Coal mine arched section cutting system

A cross-section and arched technology, applied in mining equipment, earth-moving drilling, tunnels, etc., to achieve the effect of strong rock breaking ability, wide application prospect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

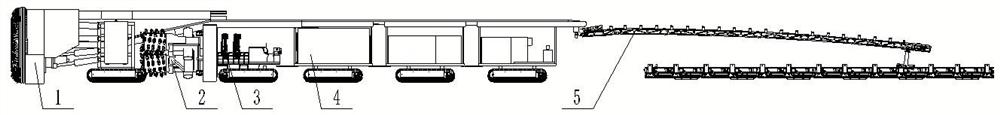

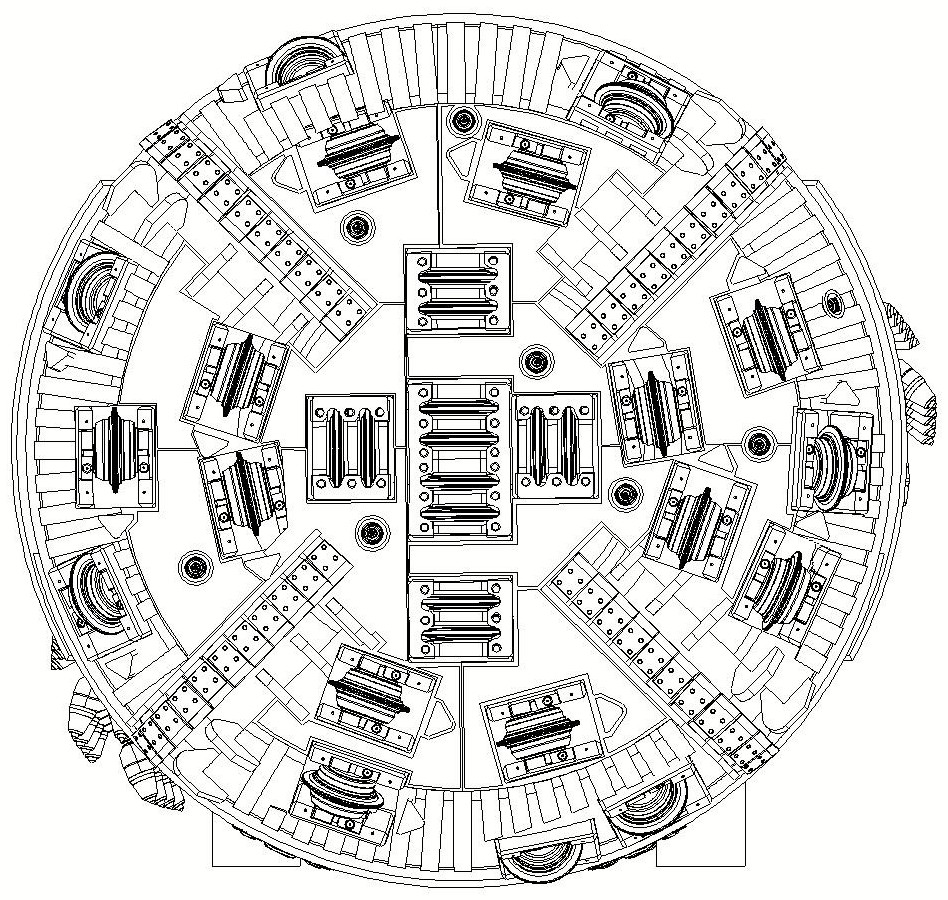

[0019] Such as Figure 1-2 As shown, a coal mine arch section cutting system includes a self-propelled circular section cutting device 1, a follow-up trimming and cutting device 2, an anchor protection system 3, a supporting power system 4 and a material discharge system 5, and the self-propelled The circular section cutting device 1 is arranged at the front end to cut a roadway with a circular section, and the following type trimming and cutting device 2 is arranged behind the self-propelled circular section cutting device 1, and the following type trimming and cutting device 2 is connected with the The self-propelled round section cutting device 1 automatically controls the distance between the two through the distance control system, and the follow-up trimming and cutting device 2 modifies the round section roadway into an arched section roadway, and the follow-up trimming and cutting device 2 An anchor protection system 3 is integrated, which is responsible for completing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com