Efficient heat dissipation system of high-power laser product

A heat dissipation system, high-power technology, applied in the direction of modification by conduction heat transfer, cooling/ventilation/heating modification, modification with gaseous coolant, etc., can solve the problem of difficult to deal with the heat of high-power lasers, and achieve heat dissipation efficiency. Low, improved life and reliability, effect of improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

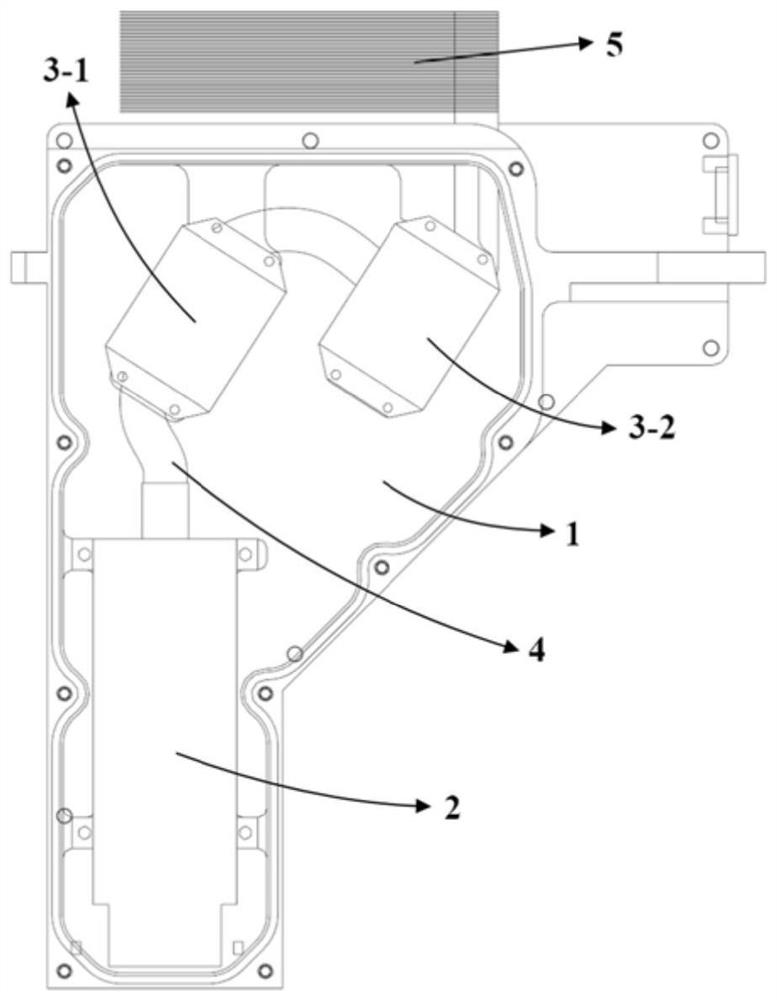

[0021] A high-efficiency heat dissipation system for high-power laser products, suitable for heat dissipation of high-power products in confined and small spaces, mainly including heat transfer module, heat dissipation module, fan module, oscillation stage, amplification stage 1, amplification stage 2, laser The radiator shell, the heat transfer module is set in the shell of the laser radiator, respectively connected to the oscillation stage and the amplifier stage 1, and the amplifier stage 1 and the amplifier stage 2 are connected. The module is arranged outside the shell of the laser radiator, and performs fluid-solid coupling heat exchange with the heat dissipation module to cool down the heat dissipation module.

[0022] Wherein, the laser radiator is in a discontinuous working state, and the oscillation stage, the first amplification stage, and the second amplification stage generate heat under the working state, and the heat transfer module is connected with the oscillat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com