Ultrasonic Lamb wave logging well wall acoustic interface reverse time migration imaging method

A reverse time migration imaging and ultrasonic technology, which is used in earth-moving drilling, construction, etc., can solve the problems such as the inability to obtain the accurate position of the acoustic interface of the borehole wall, the failure of the A0 reflected wave to converge, and the influence of the amplitude of the A0 reflected wave.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

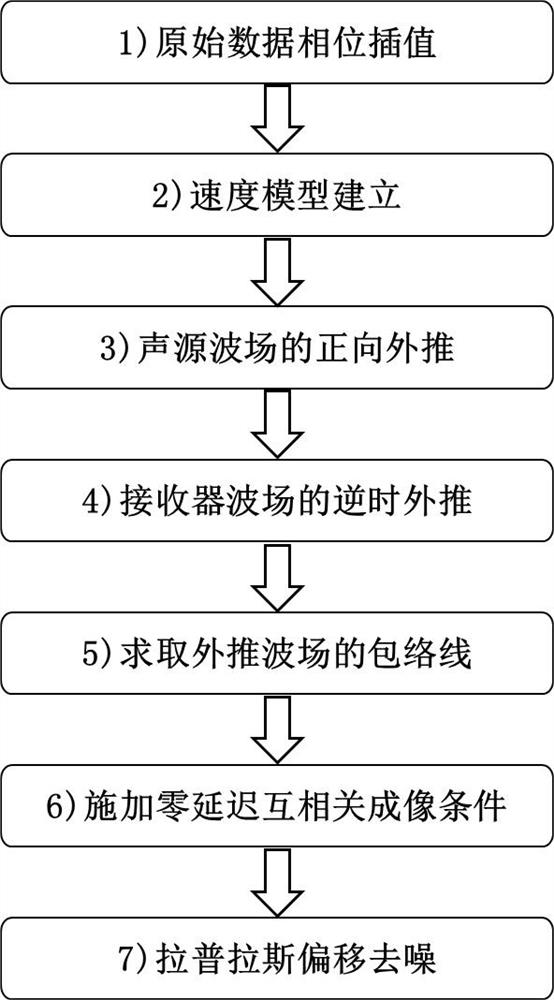

[0061] In this example, if figure 1 As shown, a reverse time migration imaging method of acoustic interface of ultrasonic Lamb wave logging borehole wall includes the following steps:

[0062] Step1: Raw data input and A0 mode wave phase interpolation:

[0063] Input the raw data of ultrasonic Lamb wave logging and the velocity of fluid in the well, casing thickness, casing longitudinal wave and shear wave velocity and center frequency parameters, and calculate the theoretical dispersion curve of A0 mode wave. Based on the phase velocity of A0 mode wave, the phase shift is adopted method to obtain the waveform of a certain receiver's waveform traveling forward or backward for a certain distance:

[0064] g(t)=∫F(w)H(w)e -jwt dw

[0065]

[0066] Among them, g(t) is the propagation distance x 0 After the waveform, F(w) is the spectrum of the original A0 mode wave signal, w is the angular frequency, e is the natural logarithm, H(w) is the propagation matrix, and k is the ...

Embodiment 2

[0093] This embodiment is an implementation case of simulating ultrasonic Lamb wave logging data, and the specific trial calculation process is as follows:

[0094] (1) Read in the ultrasonic Lamb wave logging simulated wave field record (SimulatedLamb.dat), and input the fluid velocity and density in the well, casing density, casing P-wave velocity, casing S-wave velocity, cement density, cement P-wave velocity, and cement S-wave Velocity, formation density, formation compressional wave velocity, formation shear wave velocity.

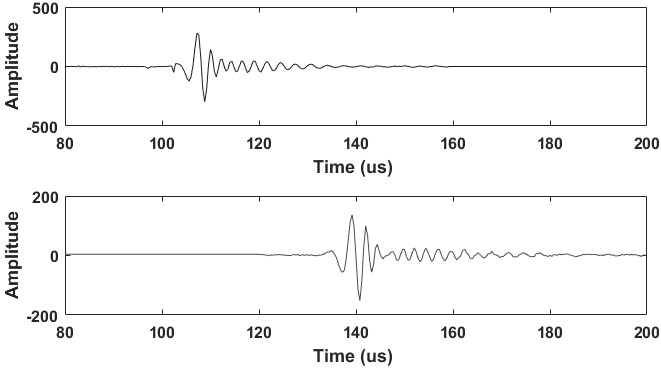

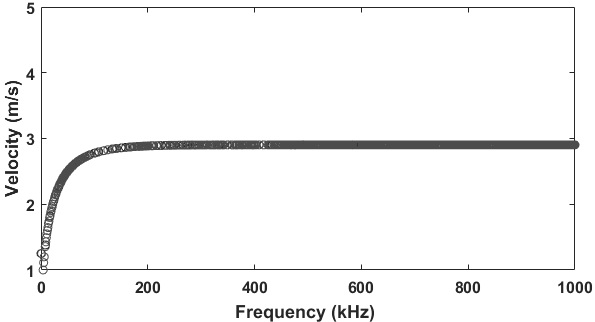

[0095] (2) Calculate the theoretical dispersion curve of the A0 mode wave, perform phase interpolation on the original ultrasonic Lamb wave data, and expand the original two detector data into array waveform data.

[0096] (3) Set the grid size and model size, and establish the initial velocity model of the target area.

[0097] (4) Based on the two-dimensional high-order staggered grid finite difference and non-split perfect matching layer, the ultr...

Embodiment 3

[0102] This embodiment is an implementation case of the actual measurement of ultrasonic Lamb wave calibration well data, and the specific trial calculation process is as follows:

[0103](1) Read in the simulated wave field records of ultrasonic Lamb wave logging, and input the fluid velocity and density in the well, casing density, casing P-wave velocity, casing S-wave velocity, cement density, cement P-wave velocity, cement S-wave velocity, formation density, Formation compressional wave velocity, formation shear wave velocity.

[0104] (2) Calculate the theoretical dispersion curve of the A0 mode wave, perform phase interpolation on the original ultrasonic Lamb wave data, and expand the original two detector data into array waveform data.

[0105] (3) Set the grid size and model size, and establish the initial velocity model of the target area.

[0106] (4) Based on the two-dimensional high-order staggered grid finite difference and non-split perfect matching layer, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com