Mini-LED structure with spliced subarea cells and production process of mini-LED structure

A mini-led, production process technology, applied in the field of LED backlight, can solve the problem of inconvenient removal and replacement of mini-LED chips, and achieve the effect of reducing the probability of de-soldering, less quantity and high production level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following is attached Figure 1-9 The application is described in further detail.

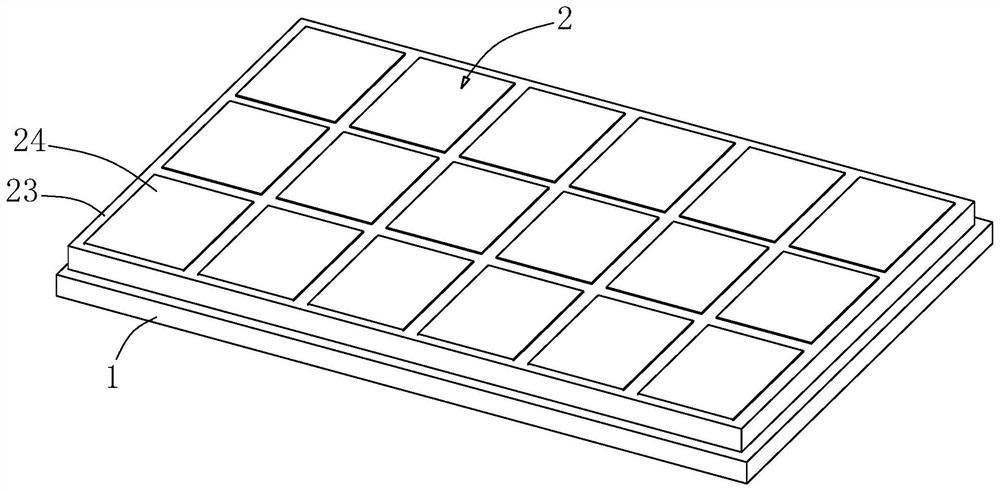

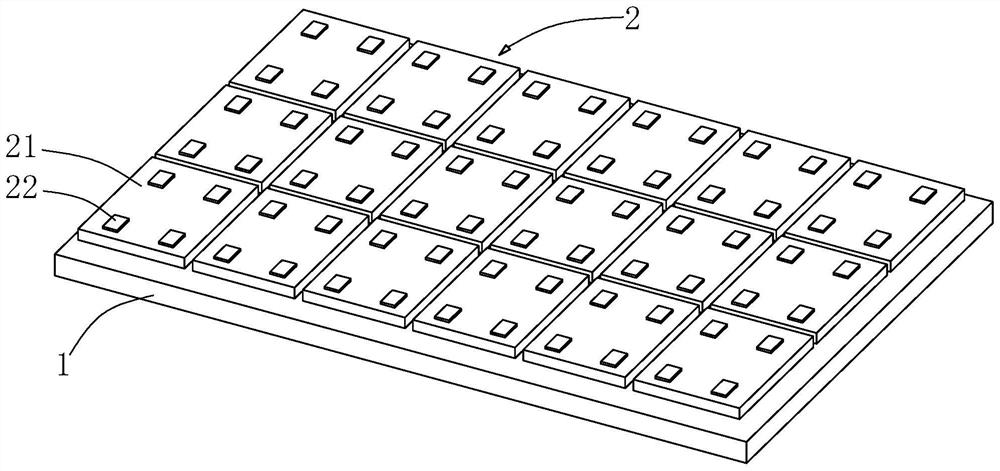

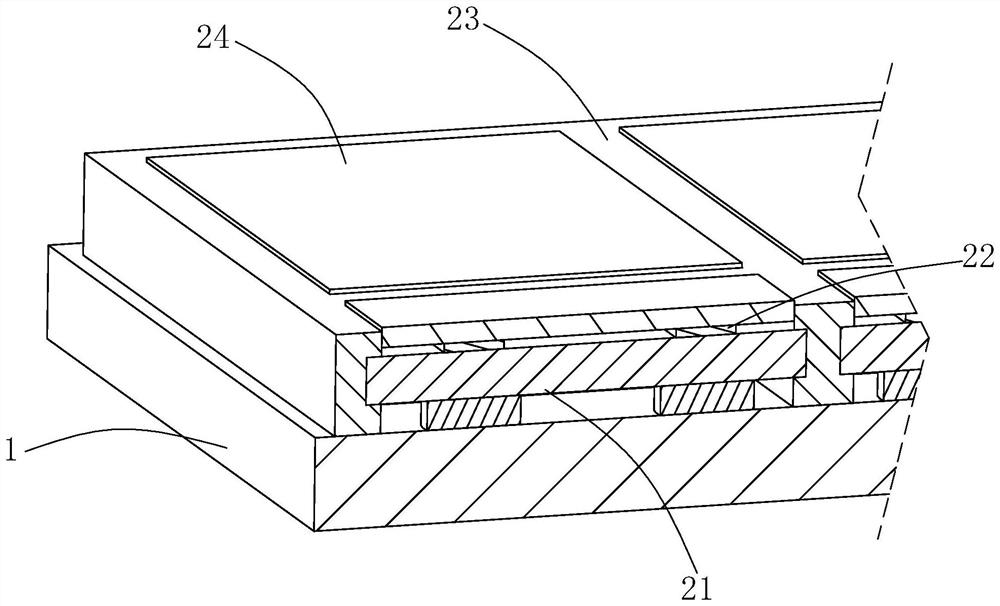

[0050] The embodiment of the present application discloses a mini-LED structure with splicing of partitioned cells. refer to figure 1 with 2 , including a PCB base carrier 1, a plurality of partition cells 2 are arranged on one surface of the PCB base carrier 1, and the partition cells 2 include a PCB partition carrier 21 electrically connected to the surface of the PCB base carrier 1 and a plurality of The mini-LED chips 22, a plurality of mini-LED chips 22 are fixedly connected to a surface of the PCB partition carrier 21 away from the PCB base carrier 1 and the mini-LED chips 22 are electrically connected to the PCB partition carrier 21. If it is found that the mini-LED chip 22 in a certain partition cell 2 cannot work normally, the worker can desolder the PCB partition carrier board 21 of the partition cell 2 and replace it with a new partition cell 2 . The number of mini-LED...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com