Multifunctional pipe and method for preparing same

A multi-functional, outer rubber layer technology, applied in the field of hoses, can solve the problems of increased cost, single function, increased manpower and material consumption, etc., to achieve the effect of prolonging the service life, good compression resistance and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

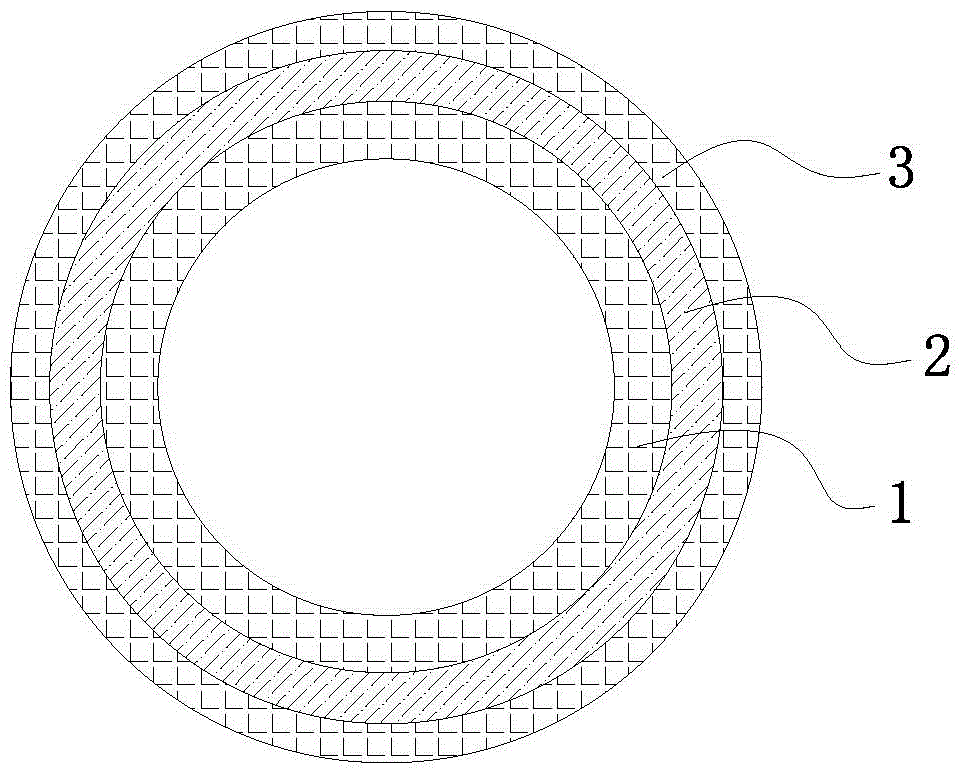

[0014] Such as figure 1 As shown, a multifunctional pipe includes an inner rubber layer 1, an outer rubber layer 3, and a fiber braided layer 2. The outer rubber layer 3 is the outermost layer, and the fiber braided 2 layers are arranged on the inner rubber layer 4 and the outer rubber layer 4. Between the adhesive layers 3, the fiber braided layer 2 is woven from polyester fibers; polyester fibers have good strength and elastic recovery properties, and have a good reinforcing effect on the overall performance, so that the overall performance of the multi-functional pipe The tensile performance and compressive performance are better, and the material is easy to obtain and the cost is low.

[0015] The inner rubber layer is prepared from the following materials: 100 parts of nitrile rubber, 5.5 parts of zinc oxide, 2.5 parts of stearic acid, 5 parts of anti-aging agent, 3.5 parts of dispersant, 11 parts of kaolin, 100 parts of N660 carbon black, 15.5 parts of DOTP, 1.5 parts o...

Embodiment 2

[0020] Such as figure 1 As shown, a multifunctional pipe includes an inner rubber layer 1, an outer rubber layer 3, and a fiber braided layer 2. The outer rubber layer 3 is the outermost layer, and the fiber braided 2 layers are arranged on the inner rubber layer 4 and the outer rubber layer 4. Between the adhesive layers 3, the fiber braided layer 2 is woven from polyester fibers; polyester fibers have good strength and elastic recovery properties, and have a good reinforcing effect on the overall performance, so that the overall performance of the multi-functional pipe The tensile performance and compressive performance are better, and the material is easy to obtain and the cost is low.

[0021] The inner rubber layer is prepared from the following materials: 100 parts of nitrile rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 4 parts of anti-aging agent, 3 parts of dispersant, 10 parts of kaolin, 90 parts of N660 carbon black, 15 parts of DOTP, 1 part of sulfur, 4 ...

Embodiment 3

[0026] Such as figure 1As shown, a multifunctional pipe includes an inner rubber layer 1, an outer rubber layer 3, and a fiber braided layer 2. The outer rubber layer 3 is the outermost layer, and the fiber braided 2 layers are arranged on the inner rubber layer 4 and the outer rubber layer 4. Between the adhesive layers 3, the fiber braided layer 2 is woven from polyester fibers; polyester fibers have good strength and elastic recovery properties, and have a good reinforcing effect on the overall performance, so that the overall performance of the multi-functional pipe The tensile performance and compressive performance are better, and the material is easy to obtain and the cost is low.

[0027] The inner rubber layer is prepared from the following materials: 100 parts of nitrile rubber, 6 parts of zinc oxide, 3 parts of stearic acid, 6 parts of anti-aging agent, 4 parts of dispersant, 12 parts of kaolin, 110 parts of N660 carbon black, 16 parts of DOTP, 2 parts of sulfur, 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com