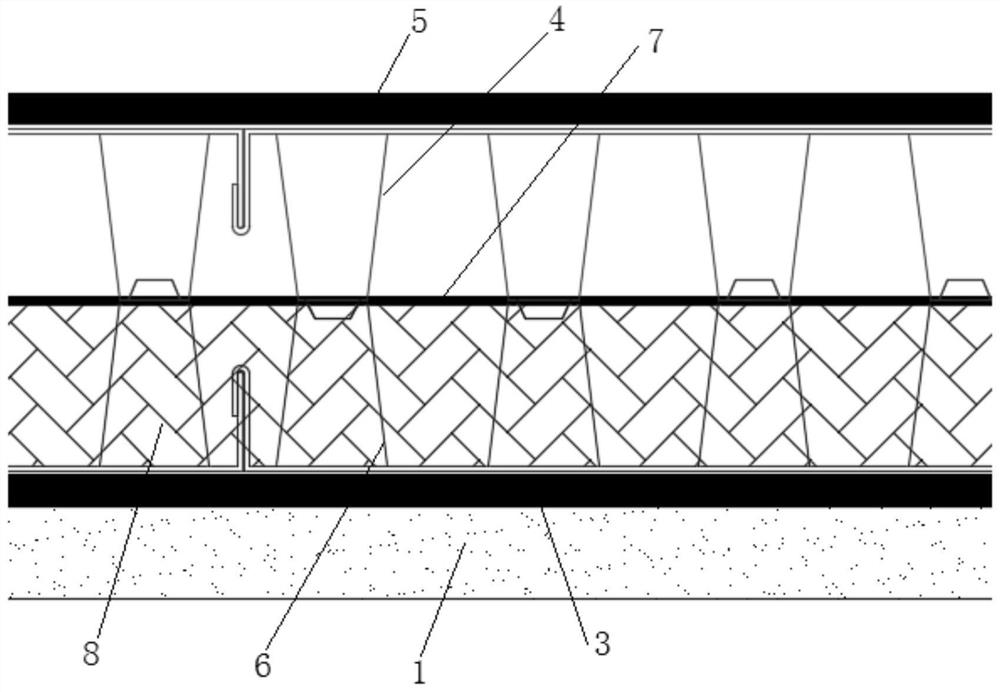

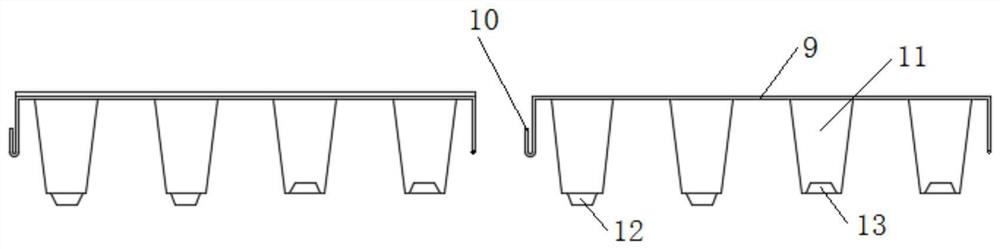

[0036] Such as figure 1 , 2 As shown, an assembleable multifunctional roof structure includes a load-bearing wall 1 and parapets 2 located at both ends of the load-bearing wall. On the outer side of the load-bearing wall 1, a lower layer of double-sided self-adhesive waterproof membrane 3 is laid. The outer side of the self-adhesive waterproof membrane 3 is laid with a front buckle prefabricated roof module 4 , and the outer side of the front buckle prefabricated roof module 4 is laid with an upper layer of heat-reflective waterproof membrane 5 .

[0037] Between the lower double-sided self-adhesive waterproof membrane 3 and the prefabricated roof module 4, a reversed prefabricated roof module 6 is laid.

[0038] A heat reflective film 7 is laid between the above-mentioned prefabricated roof module 4 and the reversed prefabricated roof module 6 .

[0039] The voids of the front buckle prefabricated roof module 4 and the reverse buckle prefabricated roof module 6 are filled w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap