Vibroflotation construction operator guiding method and system

A technology of operators and working methods, applied in the field of civil engineering, can solve the problems of irregular construction and the ineffective control of the vibro-construction process, and achieve the effect of ensuring integrity and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

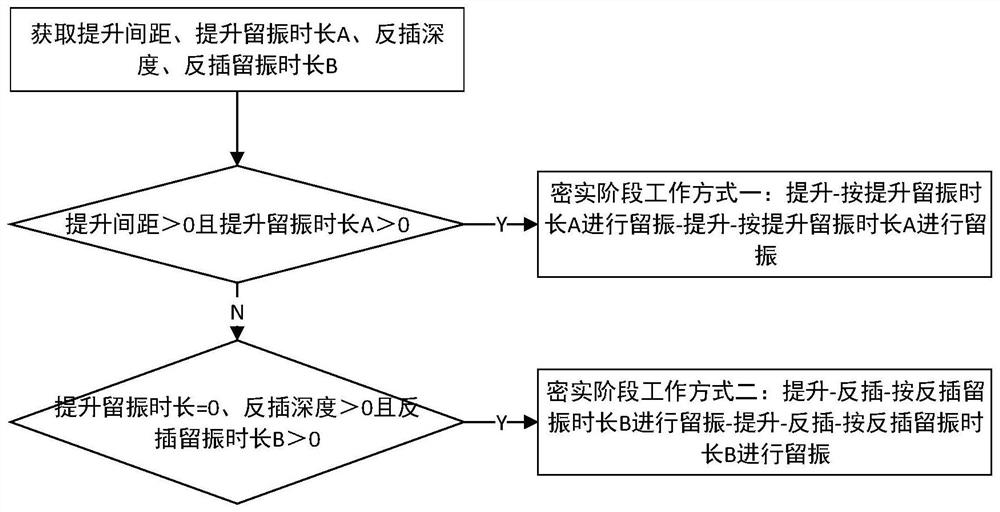

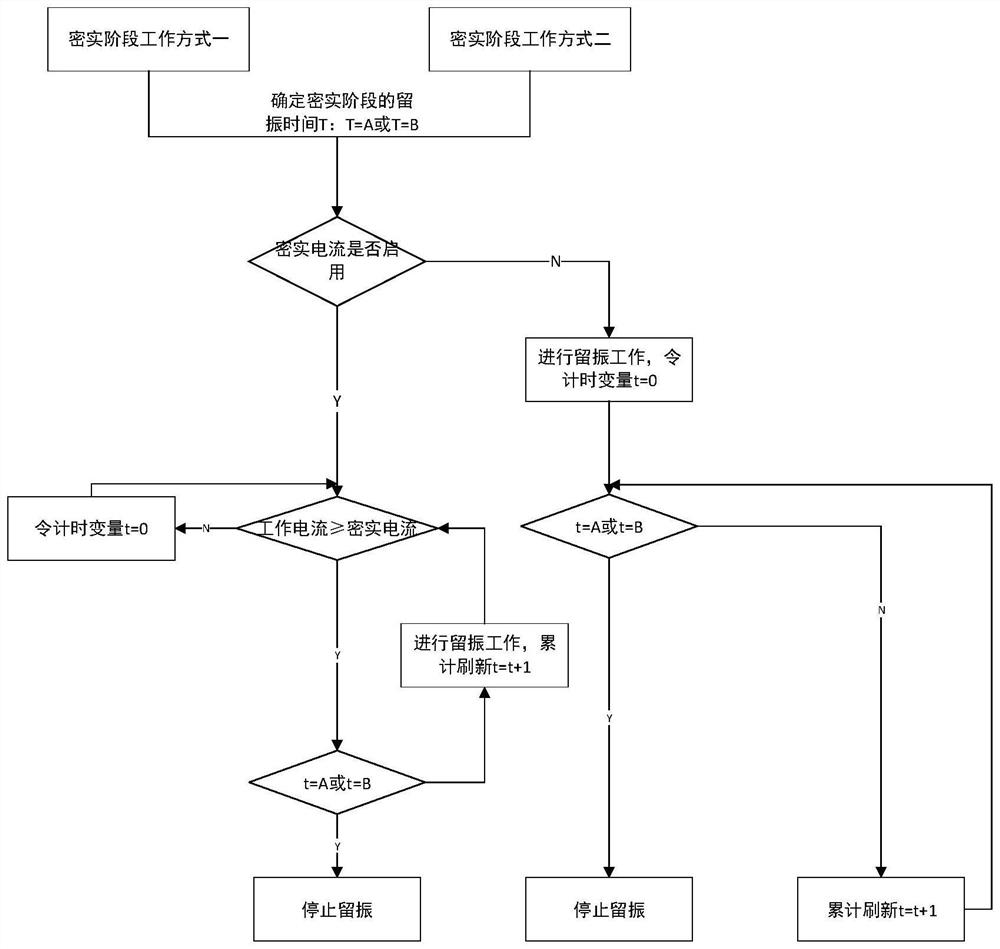

[0074] A vibro-construction operator guidance method specifically includes the following steps:

[0075] S1. Obtain the setting parameters sent by the human-computer interaction interface, the setting parameters include the lifting distance, the lifting vibration duration A, the reverse insertion depth, and the reverse insertion vibration duration B;

[0076] S2. Judgment is made according to the lifting distance, the lifting vibration duration A, the reverse insertion depth, and the reverse insertion vibration duration B, and different control instructions are issued to make the vibrating device perform vibrating operations in different working modes during the compacting stage. Specifically include the following situations:

[0077] When the lifting distance > 0 and the lifting vibration retention time > 0, the first control instruction is issued to make the vibrator perform vibrating operation in the compacting stage in working mode 1. The working mode 1 is: lifting - accor...

Embodiment 2

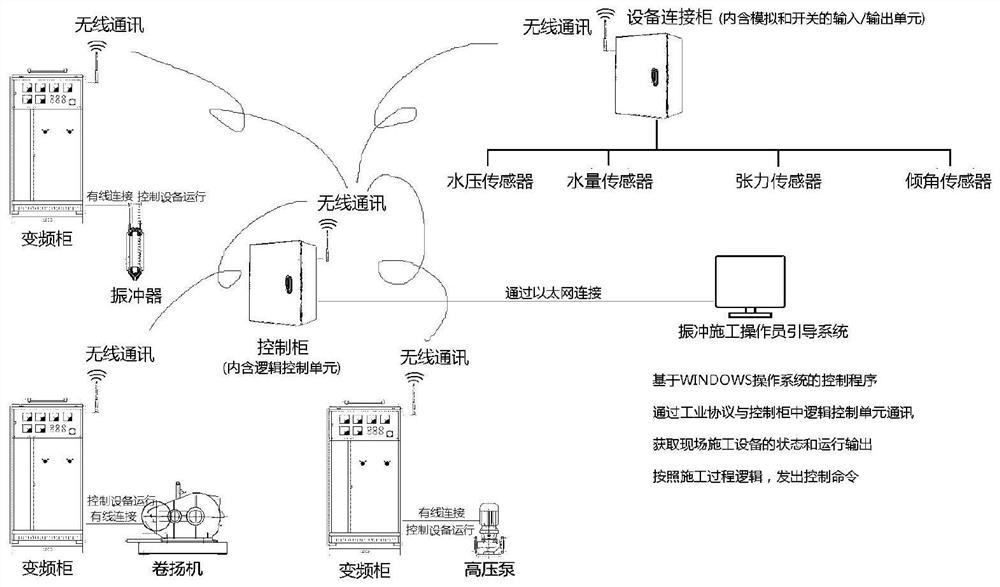

[0111] The purpose of this embodiment is to provide a vibroconstruction operator guidance system, including:

[0112] Acquisition parameter module: used to obtain the setting parameters sent by the human-computer interaction interface, the setting parameters include the lifting distance, the lifting vibration duration A, the reverse insertion depth, and the reverse insertion vibration duration B;

[0113] Determine the working mode module: used to make judgments based on the lifting distance, the lifting vibration duration A, the reverse insertion depth, and the reverse insertion vibration duration B, and issue different control instructions to make the vibro impactor work in different ways during the compaction stage Perform vibrating operations, specifically including the following situations:

[0114] When the lifting distance and the lifting vibration duration > 0, the first control command is issued to make the vibrator perform the vibrating operation in the compacting st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com