Micro-lens array ultra-precision machining error evaluation method and system

A micro-lens array, ultra-precision machining technology, applied in the directions of geometric characteristics/aberration measurement, optics, measuring devices, etc., can solve the limitations of micro-lens array quality assessment. The surface roughness, position error and shape error of a single lens lack effective evaluation. methods and other issues to achieve the effect of reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

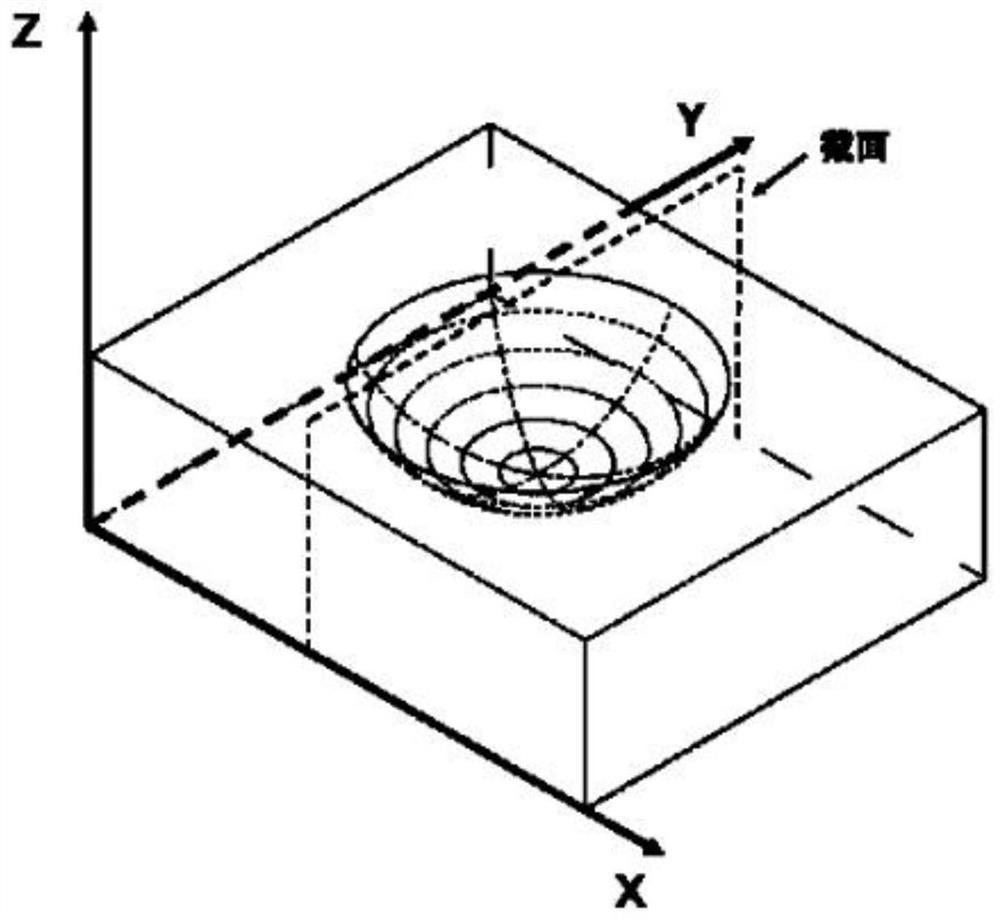

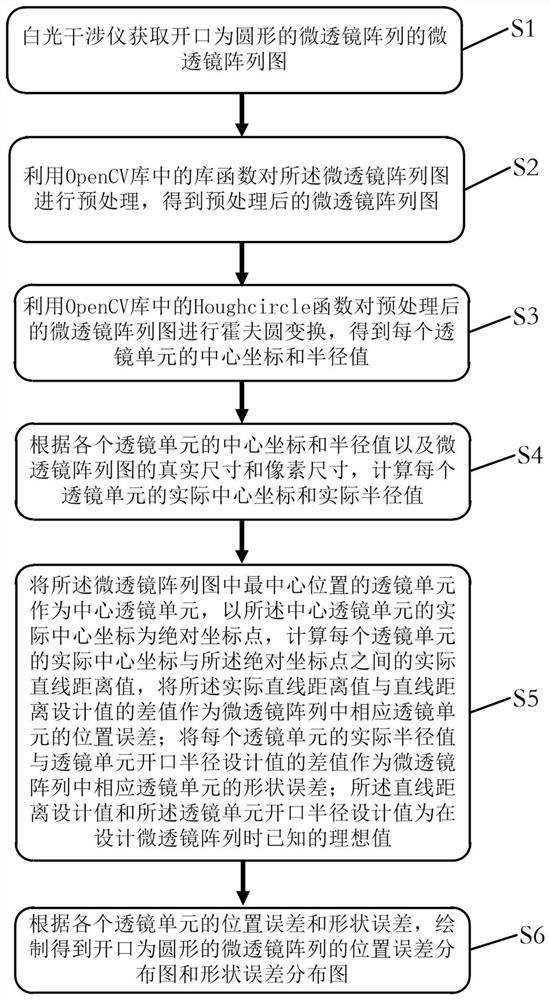

[0085] like image 3 As shown, a microlens array ultra-precision machining accuracy evaluation method, the method is suitable for microlens arrays with circular openings, the method specifically includes the following steps:

[0086] Step S1, the white light interferometer obtains the microlens array diagram of the microlens array with a circular opening, the microlens array diagram is as follows Figure 4 shown.

[0087] Step S2, using library functions in the OpenCV library to preprocess the microlens array image to obtain a preprocessed microlens array image. Specifically include:

[0088] Step S2.1, call the OpenCV library in Python, utilize the library function in the OpenCV library to read the microlens array diagram, and carry out the following preprocessing to the microlens array diagram:

[0089] Step S2.2, using a median filter method to denoise the microlens array image to obtain a denoised microlens array image. Since the noise in the microlens array image will...

Embodiment 2

[0113] like Figure 8 As shown, this embodiment proposes a method for evaluating the ultra-precision machining accuracy of microlens arrays. This method is applicable to microlens arrays with hexagonal openings, and microlens arrays with rectangular, square and other quadrilateral openings. (principle and steps are basically the same as the hexagonal microlens array, except that the quadrilateral already has a rectangular outline, and there is no need to determine the rectangular outline like a hexagon), the method specifically includes the following steps:

[0114] Step T1, the white light interferometer acquires a microlens array image of a hexagonal microlens array.

[0115] Step T2, using library functions in the OpenCV library to preprocess the microlens array image to obtain a preprocessed microlens array image. Specifically include:

[0116] Step T2.1, call the OpenCV library in Python, and utilize the library function in the OpenCV library to carry out the following ...

Embodiment 3

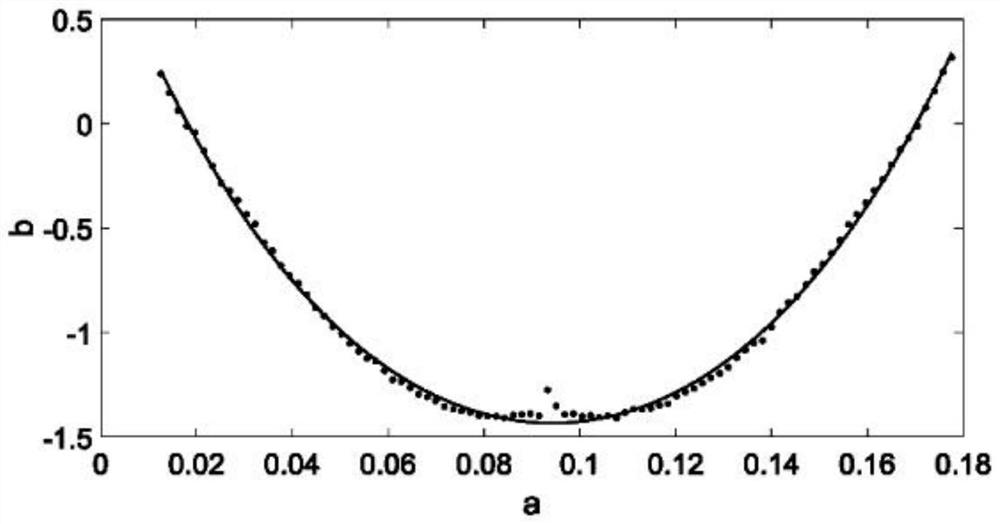

[0144] In this embodiment, aiming at the evaluation method of microlens array ultra-precision machining error, a method for evaluating the spherical radius error of microlens array is proposed, which specifically includes the following steps:

[0145] (1) The white light interferometer acquires the three-dimensional data of a single lens unit.

[0146] (2) Transform the sphere equation into a linear equation in matrix product format, use the three-dimensional data to fit the converted linear equation to obtain a linear equation with a high degree of fitting, and calculate the actual radius of the fitted sphere value.

[0147] Wherein, the described sphere equation is converted into a linear equation in matrix product format, specifically including:

[0148] The spatial spherical equation (x-a) 2 +(y-b) 2 +(z-c) 2 =R 2 into the following form:

[0149] -2xa-2yb-2zc+1*(a 2 +b 2 +c 2 -R 2 )=-x 2 -y 2 -z 2

[0150] setting A 1 =-2x,A 2 =-2y,A 3 =-2z,A 4 =a 2 +b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com