Centrifugal spray dryer for hydrolyzing wheat protein powder

A technology of centrifugal spray drying and wheat protein powder, which is applied in the direction of spray evaporation, evaporator accessories, etc., can solve the problems of wheat flour removal, affecting the preparation of wheat protein powder, etc., and achieve the effect of stable drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

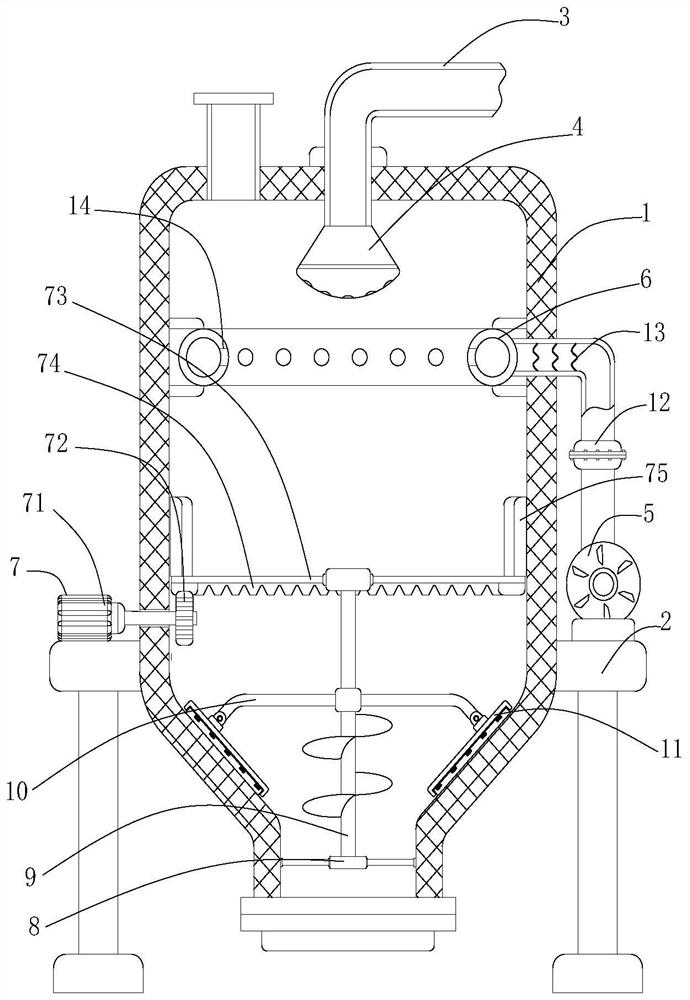

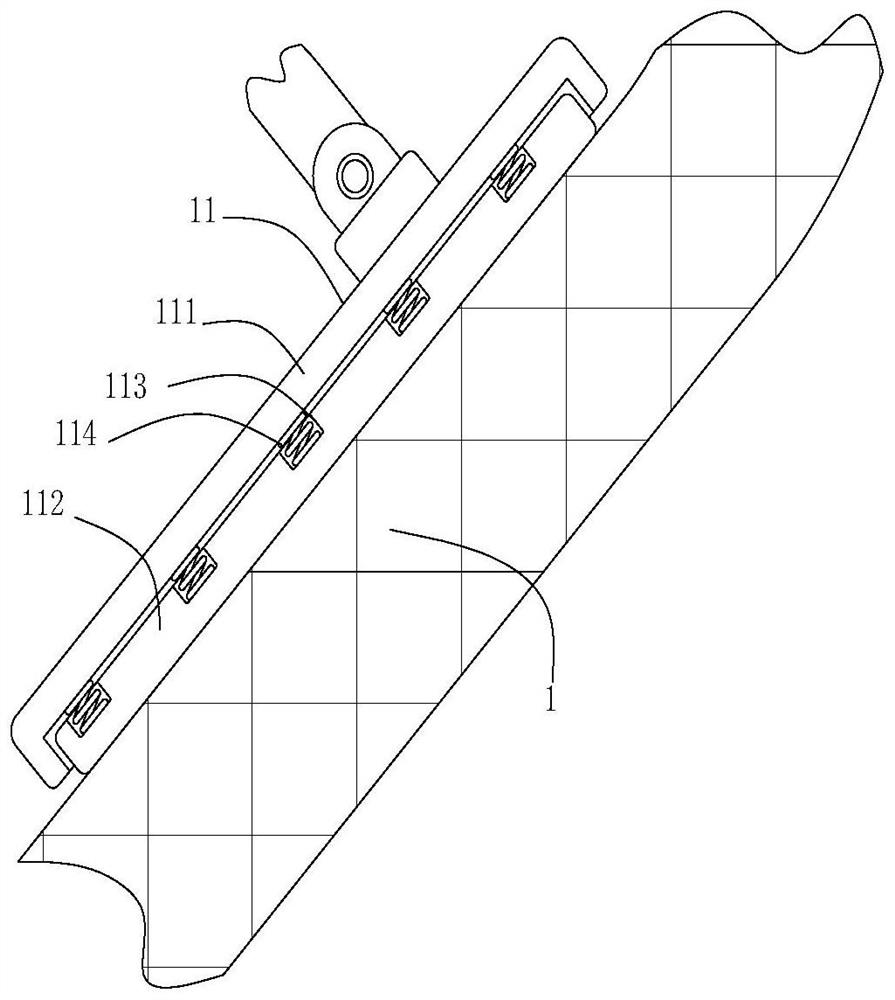

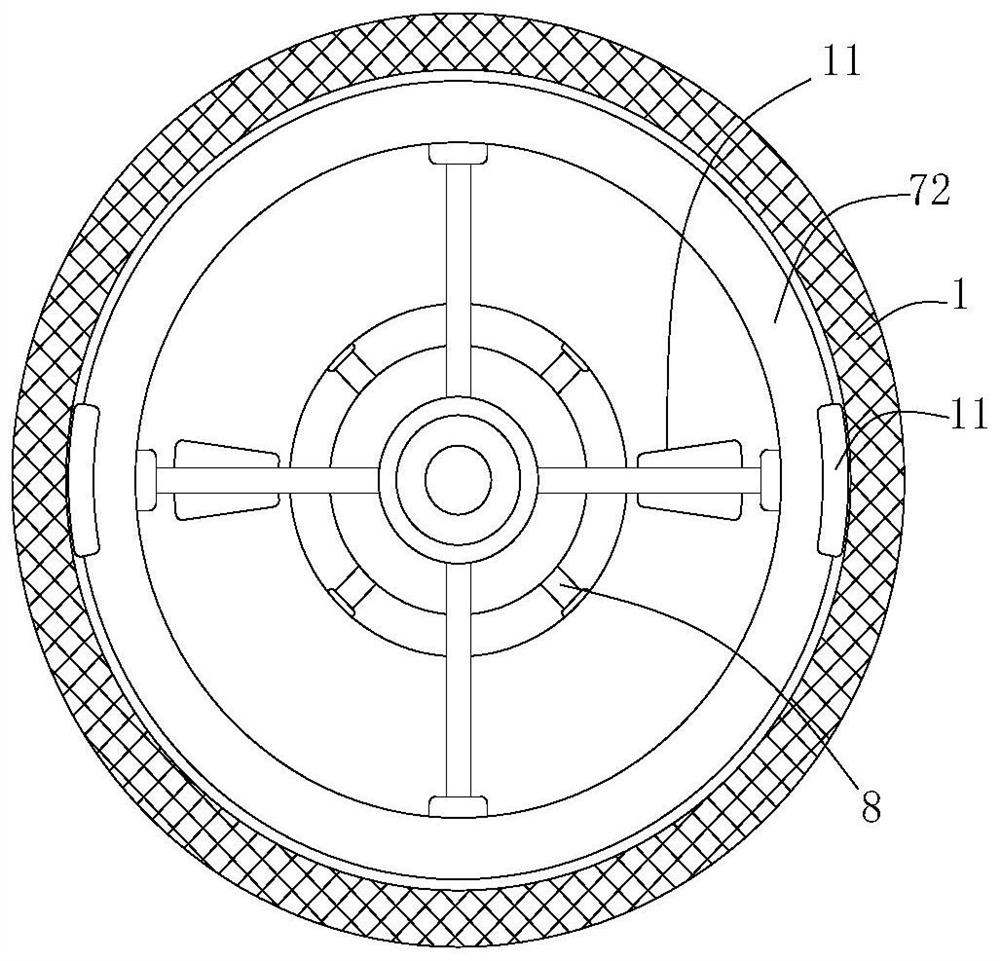

[0011] Such as Figure 1-3 As shown, Embodiment 1 of the present invention provides a kind of centrifugal spray dryer for hydrolyzing wheat gluten powder, comprises housing 1, and the bottom of housing 1 is funnel-shaped, and housing 1 is provided with support ring 2, and support ring 2 Located near the funnel-shaped outer wall of the shell 1, the inner wall of the support ring 2 is welded to the shell 1, the bottom of the support ring 2 is provided with support legs, and the top of the shell 1 is communicated with a feed pipe 3 extending to the inside of the shell 1. One end of the feed pipe 3 located inside the shell 1 is provided with a spray head 4, one side of the top of the support ring 2 is provided with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap