High-sensitivity small-blind-area ultrasonic detection method for bearing ring

A high-sensitivity, bearing ring technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc., can solve the problems of large blind spots and low sensitivity, and achieve accurate detection And locate, ensure the quality of inspection, improve the effect of defect control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

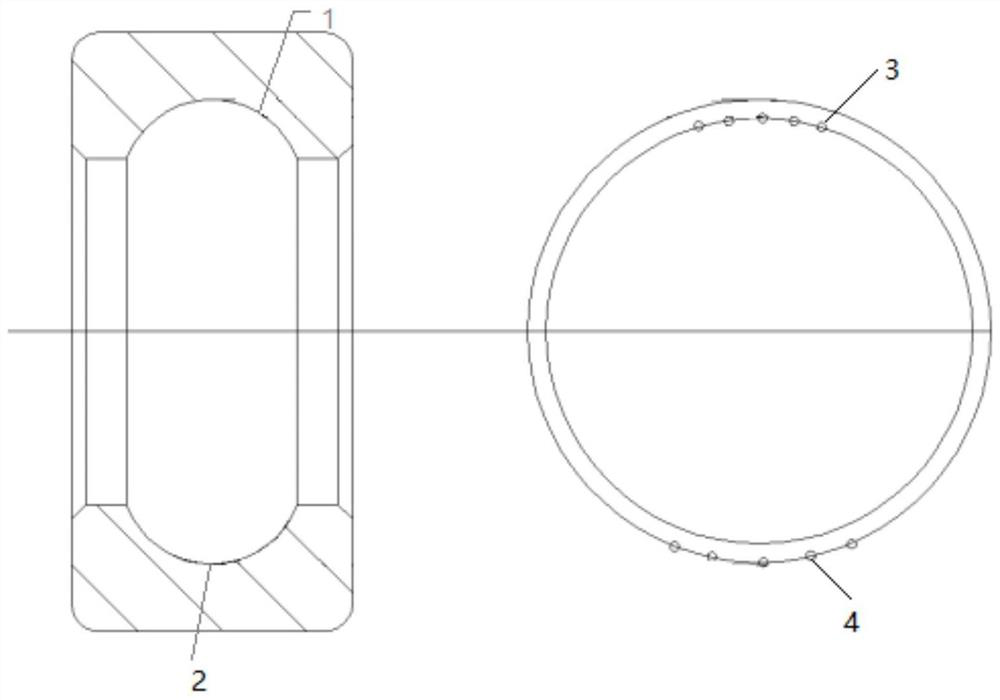

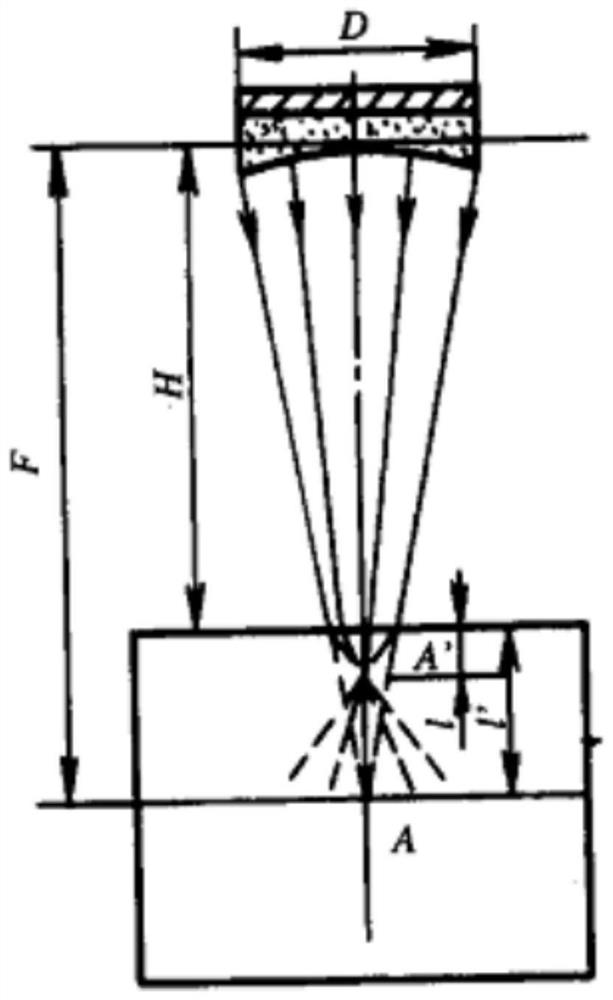

[0027] Specific implementation mode 1: In this implementation mode, the high-sensitivity small blind area ultrasonic detection method of the bearing ring is realized according to the following steps:

[0028] 1. Sample preparation:

[0029] Flat-bottomed hole comparison sample: The material of the flat-bottomed hole comparison sample is 8Cr4Mo4V, which is consistent with the ferrule to be tested, and the processing state and size are the same. Processing size: 6 pieces in total, the hole diameter is Φ0.4mm, and the diameter is 50.8mm. The buried depths are 1.6mm, 3.2mm, 6.4mm, 12.7mm, 25.4mm and 38.1mm, and the thicknesses are 8.0mm, 9.6mm, 12.8mm, 19.1mm, 31.8mm and 44.5mm;

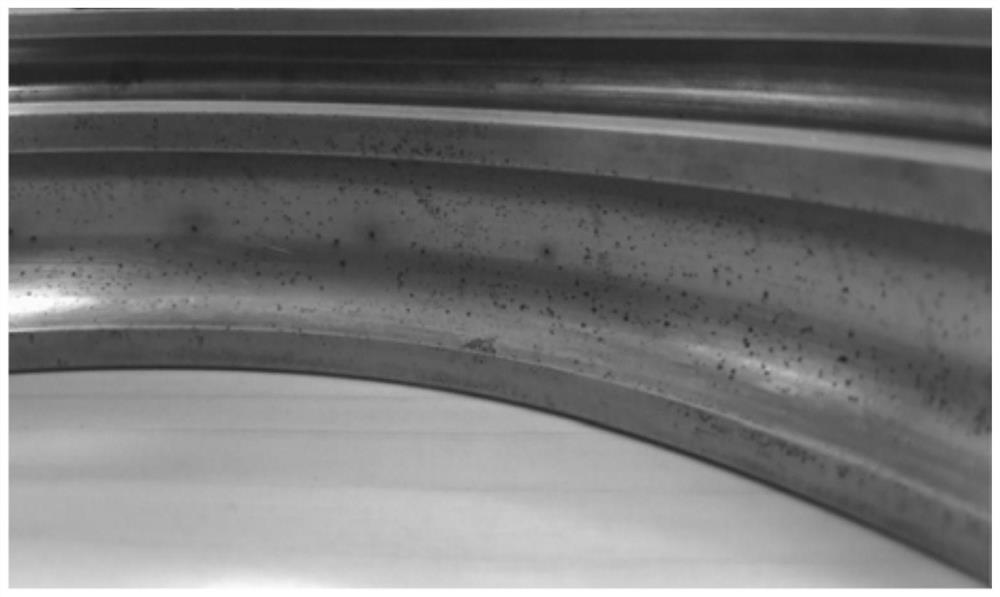

[0030] Raceway flat-bottomed hole sample: take the ferrule to be inspected and make flat-bottomed holes near the surface with different buried depths. Each hole is spaced at 5mm, a total of two groups, respectively located at the center of the arc bottom of the ferrule to be inspected and 1 / 2 the distan...

specific Embodiment approach 2

[0037] Embodiment 2: This embodiment is different from Embodiment 1 in that the burrs caused by the flat-bottomed hole comparison sample in step 1 are removed during processing, and the upper and lower edges are rounded. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0038] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that the water immersion ultrasonic equipment described in step 3 adopts the Scan Master disk ring ultrasonic water immersion detection system, model LS-500, with C-scan imaging function, parameters : The detection sensitivity is Ф0.4mm-10dB equivalent flat bottom hole, and the pulse repetition frequency is 600Hz. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com