Composite board surface flatness quality detection equipment

A technology for surface flatness and testing equipment, which is used in mechanical roughness/irregularity measurement, measuring device, mechanical measuring device, etc., and can solve problems such as manual manual feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

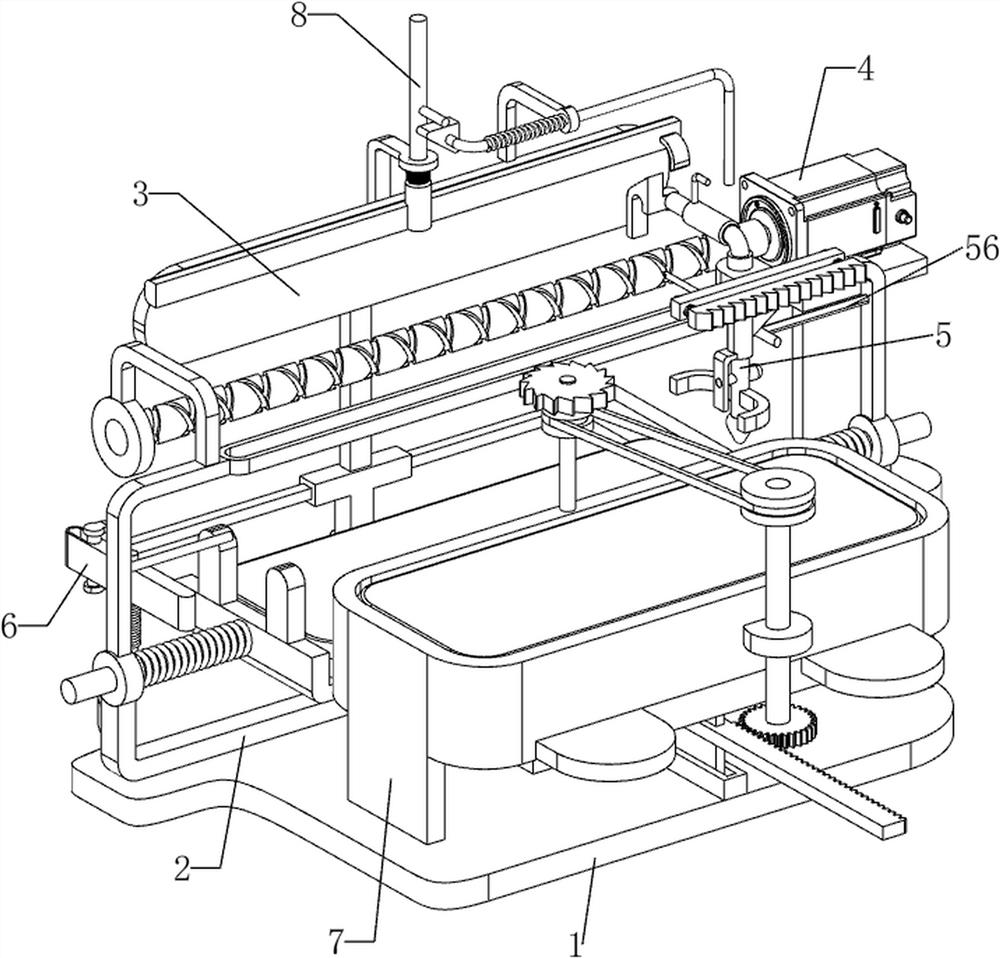

[0072] A composite board surface flatness quality testing equipment, such as figure 1 , figure 2 and Figure 4 As shown, it includes a bottom plate 1, a clamping mechanism 2, a detection mechanism 3 and a lifting mechanism 5, the bottom plate 1 is provided with a clamping mechanism 2, the clamping mechanism 2 is provided with a detection mechanism 3, and the detection mechanism 3 is provided with a lifting mechanism 5.

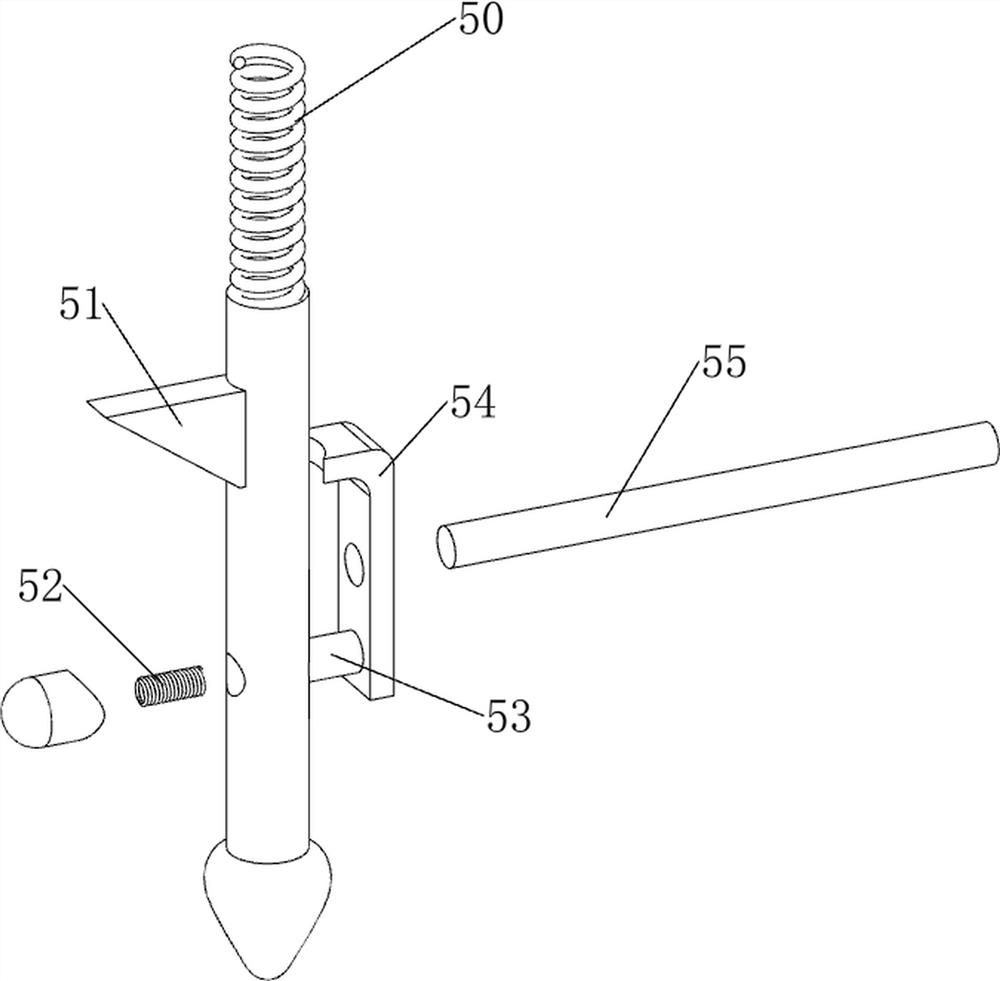

[0073]When people need to use this device, first people pull the clamping mechanism 2 apart, then place the composite board in the clamping mechanism 2, and then loosen the clamping mechanism 2, so that the clamping mechanism 2 clamps the composite board, In the initial state, the detection mechanism 3 and the lifting mechanism 5 are located above the left side of the bottom plate 1, and then people push the detection mechanism 3 and the lifting mechanism 5 to the right. When the lifting mechanism 5 contacts the composite board, the lifting mechanism 5 dete...

Embodiment 2

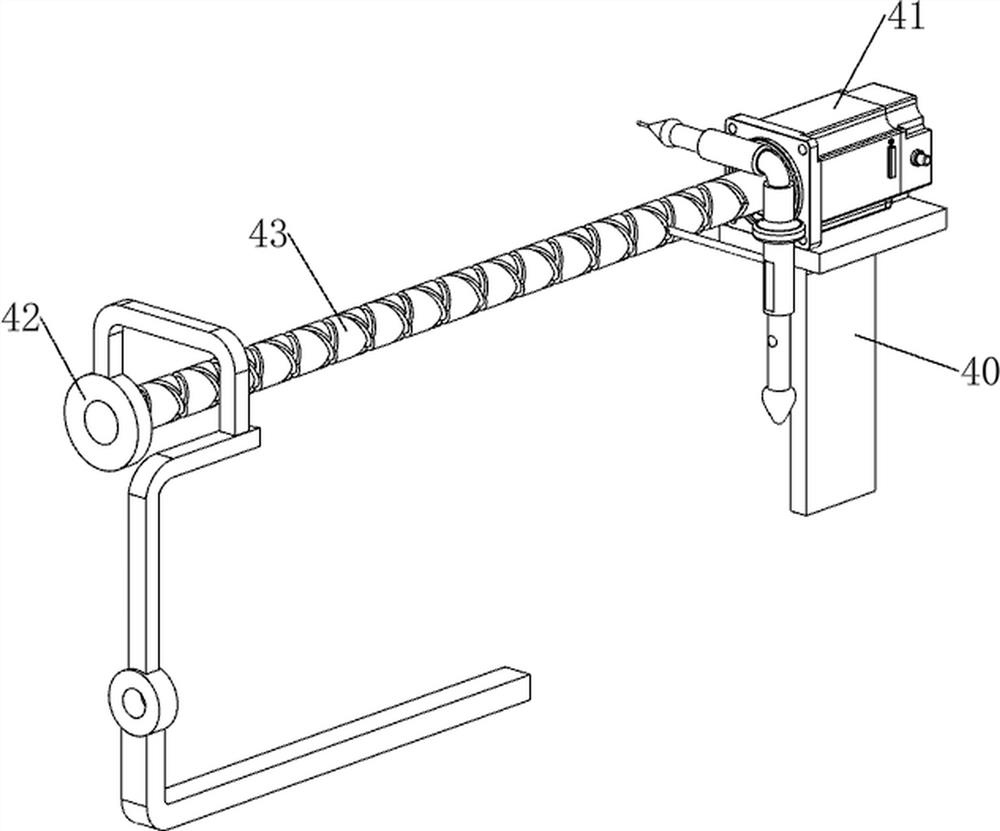

[0079] On the basis of Example 1, such as figure 1 , image 3 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a moving mechanism 4 is also included. The moving mechanism 4 includes a support plate 40, a servo motor 41, a bearing seat 42 and a twist shaft 43. The right side of the bottom plate 1 is provided with a support plate 40, and the support plate 40 is provided with a servo motor 41. The left side of the slide rail 30 is provided with a bearing seat 42, the bearing seat 42 is provided with a twist shaft 43, the twist shaft 43 is connected with the output shaft of the servo motor 41, and the slide block and the twist shaft 43 are slidably matched.

[0080] After the composite board is placed, the servo motor 41 can be started, and the output shaft of the servo motor 41 drives the twist shaft 43 to rotate, and the twist shaft 43 then drives the slider to move left and right, so that there is no need to manually move the slider. During equipment, close serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com