Quick positioning and mounting method for double I-shaped beams on cabin section of container ship

A container ship, positioning and installation technology, applied to ships and other directions, can solve the problems of difficulty in correction, serious labor waste, and restriction of segmental construction cycle, and achieve the effects of shortening the production cycle, avoiding repeated corrections, and ensuring installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

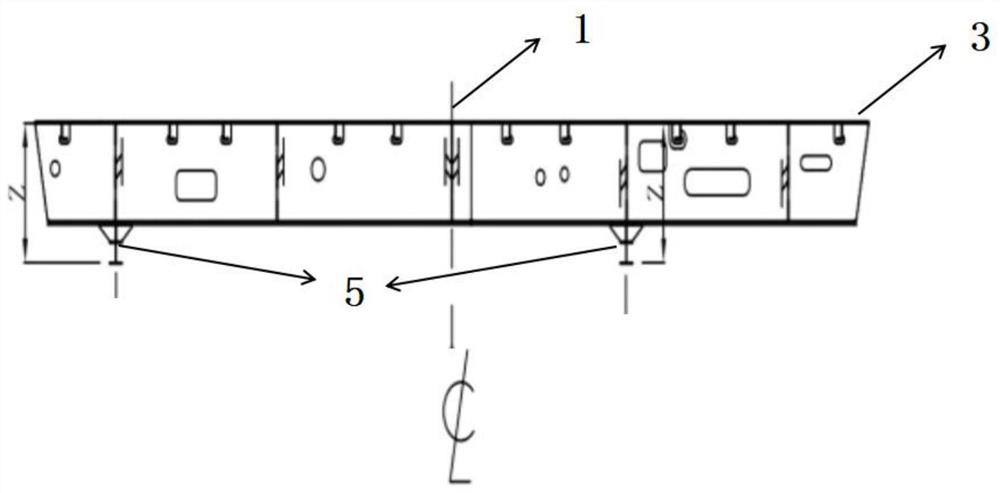

[0036] The installation and inspection method of the double I-beam of the present invention is applied to the engine room section of a large container ship of a certain type. The application process specifically includes the following:

[0037] Step 1, the inspection method for the installation accuracy of incoming I-beams. After the I-beam arrives, place the I-beam in a free state, and use a level to confirm the straightness and main dimension of the I-beam. The straightness is ±2mm, and the main dimension is ±3mm. If the accuracy is out of tolerance, it must be returned to the factory for correction or fired. work adjustment.

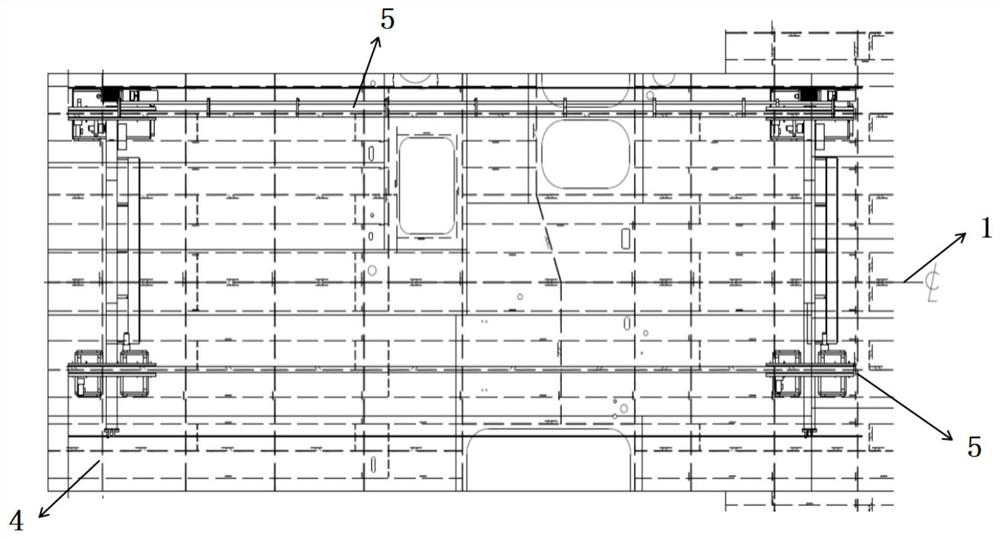

[0038] Step: 2. Control and check the accuracy of panel assembly and component installation of the engine room main board.

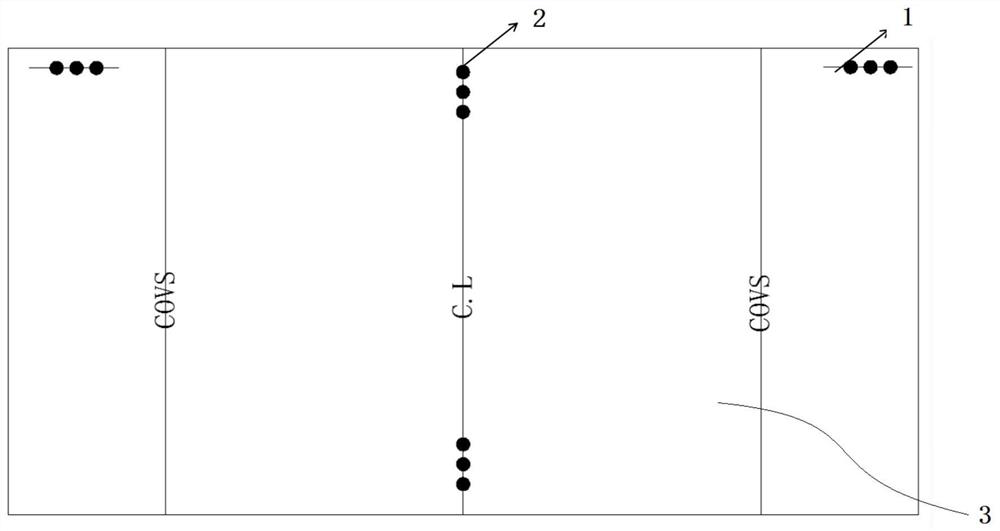

[0039] like figure 1 As shown, in the assembly stage of the main deck 3, the main dimensions and squareness of the main deck 3 are checked according to the theoretical data, and the bow 150MK datum line 1 is marked at the dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com