Back pressure valve with flow and pressure control function

A technology of pressure control and back pressure valve, which is applied in the field of hydraulic power system, and can solve the problems of back pressure system air leakage, system failure, and the failure of the sealed steel ball to reset normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

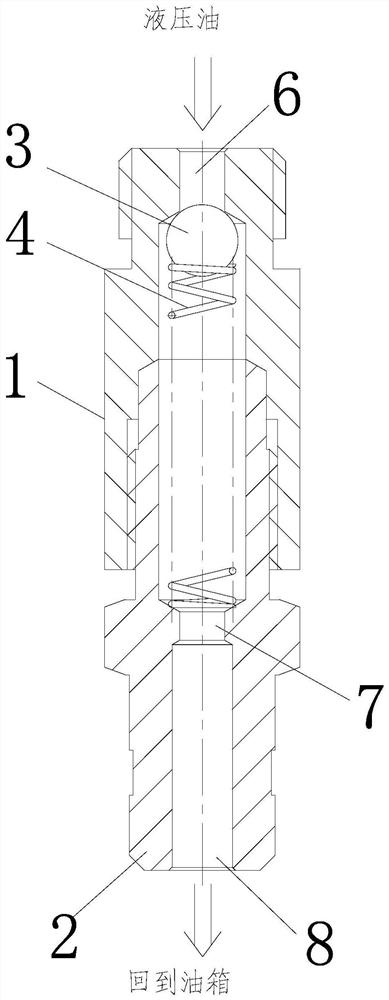

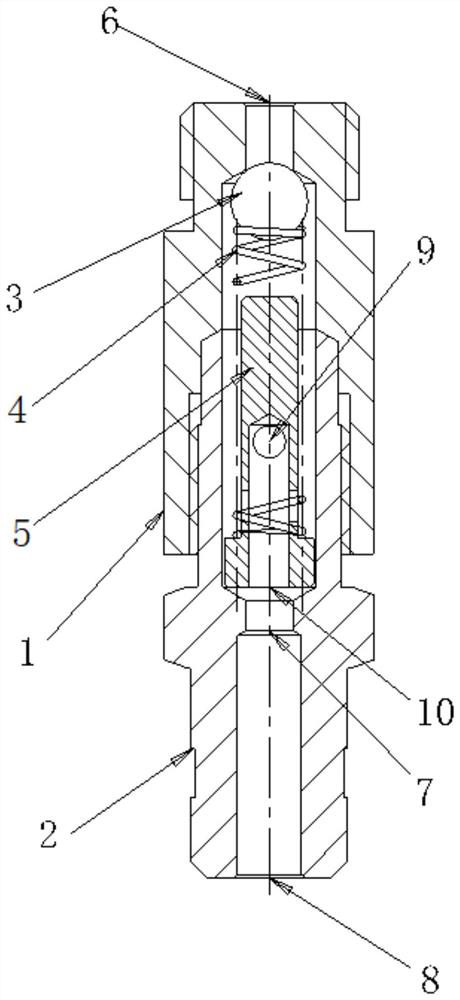

[0029] A back pressure valve with flow and pressure control functions, comprising a valve casing 1 and a pressure regulating seat 2 connected with the valve casing 1, the upper half of the valve casing 1 and the pressure regulating seat 2 are connected on the Together, and in order to ensure that oil does not leak from the gap between the two, a sealing ring is provided at the connection between the valve housing 1 and the pressure regulating seat 2,

[0030] The valve casing 1 is provided with an oil inlet hole 6, and the pressure regulating seat 2 is provided with an oil inlet hole 7 and an oil outlet hole 8, and an inner cavity is formed between the valve casing 1 and the pressure regulating seat 2. The inner cavity is located between the oil inlet hole 6 and the oil inlet hole 7,

[0031] Sealing steel balls 3, springs 4 and spring seats 5 are sequentially arranged in the inner cavity from top to bottom, one end of the spring 4 is nested outside the spring seat 5, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap