Fin type heat exchanger

A finned heat exchanger and fin technology, applied in the field of heat exchangers, can solve the problems of vibration and wear of heat exchange tubes, large fluid flow resistance, large heat exchanger volume, etc. heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

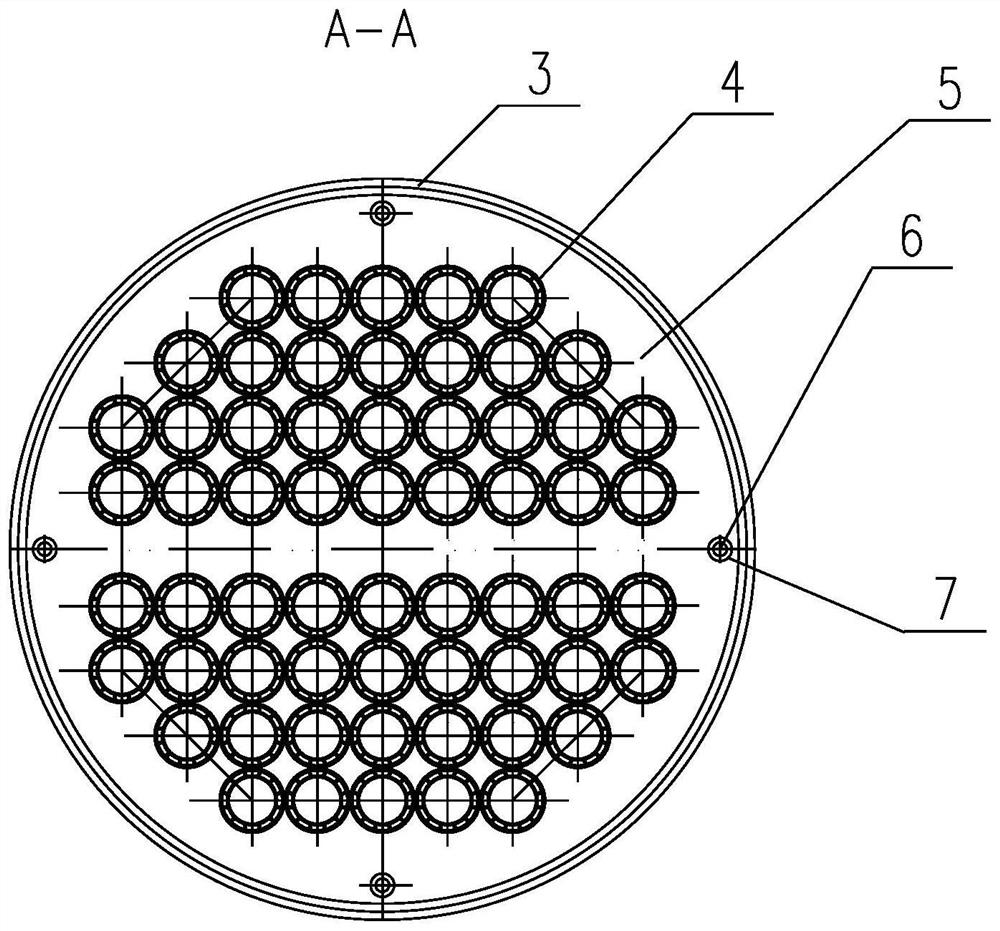

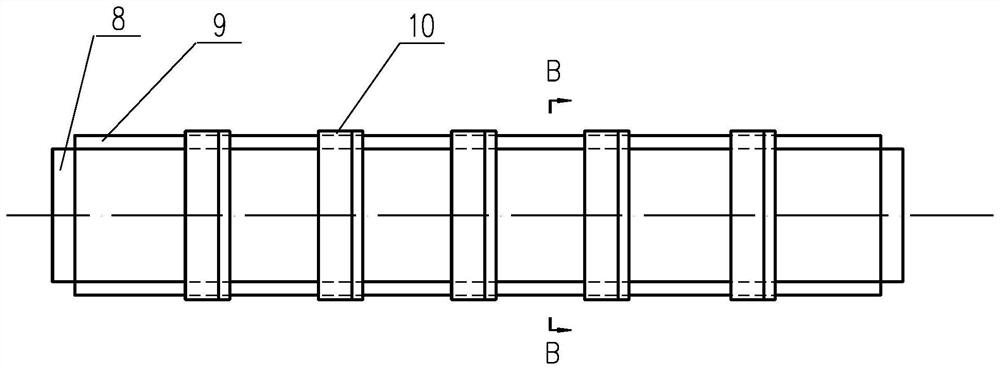

[0022] like Figure 1-5 As shown, a finned heat exchanger includes a tube box 1 , a tube sheet 2 , a cylinder body 3 , a heat exchange tube 4 , a baffle plate 5 , a tie rod 6 and a spacer tube 7 .

[0023] The cylinder body 3 is a circular cylinder body, arranged transversely, and the axis is horizontal. The left end of the cylinder body 3 is connected with the tube sheet 2, and the tube sheet 2 is connected with the tube box 1, and the axis lines of the tube box 1, the tube sheet 2, and the cylinder body 3 are the same.

[0024] Both ends of the tie rod 6 are provided with studs, the tie rod 6 is fixed on the tube plate 2 through threads, the baffles 5 and the spacer tubes 7 are staggeredly sleeved on the tie rod 6, the baffles 5 are full ring plates, and the outer edge Four tie rod holes are evenly distributed on the circumference, and the spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com