Damping device for BIM-based fabricated constructional engineering

A technology of construction engineering and shock absorption device, which is applied in the direction of protective buildings/shelters, buildings, building components, etc., can solve the problems of strong buffer strength, etc., and achieves enhanced impact strength effect, significant limit effect, and splicing. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

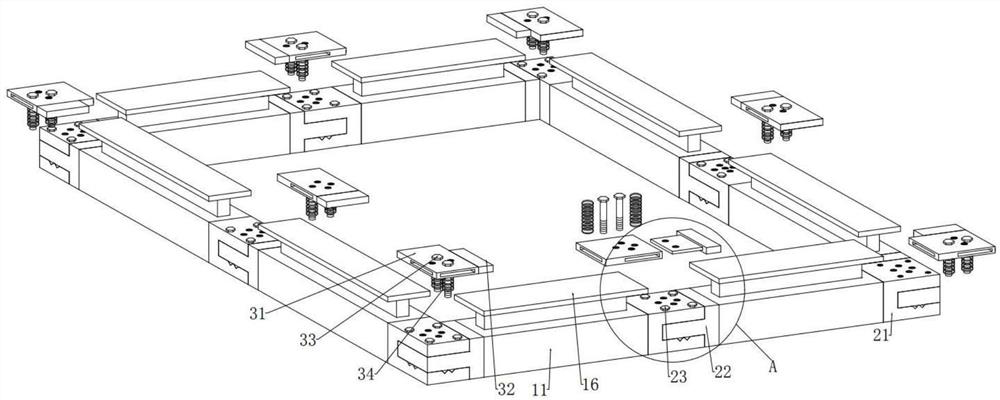

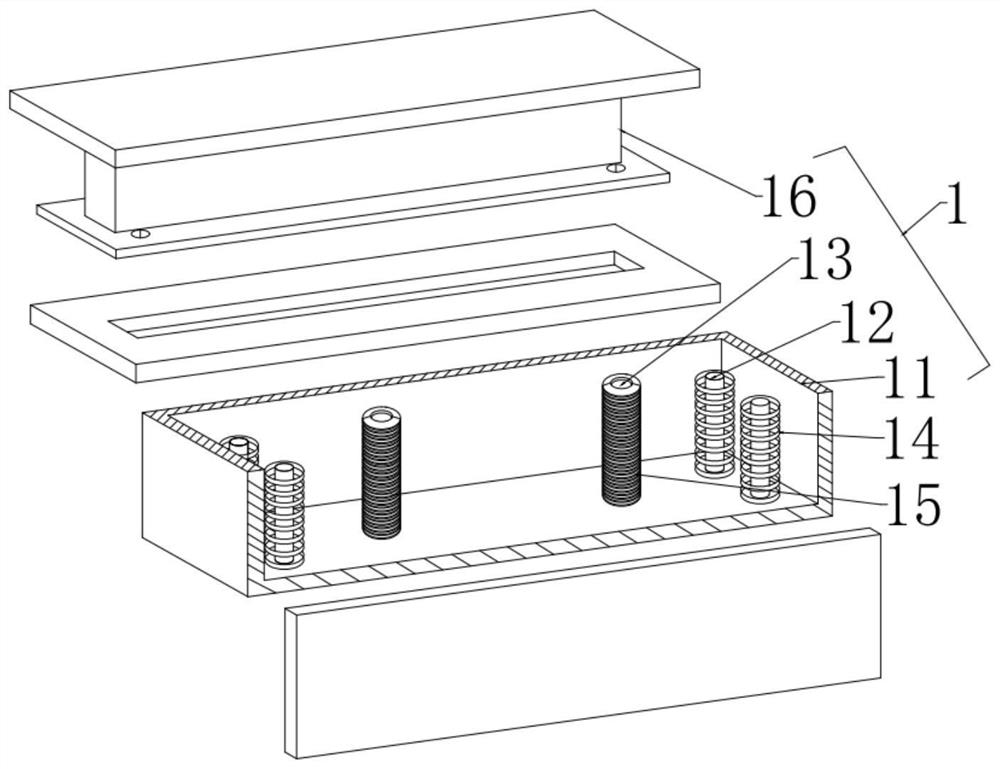

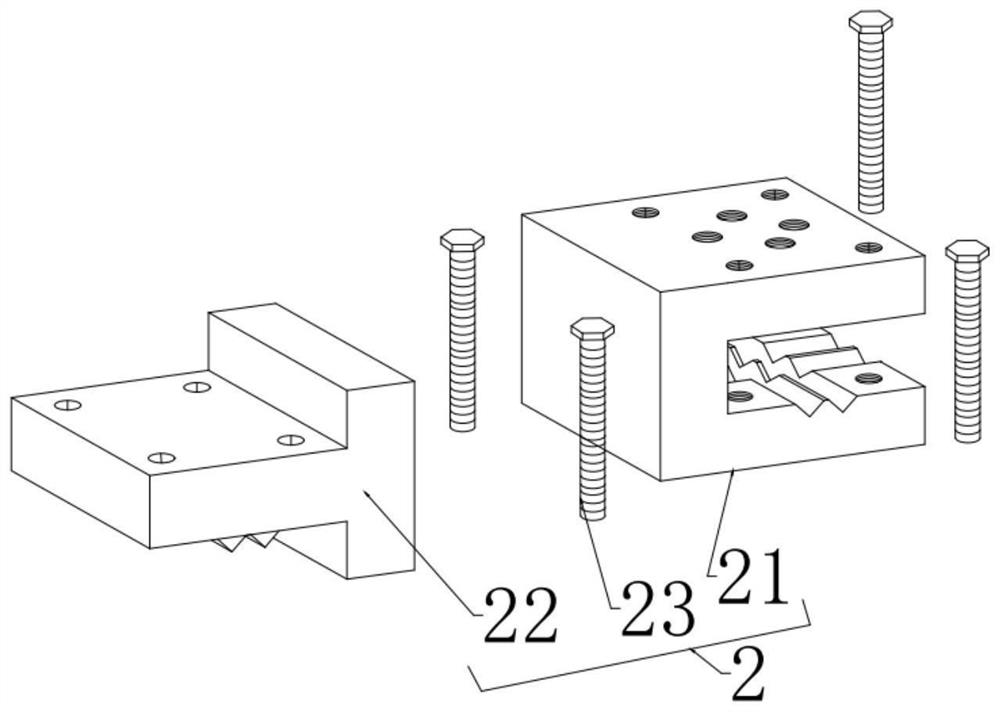

[0041] Embodiment: according to specification Figure 1-6 It can be seen that, firstly, by inserting the docking block 22 in the docking assembly 2 into the docking frame 21, a plurality of shock absorbing assemblies 1 are assembled to realize end-to-end connection to form a shock absorbing base, and the docking block 22 is connected by the first long rod bolt 23 While fastening with the limit of the docking frame 21, the limit is strengthened by means of the fit of the V-shaped block and the V-shaped groove;

[0042] Secondly, after the assembly is completed according to actual needs, one end of the second pallet 32 in the carrier assembly 3 is inserted into the first slot or the second slot of the first pallet 31, and according to the corresponding installation position (that is, the docking frame of the installation position) 21 and the orientation of the docking block 22), after the first supporting plate 31 fits with the upper wall of the docking frame 21 and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com