Molecular sieve-based glass fiber framework adsorbing material as well as preparation method and application thereof

A glass fiber and adsorption material technology, which is applied in the field of molecular sieve-based glass fiber skeleton adsorption materials and its preparation, can solve the problems of low solid content of molecular sieves, uneven dispersion of molecular sieves, and no adsorption effect, and achieves a simple and reasonable preparation method. The effect of reducing molecular sieve content and avoiding waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

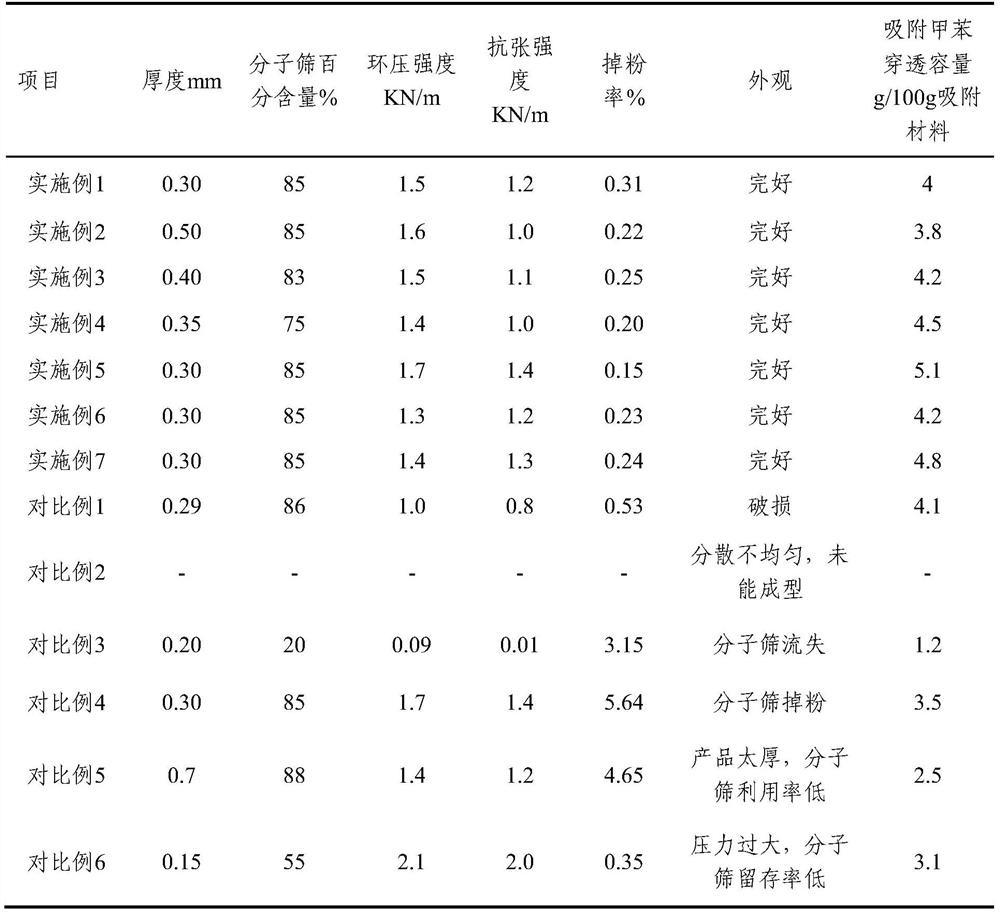

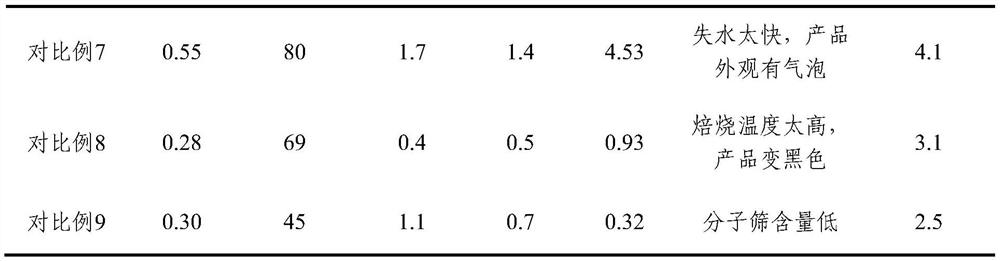

Examples

Embodiment 1

[0055] A method for preparing a molecular sieve-based glass fiber skeleton adsorption material, comprising the steps of:

[0056] S100: Weigh 1 g of polyethylene oxide with a molecular weight of 20 million and 10,000 g of deionized water, stir them evenly, and prepare an aqueous solution of polyethylene oxide with a mass concentration of 0.01% for later use.

[0057] S200: Weigh 10 g of wood pulp fiber and 90 g of glass fiber respectively, and set aside. The wood pulp fiber is coniferous wood pulp cellulose with a length of 3 mm and a diameter of 50 μm; the glass fiber is an alkali-free glass fiber with a length of 4 mm and a diameter of 7 μm.

[0058] S300: After mixing the glass fiber and wood pulp fiber weighed by S200, put it in a standard fiber de-flatter, add 1000g of deionized water, and then de-fibrillate the fiber; Filter off excess water; according to the amount of polyethylene oxide added to be 1% of the mass of glass fiber, add 9000g of the solution prepared by S1...

Embodiment 2

[0064] A method for preparing a molecular sieve-based glass fiber skeleton adsorption material, comprising the steps of:

[0065] S100: Weigh 2 g of polyacrylamide with a molecular weight of 30 million and 10,000 g of deionized water, stir them evenly, and prepare an aqueous solution of polyacrylamide with a mass concentration of 0.02% for later use.

[0066] S200: Weigh 20 g of wood pulp fiber and 80 g of glass fiber respectively, and set aside. The wood pulp fiber is broad-leaved wood pulp cellulose with a length of 4 mm and a diameter of 60 μm; the glass fiber is medium-alkali glass fiber with a length of 4 mm and a diameter of 7 μm.

[0067] S300: After mixing the glass fiber and wood pulp fiber weighed by S200, put it in a standard fiber deconcentrator, add 1000g of deionized water, and then demineralize the fiber; the speed of the demineralizer is set to 20000rad / min, and the deconcentration time is 3min. Filter off the excess water; according to the amount of polyacryl...

Embodiment 3

[0073] A method for preparing a molecular sieve-based glass fiber skeleton adsorption material, comprising the steps of:

[0074] S100: Weigh 2 g of polyethylene oxide with a molecular weight of 20 million and 10,000 g of deionized water, stir them evenly, and prepare an aqueous solution of polyethylene oxide with a mass concentration of 0.02% for later use.

[0075] S200: Weigh 15g of wood pulp fiber and 85g of glass fiber respectively, and set aside. The wood pulp fibers are coniferous wood pulp fibers with a length of 3 mm and a diameter of 50 μm; the glass fibers are alkali-free glass fibers with a length of 4 mm and a diameter of 7 μm.

[0076] S300: After mixing the glass fiber and wood pulp fiber weighed by S200, put it in a standard fiber de-flatter, add 1000g of deionized water, and then de-fiber the fiber; set the speed of the de-flaker to 10000rad / min, and the de-flatter time to 3min. Filter off excess water; according to the amount of polyethylene oxide added to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com