Unconventional steel plate wafer cutting device and implementation method thereof

An unconventional, steel plate technology, applied in the field of stamping, can solve problems such as material waste, achieve the effects of improving processing efficiency, fast blanking, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

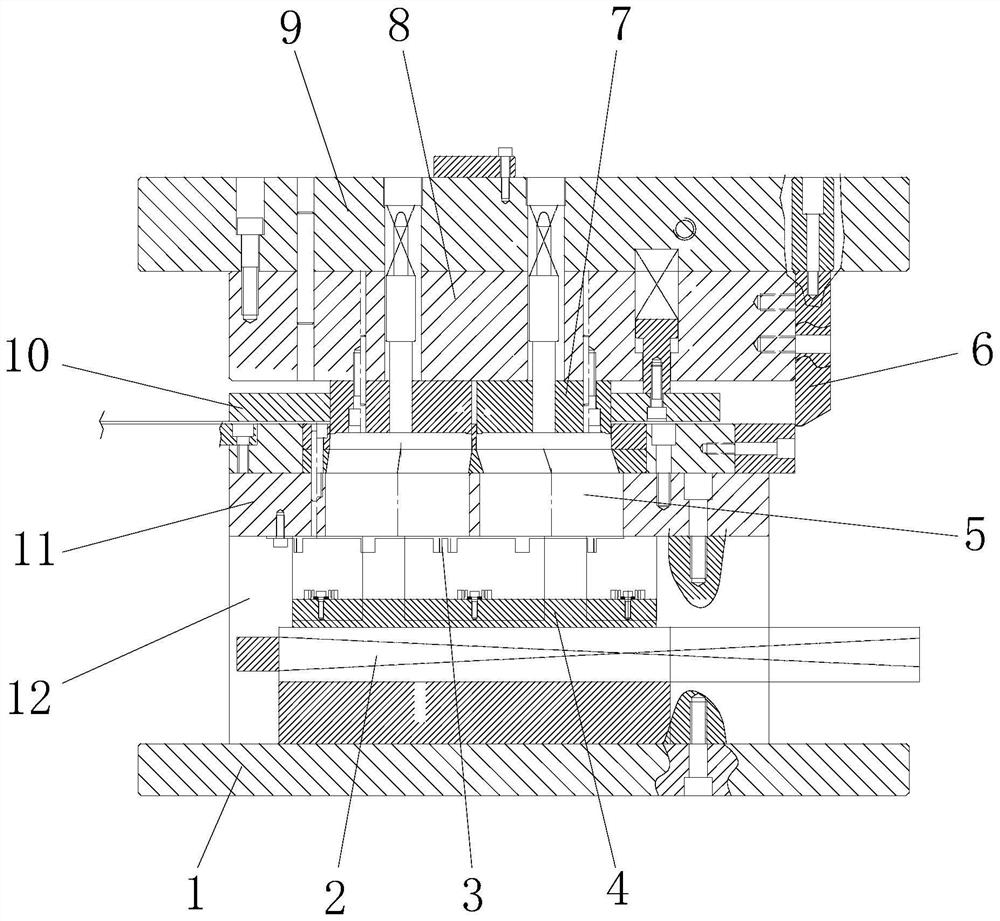

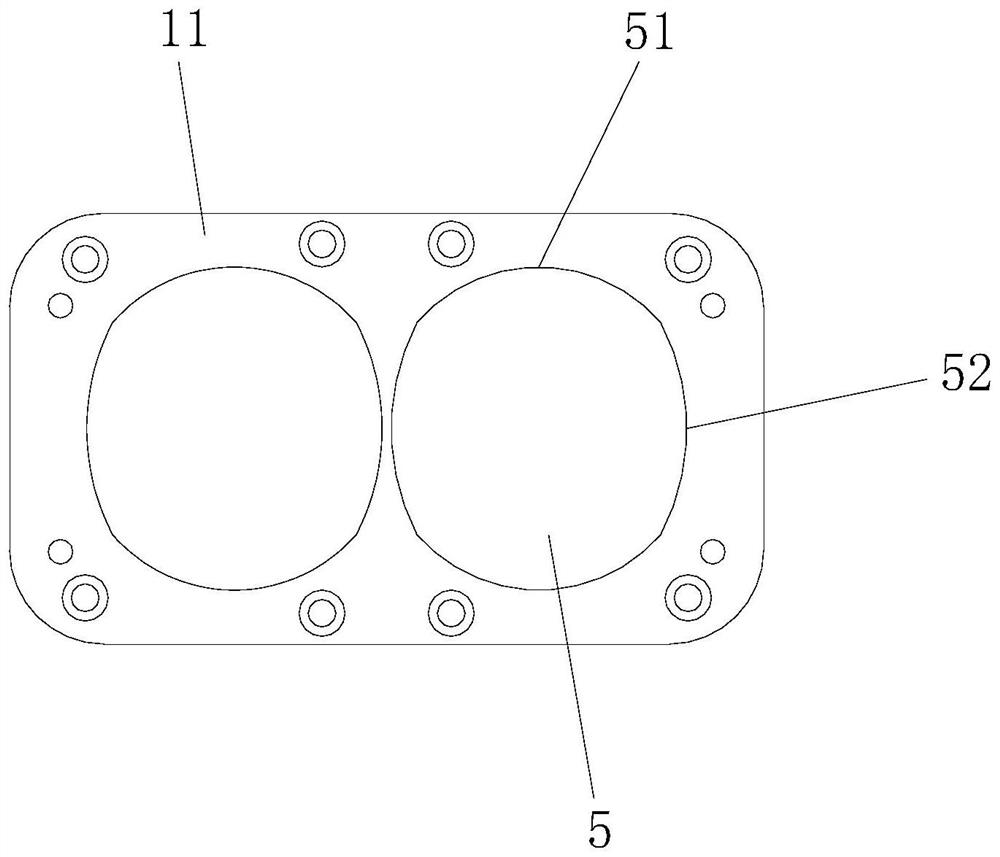

[0038] see Figure 1-8 , the present invention provides the following technical solutions: an unconventional steel plate disc cutting device, comprising a lower fixing seat 1 and an upper fixing seat 9 located above the lower fixing seat 1, a die seat 12 is arranged above the lower fixing seat 1, A die 11 is provided above the die base 12, and two symmetrical cavities 5 are arranged inside the die 11. The die cavity 5 includes two oppositely arranged first arc edges 51 and two oppositely arranged second arc edges. side 52, and the radius of the first arc edge 51 is smaller than the radius of the second arc edge 52, the punch seat 8 is provided below the upper fixed seat 9, and the punch seat 8 is provided with two corresponding to the cavity 5. Punch 7.

[0039] By adopting the above-mentioned technical scheme, the punch 7 and the cavity 5 are designed as a double-flat structure corresponding to the disc product, and the steel plate material with the same area can punch out m...

Embodiment 2

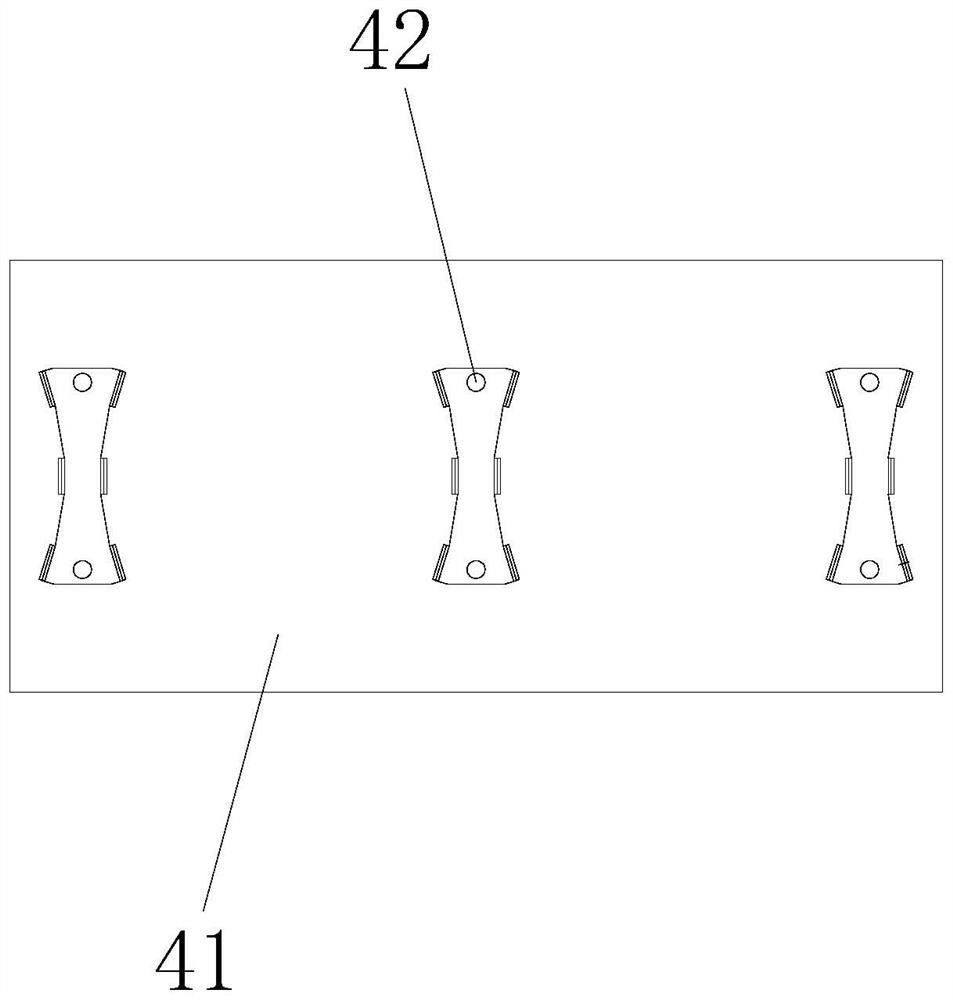

[0045] The difference between this embodiment and Embodiment 1 is that specifically, the inside of the die base 12 is provided with a moving module 2, the moving module 2 is a linear module, purchased from the market, and the output end of the moving module 2 is A mobile platform 4 corresponding to the cavity is provided.

[0046] By adopting the above-mentioned technical solution, the mobile module 2 drives the mobile table 4 to move, so that the punched out double-flat wafer products are delivered to the outside of the mould, and the rapid unloading of the double-flat wafer products is realized.

[0047] Specifically, the mobile station 4 includes a base 41, the base 41 is installed on the output end of the mobile module 2, the base 41 is provided with three positioning blocks 42 at equal intervals, the sides of the positioning blocks 42 are arc-shaped structures, and the three positioning blocks Two positioning spaces corresponding to the cavity 5 are formed between the blo...

Embodiment 3

[0050] This embodiment differs from Embodiment 1 in that: specifically, a number of spacers 421 are provided on the side wall of the positioning block 42 , and a slope is provided on the side of the spacer 421 far away from the positioning block 42 .

[0051] By adopting the above technical solution, the positioning of the double-flat wafer product is more precise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com