Lightweight and insulating interior wall brick and production method thereof

An interior wall, lightweight technology, applied in the field of lightweight thermal insulation interior wall tiles and their preparation, can solve the problems of heavy weight, general compressive performance, low thermal insulation effect, etc., and achieve light weight, excellent thermal insulation effect, and stable product performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

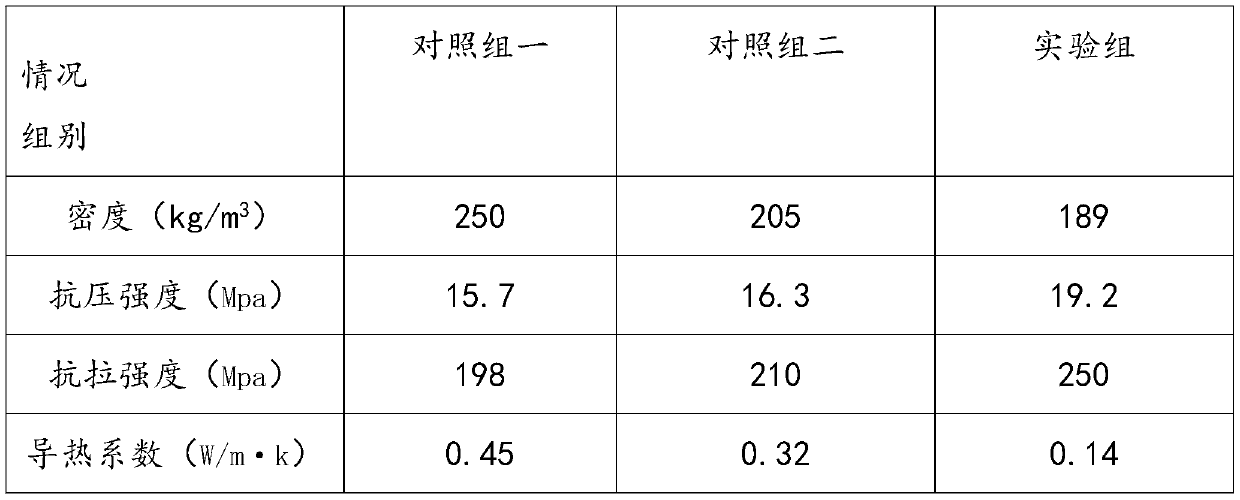

Examples

Embodiment 1

[0021] A lightweight thermal insulation interior wall brick is made of the following raw materials in parts by weight: 40 parts of cement, 3 parts of ceramsite, 9 parts of diatomite, 1 part of saponin, 6 parts of plant ash, 3 parts of flax fiber, and 1 part of calcium carbonate , 0.2 parts of magnesium oxide, 0.1 parts of sodium tripolyphosphate, 2 parts of paraffin, 1 part of calcium stearate, 3 parts of triethanolamine, 8 parts of phenolic resin, 5 parts of diphenyl phosphate and 50 parts of hard water.

[0022] A method for preparing light-weight thermal insulation interior wall bricks, comprising the following steps:

[0023] 1) Put 40 parts of cement, 3 parts of ceramsite, 9 parts of diatomaceous earth and 6 parts of plant ash into a pulverizer, pulverize at a speed of 1000r / min for 10 minutes, and then pass through a 50-mesh sieve to obtain a mixed powder for later use;

[0024] 2) Put 1 part of calcium carbonate, 0.2 part of magnesium oxide, 1 part of calcium stearate a...

Embodiment 2

[0032] A lightweight thermal insulation interior wall brick is made of the following raw materials in parts by weight: 30 parts of cement, 5 parts of ceramsite, 11 parts of diatomite, 3 parts of saponin, 8 parts of plant ash, 5 parts of flax fiber, and 2 parts of calcium carbonate , 0.4 parts of magnesium oxide, 0.3 parts of sodium tripolyphosphate, 3 parts of paraffin, 2 parts of calcium stearate, 5 parts of triethanolamine, 10 parts of phenolic resin, 7 parts of diphenyl phosphate and 70 parts of hard water.

[0033] A method for preparing light-weight thermal insulation interior wall bricks, comprising the following steps:

[0034] 1) Put 30 parts of cement, 5 parts of ceramsite, 11 parts of diatomaceous earth and 8 parts of plant ash into a pulverizer, pulverize at a speed of 1200r / min for 15 minutes, and then pass through a 80-mesh sieve to obtain a mixed powder for later use;

[0035] 2) Put 2 parts of calcium carbonate, 0.4 parts of magnesium oxide, 2 parts of calcium s...

Embodiment 3

[0043] A lightweight thermal insulation interior wall brick is made of the following raw materials in parts by weight: 35 parts of cement, 4 parts of ceramsite, 10 parts of diatomite, 2 parts of saponin, 7 parts of plant ash, 4 parts of flax fiber, and 1.5 parts of calcium carbonate , 0.3 parts of magnesium oxide, 0.2 parts of sodium tripolyphosphate, 2.5 parts of paraffin, 1.5 parts of calcium stearate, 4 parts of triethanolamine, 9 parts of phenolic resin, 6 parts of diphenyl phosphate and 60 parts of hard water.

[0044] A method for preparing light-weight thermal insulation interior wall bricks, comprising the following steps:

[0045] 1) Put 35 parts of cement, 4 parts of ceramsite, 10 parts of diatomaceous earth and 7 parts of plant ash into a pulverizer, pulverize at a speed of 1100r / min for 13 minutes, and then pass through a 70-mesh sieve to obtain a mixed powder for later use;

[0046] 2) Put 1.5 parts of calcium carbonate, 0.3 parts of magnesium oxide, 1.5 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com