Mining optical cable and assembly thereof

A technology of optical cable components and optical cables, which is applied in optical components, light guides, optics, etc., can solve the problems of heavy weight of optical cables used in mining and cannot be paralleled to expand capacity, etc., and achieve the effects of reducing the weight of optical cables, good compressive performance, and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

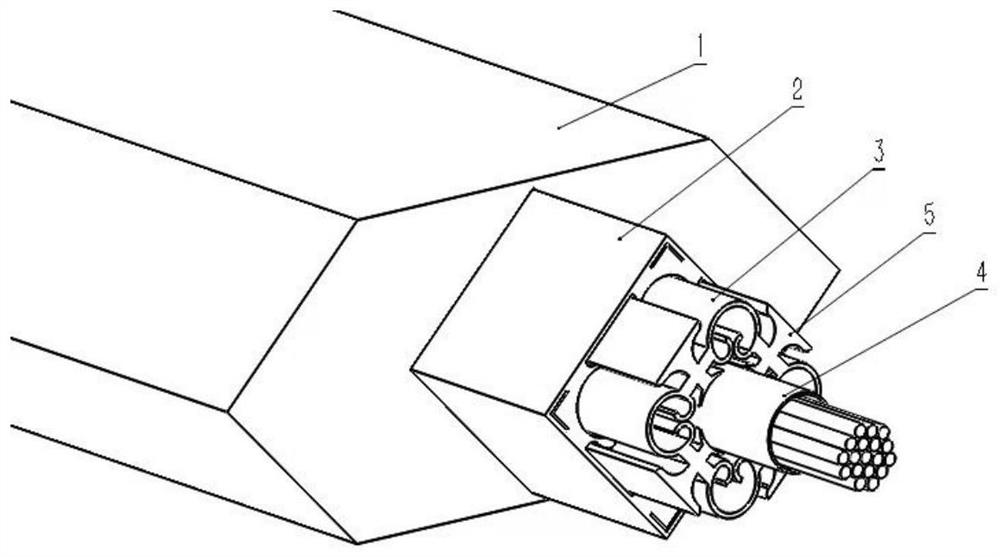

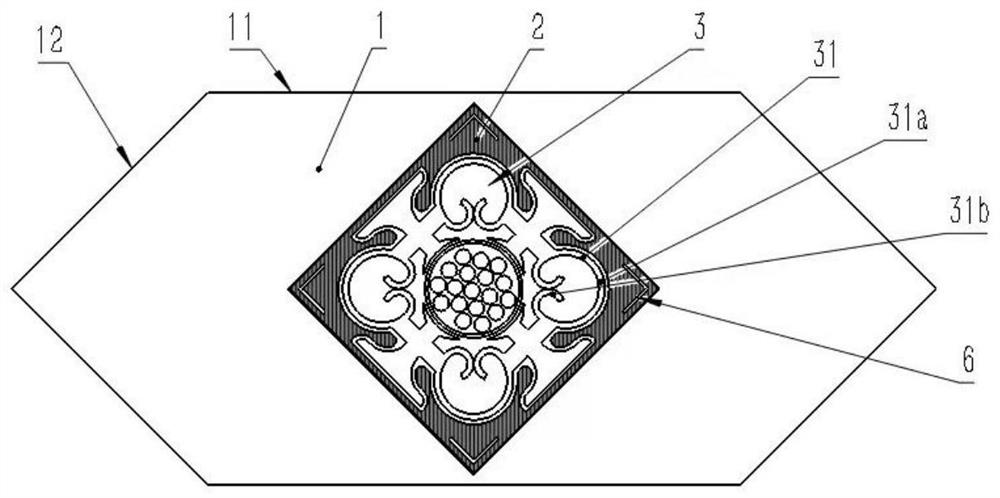

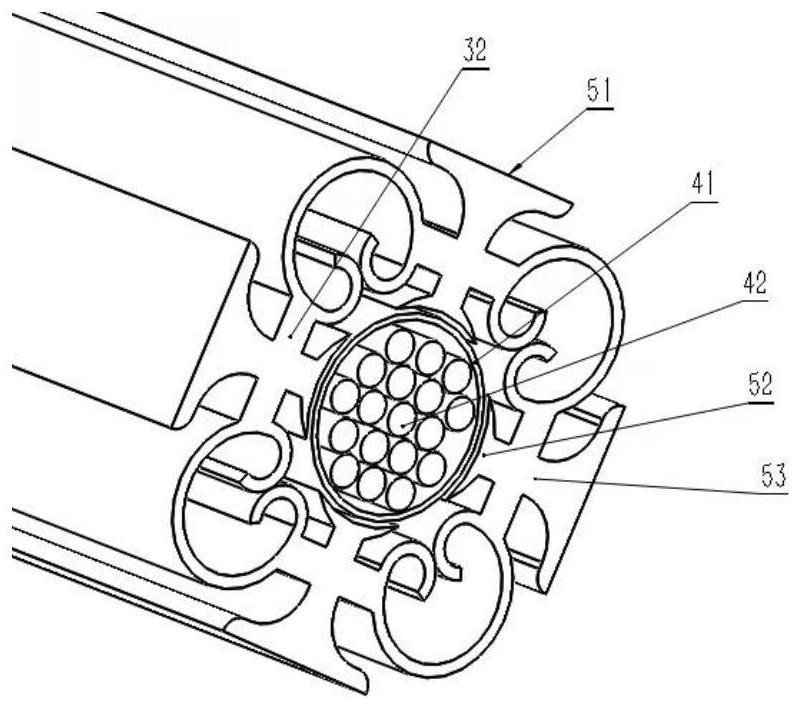

[0039] Such as figure 1 , 2 As shown, a mining optical cable is sequentially provided with a secondary sheath 1, a primary sheath 2, a skeleton 3 and an optical unit 4 from outside to inside.

[0040] The secondary sheath has a hexagonal cross-section and is composed of two parallel long sections 11 of equal length on the upper and lower sides and four short sections 12 of equal length on the left and right sides. Adjacent short sections form a group, and two sets of short sections The sections respectively form two outward-facing vertices in the horizontal direction of the hexagon of the secondary sheath, and the hexagon is symmetrical up and down with the line connecting the horizontal vertices as the line of symmetry.

[0041] The primary sheath is set in the secondary sheath, the cross section is square, the intersection point of the two diagonals of the square is the axis of the optical cable, and the extension of the diagonals of the square passes through two of the sec...

Embodiment 2

[0051] On the basis of embodiment 1, the mine optical cable is further improved, adhesive tape is set on the upper and / or lower side of the mine optical cable in embodiment 1, and the adhesive tape 7 can be passed between two mine optical cables Realize the longitudinal connection to form the longitudinal assembly of the mine optical cable, specifically as Figure 5 shown.

[0052] In addition, at the two horizontal vertices of the secondary sheath of the mine optical cable, an arc slot 8 recessed inward and an arc-shaped plug 9 protruding outward are respectively provided. The above-mentioned mining optical cables are connected horizontally through the cooperation of slots and plugs, such as Figure 6 As shown, the plug of the mine optical cable on the left is adapted to be inserted into the slot of the right mine optical cable, and the plug of the right mine optical cable continues to connect to the new slot to the right, and the two are connected to form a horizontal assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com