Lateral steam admission condenser tube bundle

A condenser and steam inlet technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the problem of increased investment in side steam inlet condensers, unsatisfactory heat transfer coefficient, and excessive shell side flow resistance and other problems, to achieve obvious energy-saving effect, easy pipe installation, and no eddy current in the flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

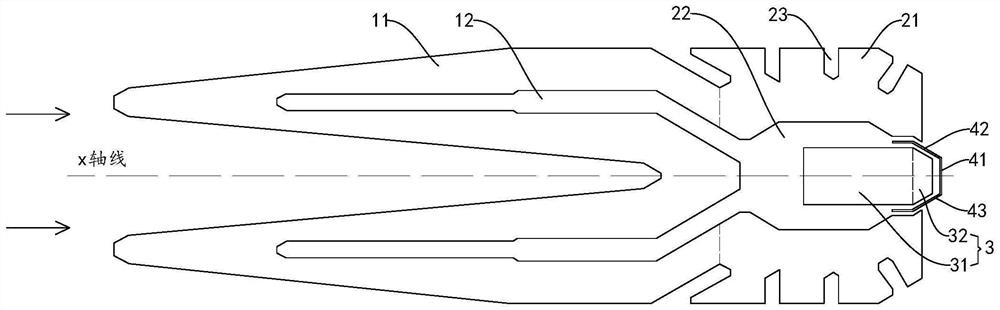

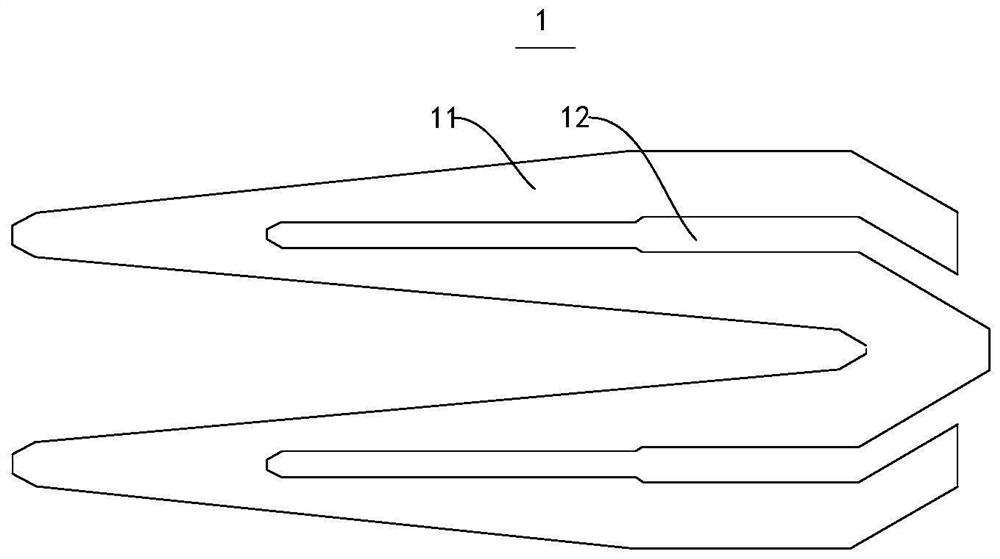

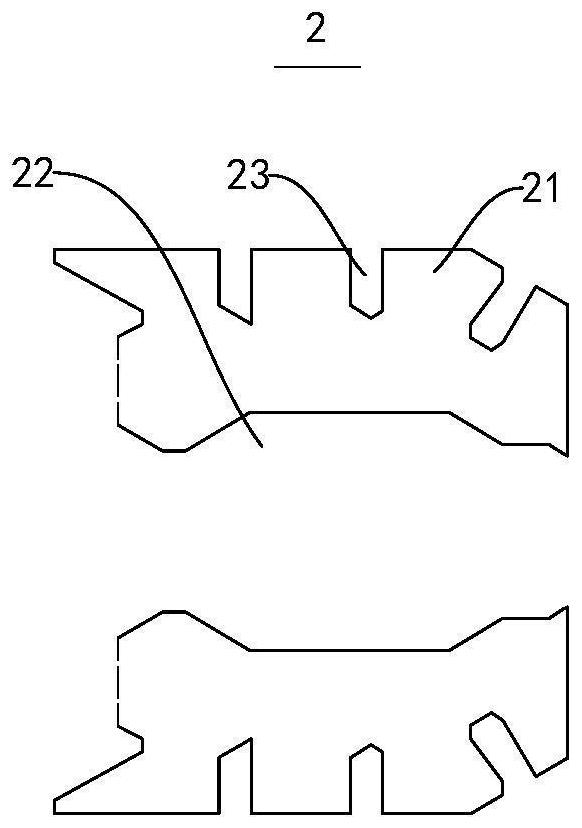

[0031] Please refer to Figure 1 to Figure 4 , this embodiment provides a side inlet condenser tube bundle, the side inlet condenser adopts side inlet, and the exhaust steam discharged from the low pressure cylinder of the steam turbine flows horizontally in the inner cavity of the condenser, this embodiment It includes a number of heat exchange tubes, and several heat exchange tubes are arranged to form the front tube bundle area 1, the rear tube bundle area 2 and the air-cooled tube bundle area 3. The heat exchange tube constitutes a specific shape, such as Figure 5 As shown, the front-end tube bundle area 1, the rear-end tube bundle area 2 and the air-cooled tube bundle area 3 are sequentially arranged in the inner cavity of the condenser along the exhaust direction of the condenser. Specifically, the tube bundle of the air-cooled tube bundle area 3 occupies the entire tube bundle The percentage of the total quantity is 5%-7%; the air-cooled tube bundle area 3 is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com