Tea processing machine

A processing machine and tea technology, applied in the directions of packaging/bundling items, packaging, wrapping items, etc., can solve the problems of incapable of tea brick packaging, single equipment function, inconvenient packaging and handling of tea, and reduce production costs, improve efficiency, and improve survival. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with embodiment:

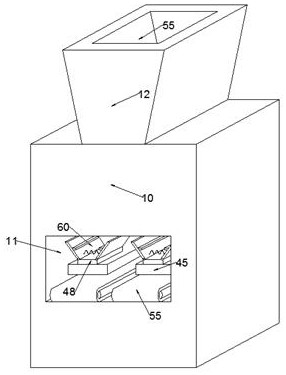

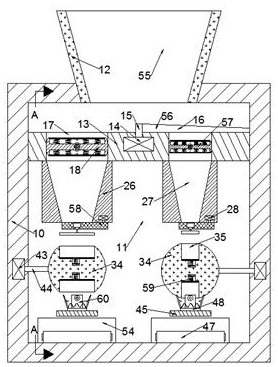

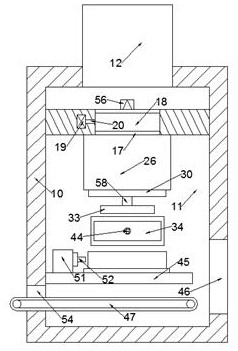

[0038] Refer to attached Figure 1-Figure 7 The shown tea processing machine includes a casing 10, a placement cavity 11 is arranged inside the casing 10, and a funnel 12 extending to the top wall of the placement cavity 11 is fixed on the top wall of the placement cavity 11. The funnel 12 is provided with a feed chamber 55 that penetrates up and down, and a first baffle 13 is fixed on the left and right side walls of the placement chamber 11, and a sweeper for sweeping away tea leaves is fixed on the first baffle 13. Falling device 56;

[0039] The first baffle plate 13 is fixed with drop chambers 17 with symmetrical left and right positions and different sizes, and the two drop chambers 17 with different sizes are provided with quantitative devices 57 for weighing tea leaves with different weights;

[0040] Pipelines 26 of different sizes are respectively fixed below the two quan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com