Aluminum alloy profile machining tool and clamping mechanism thereof

A clamping mechanism and profile technology, applied in metal processing machinery parts, metal processing equipment, clamping and other directions, can solve the problems of reducing the safety performance of equipment, the danger of manual cleaning, the separation of aluminum alloy profiles from the clamping mechanism, etc. Practicality, increased fixation, increased safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

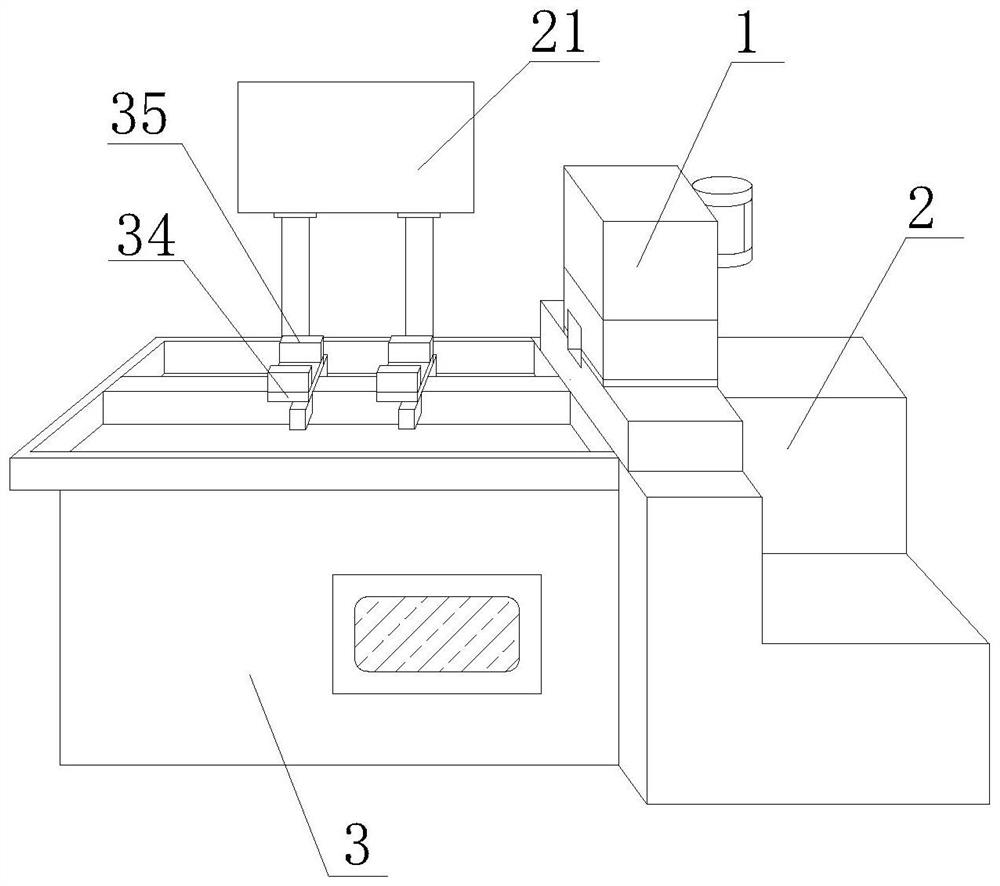

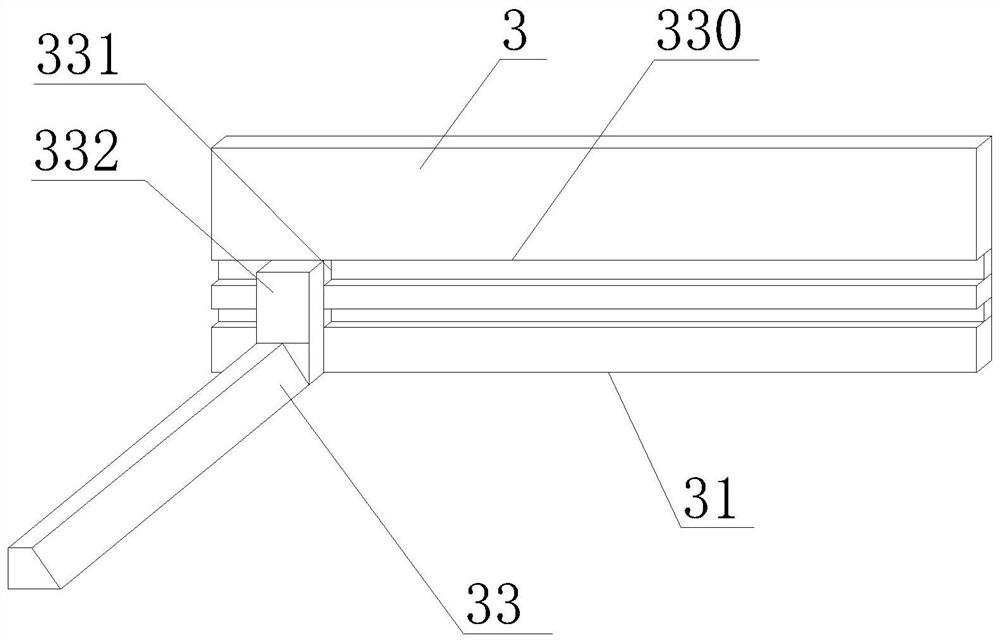

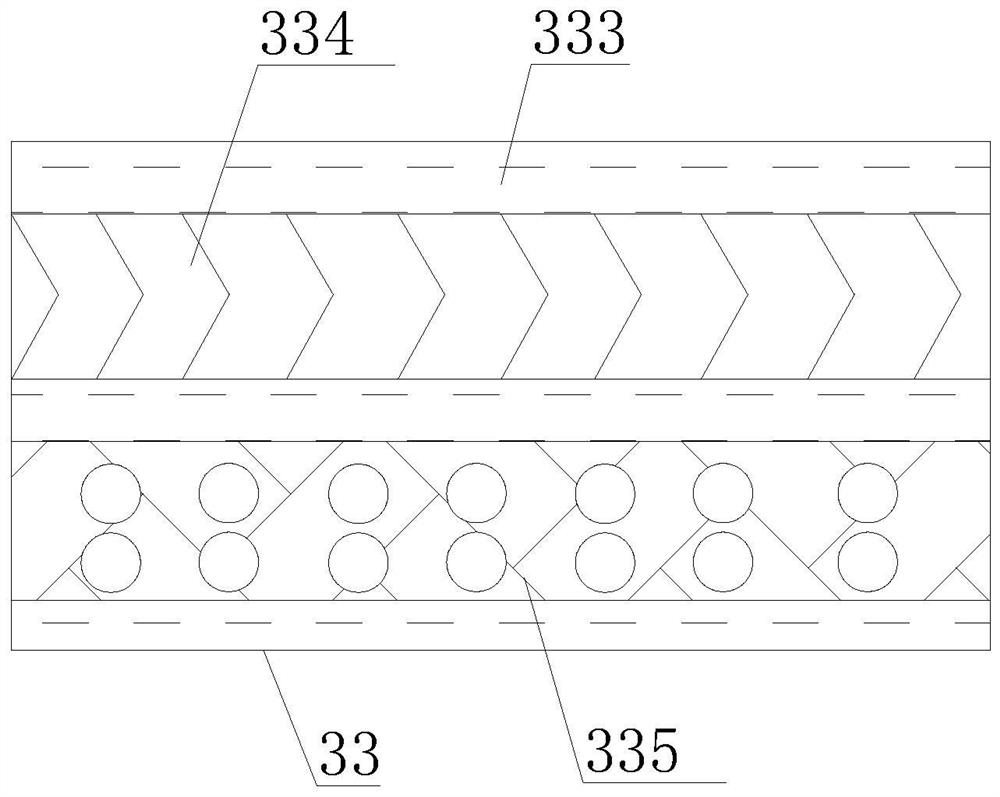

[0037] First aspect, such as Figure 1-9 As shown, the present invention provides an aluminum alloy profile processing tool, including a cutter body 1, a mounting table 2, and a machined stage 3. The bottom portion of the cutter body 1 is fixedly mounted, and the side surface of the mounting table 2 is provided. The processing table 3, the back surface of the processing table 3 is fixedly mounted, and the side surface of the fixing mechanism is provided with the cleaning mechanism 31, the cleaning mechanism 31 includes a moving mechanism 32, and the side surface of the moving mechanism 32 is fixedly mounted, and the cleaning plate 33, the cleaning plate 33 The bottom portion is provided with a friction pad 333, and the bottom of the friction pad 333 is provided with a buffer groove, and the internal activity of the buffer groove is attached, and the bottom portion of the connecting post 3343 is provided with a scraping block 334, and the side surface of the blade 334 is fixedly mou...

Embodiment 2

[0040] Such as Figure 1-9 As shown in the basis of the first embodiment, the present invention provides a technical solution: preferably, the inside of the connecting post 3343 is fixedly mounted with a fixing plate 3344, and two sides of the surface of the fixing plate 3344 are provided with a slide 3345, a slide 3345. The internal activity is attached to the other end of the hydraulic rod 3346, and the other end of the chute 3345 is fixedly mounted, and the inner side of the fixed ring 3346 is provided with a press block 3347, and one end of the hydraulic rod 3346 is attached to the surface of the fixing plate 3344, hydraulic rod 3346 The other end is provided with a moving block, and the side of the moving block is disposed on the side of the pressing block 3347.

[0041] In the present embodiment, by the connection post 3343 to the fixing ring 3346, the hydraulic rod 3346 is telescopically, thereby driving the moving block inside the slide 3345, pushing the pressing block 3347...

Embodiment 3

[0043] Second, if Figure 1-9 As shown, the present invention also provides a clamping mechanism of an aluminum alloy profile processing tool, and the clamping mechanism of the aluminum alloy profile processing tool is disposed on the machining stage, and the top portion of the processing stage 3 is fixedly mounted with a fixing plate 34, fixed The top portion of the plate 34 is fixedly mounted having a clamping plate 35, and the bottom fixing of the clamping plate 35 is fixedly connected, and the side surface of the telescopic column 351 is provided with a telescopic block 352, and the inner side of the clamping plate 35 is fixedly mounted having a clamp pad 353. The bottom portion of the clamp pad 353 is fixedly mounted, and the bottom portion of the fixed block 354 is provided with a cushion pad 355. The side surface of the cushion 355 is fixedly mounted, and the retractable rod 3551, and the other side of the telescopic rod 3551 is fixed in the clamping plate. On the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com