Full-automatic jacking and assembling all-in-one machine for notebook computer keyboard

A notebook computer, fully automatic technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of inconvenient picking and placing of the keyboard, insufficient accuracy of placing and picking, and affecting the yield rate of the keyboard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

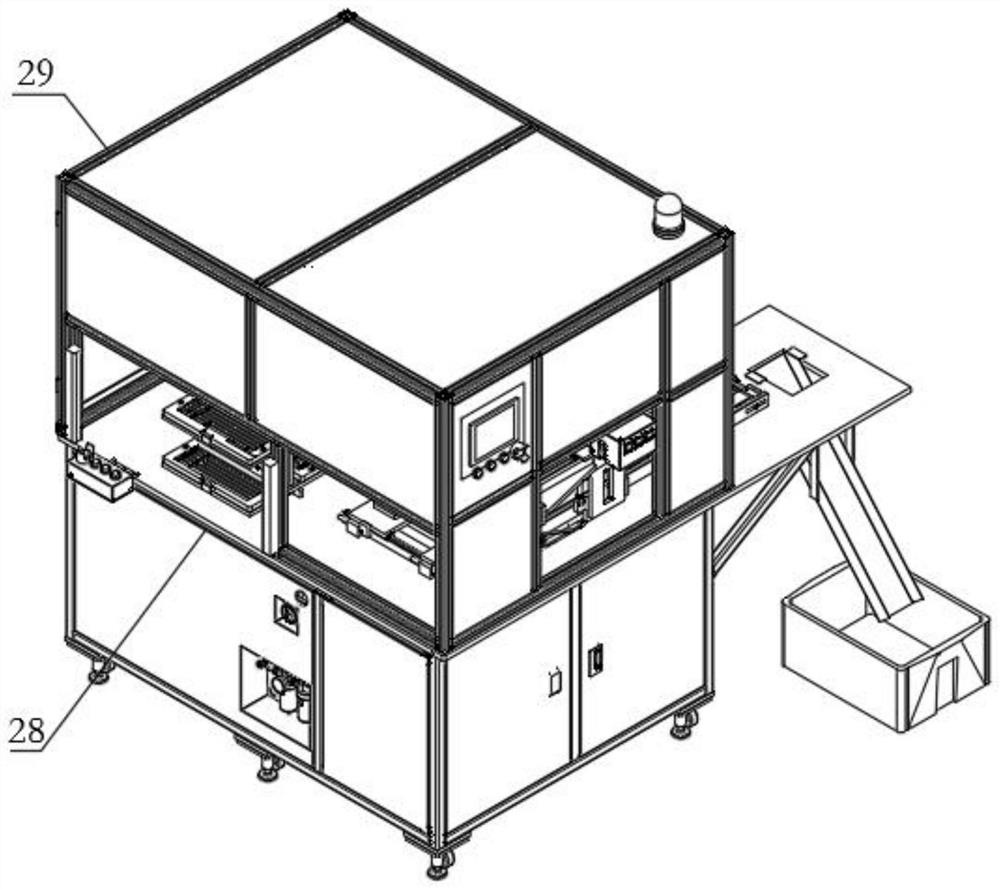

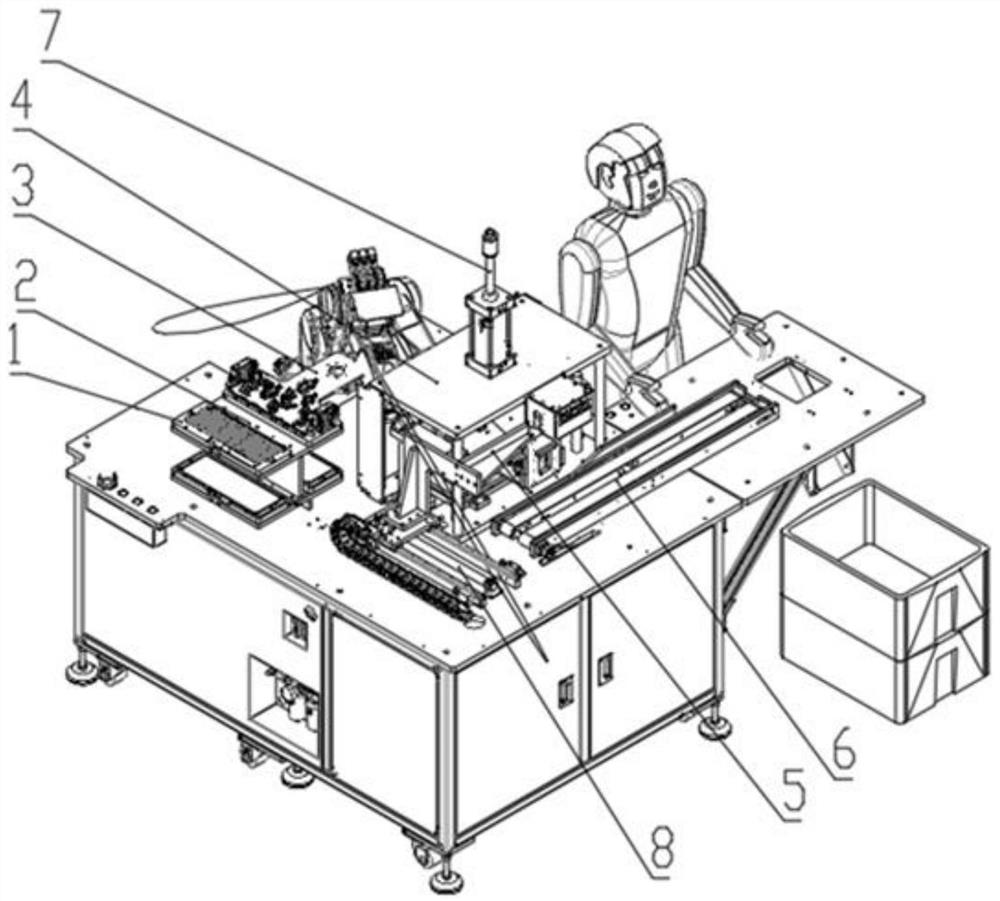

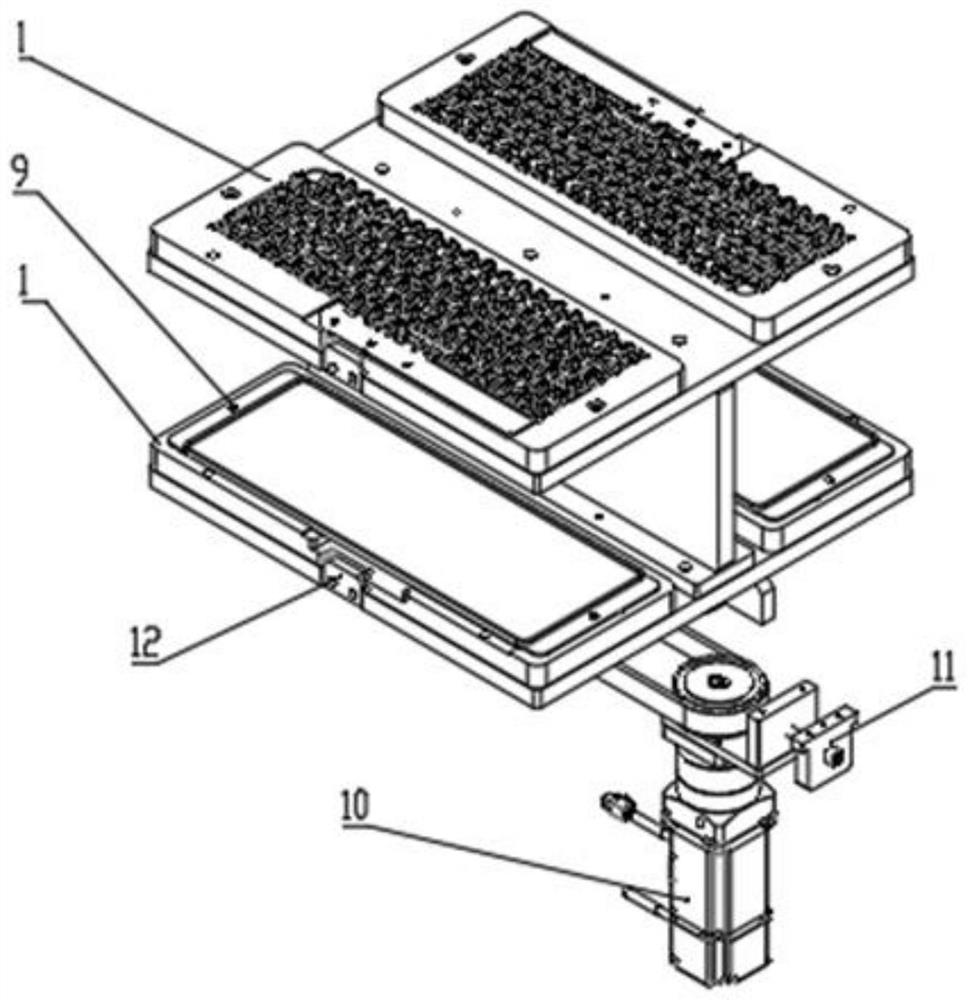

[0030] The present invention provides a fully automatic top press assembly for laptop keyboard, such as Figure 1 - Figure 9 As shown, the machining platform 28 is provided, and the outer side of the machining platform 28 is mounted, and the outer portion of the device is protected outside, and the top of the processing platform 28 is mounted with a rotating mechanism 2 for the keyboard and scissors. The positioning bottom mold 1 is rotated, and the rotating mechanism 2 places a keyboard and the shear plate positioning bottom mold 1, and the rotating mechanism 2 is mounted on one side of the rotation mechanism 2, which is used to carry out the tether, the central midth of the processing platform 28 is mounted. The top pressure mechanism 4 is used to assemble the product, and a transverse shift mechanism 5 is mounted on one side of the top pressure mechanism 4 for transmitting the product to the conveying flow channel 6, the transverse mechanism 5 A linear motor 8 is mounted at the ...

Embodiment 2

[0038] In order to further use the assembly and top out of the different products, the top pressure mechanism 4 includes a bracket, a top pressure cylinder 7 is mounted on the top of the stent, and the upper and lower sides of the stent are respectively mounted, and the upper cylinder 23 and the lower cylinder 22 are mounted, and the upper cylinder 23 is vertical direction. Set, the lower cylinder 22 is a lateral arrangement, and a safety grating 24 is mounted on one side of the stent, and the safety grating 24 facilitates whether the pickup mechanism 3 is in the top pressure mechanism 4, and the top pressure mechanism 4 determines whether or not the lower pressure is reduced. Whether there is anything other than other things in the pressing mechanism 4, there is a distance sensor 20 in the upper portion of the stent, and the position of the product placed in the bracket is judged, and the corresponding lift is made by the upper cylinder 23 and the down-cylinder 22. Transfer to ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com