Sedimentation and sludge discharge method of tertiary sedimentation tank

A settling tank and sludge technology, applied in the direction of sedimentation separation, separation methods, chemical instruments and methods, etc., can solve the problems of severe disturbance, water COD exceeding the standard, and pile up a layer of sludge, etc., to achieve accelerated adhesion, increase rate, and reduce The effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific examples.

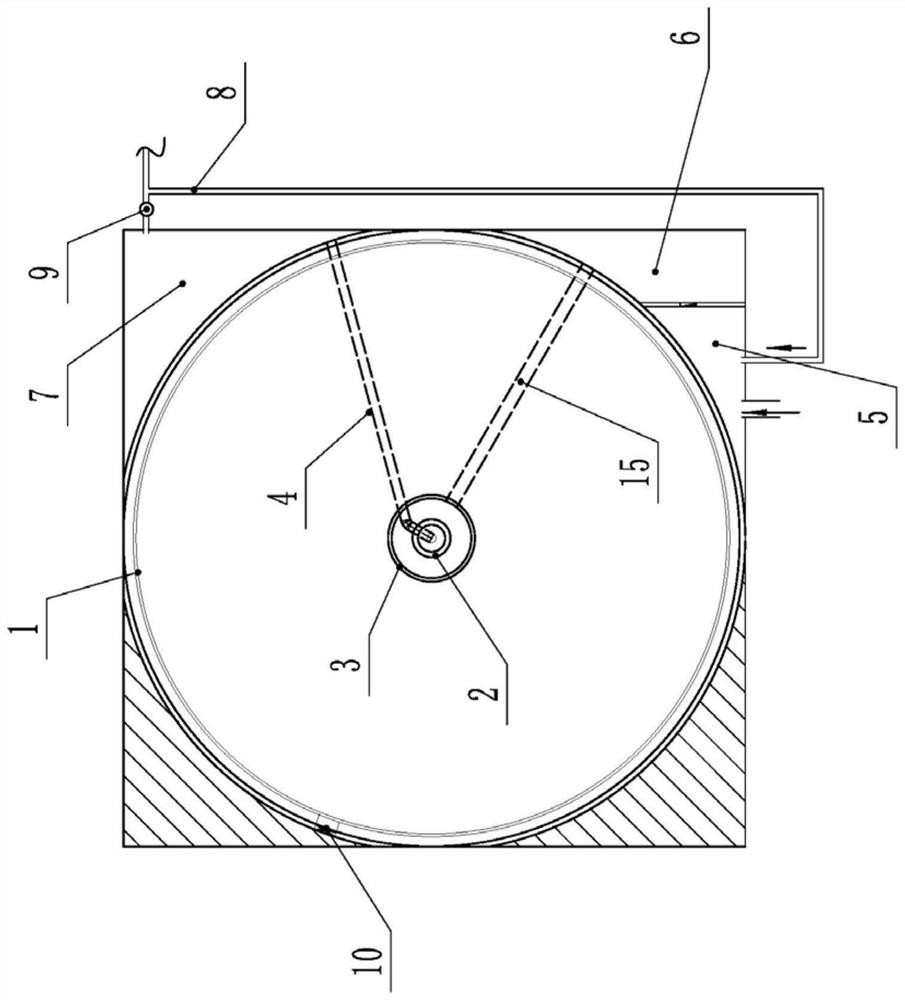

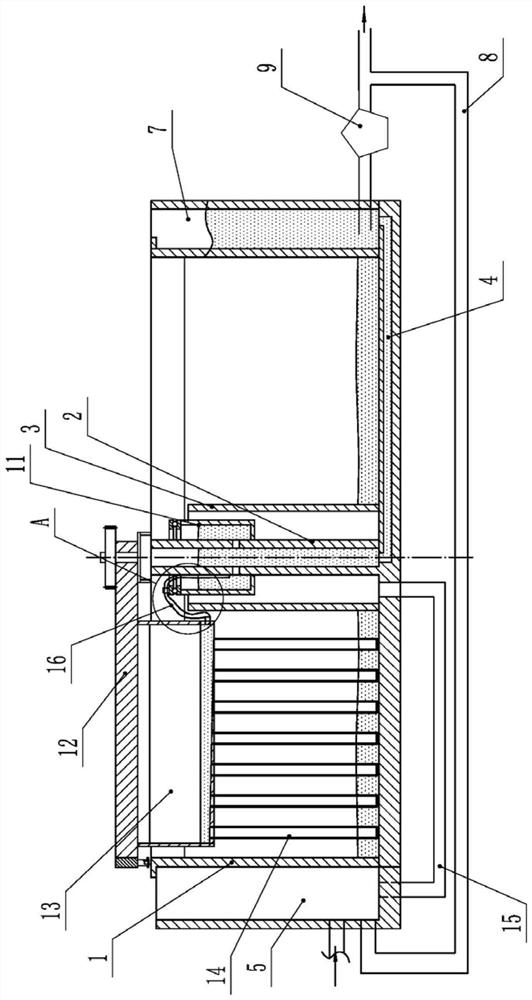

[0025] like Figure 1 to Figure 4 Shown, a kind of sedimentation mud discharge method of three settling tanks, this method comprises the following steps:

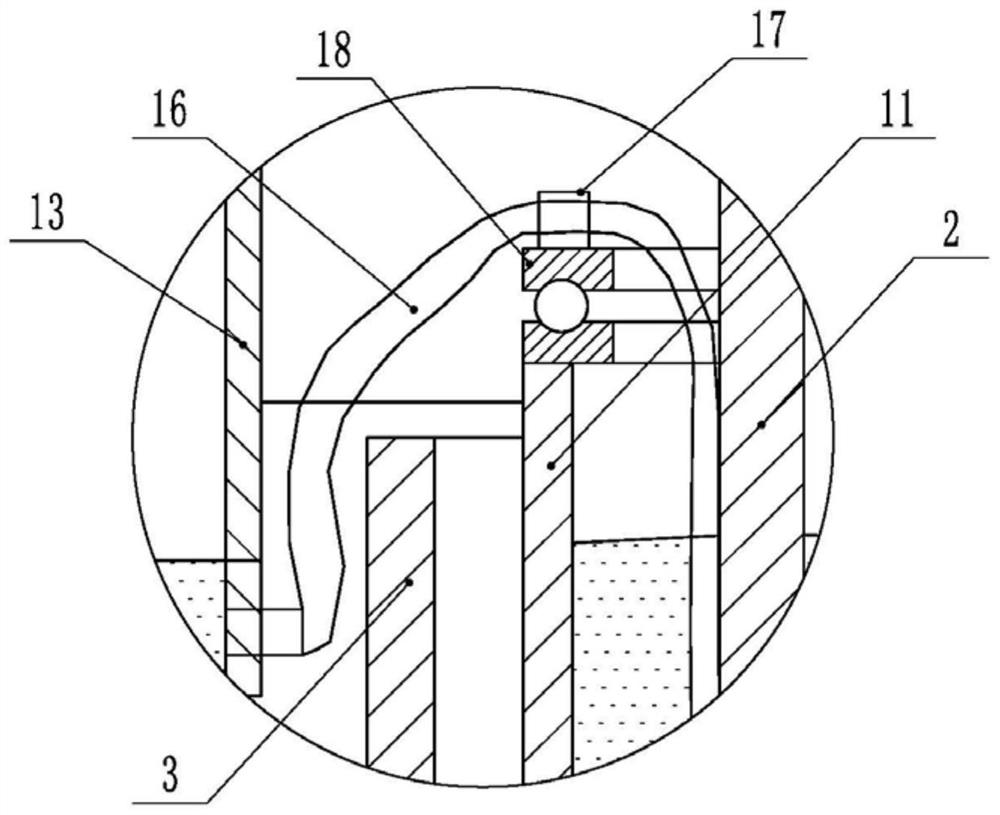

[0026] S1, provide a triple sedimentation tank, including a tank body 1, the outside of the tank body 1 is provided with a PAC addition pool 5, a PAM addition pool 6 and a sludge pool 7, between the PAC addition pool 5 and the PAM addition pool 6 The sludge tank 7 is connected with a mud outlet pipe, the mud outlet pipe is provided with a mud outlet pump 9, and the middle part of the pool body 1 is provided with a concentric outer cylinder 3 and an inner cylinder 2, so The PAM addition pool 6 is communicated with the area between the outer cylinder 3 and the inner cylinder 2 through the water inlet pipe 15, and the bottom of the pool 1 is provided with the inner cavity of the inner cylinder 2 and the inner cavity of the slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com