Hot rolled steel coil end face quality detection device

A detection device and technology for hot-rolled steel coils, which are used in length measuring devices, metal rolling, metal rolling, etc., can solve the problem of inability to remove oxide layers and impurities on the end face of steel coils, insufficient photographing data, and inability to adjust sampling pressure, etc. problems, to achieve the effect of ensuring firmness, quick disassembly, and rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

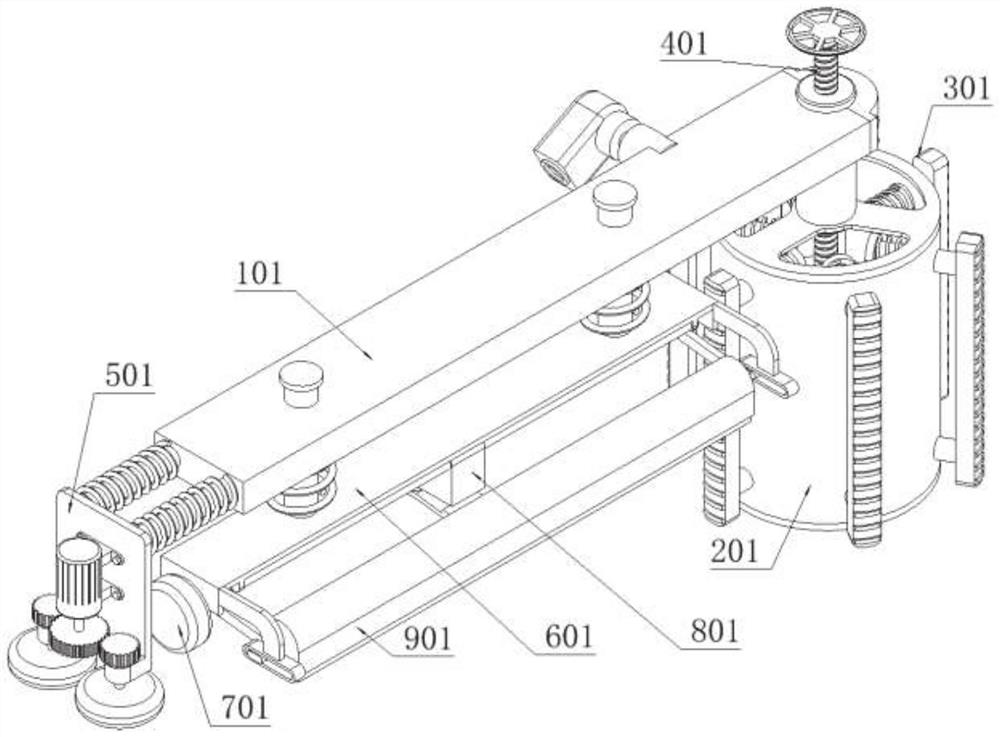

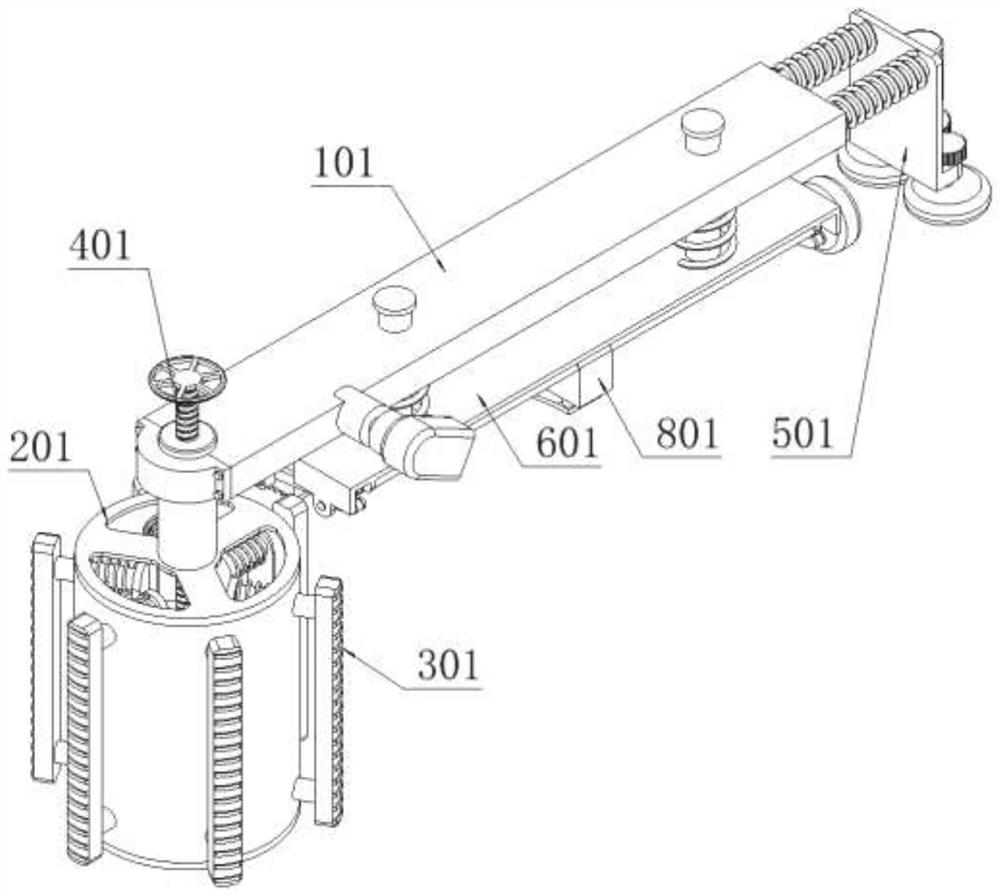

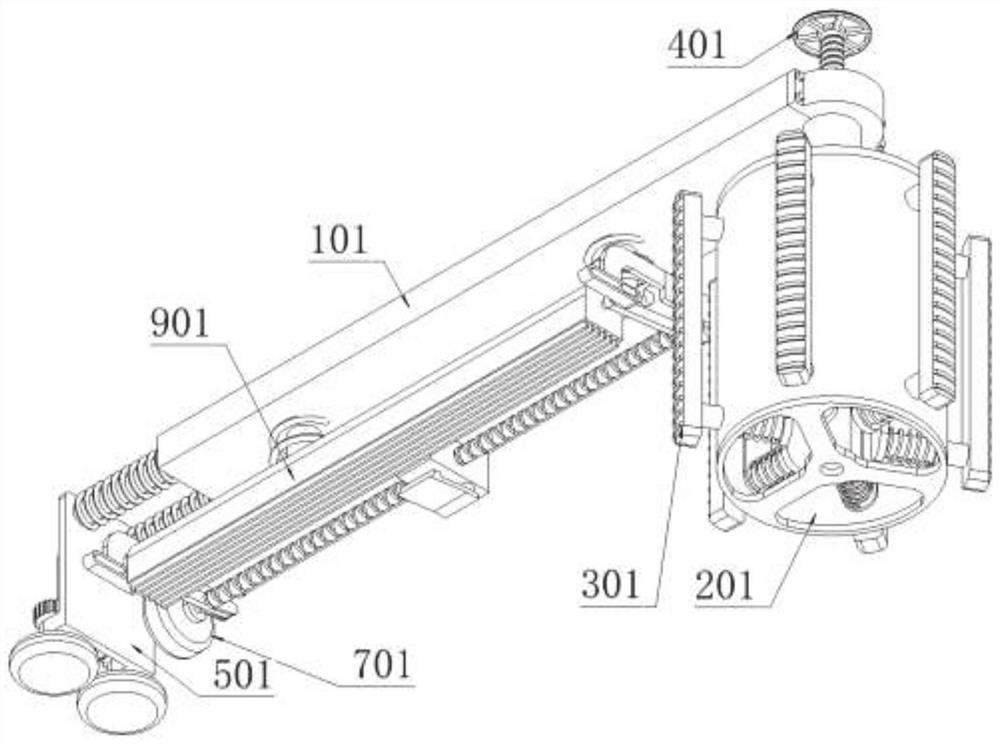

[0079] Append figure 1 Attachment Figure 12 Looking:

[0080] The present invention provides a hot-rolled steel roll end surface mass detecting device including a support device 1; a support device 1, a support device 1 rotating is attached to the mounting portion 2; there is six positioning portions 3 on the mounting portion 2; mounting portion 2 The upper thread rotation is connected to the positioning drive structure 4; the support device 1 slides to connect the circulation drive structure 5; the support device 1 slides to connect the floating portion 6, and the floating portion 6 rotates the axis to contact the operating device 7; sample portion 8 The sample portion 8 is threaded to be connected to the operating device 7; the cleaning unit 9 is fixed to the floating portion 6.

[0081] Append Figure 4 , 8 As shown, the support device 1 includes a support frame 101, and the support frame 101 rotates axial attached to the mounting portion 2; the camera 102, the camera 102 rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com