Method for repairing burnt transformer pile head

A repair method, transformer technology, applied in the direction of transformer/inductor parts, inductor/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc. Achieve the effect of high applicability, simple work, and reduced safety risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

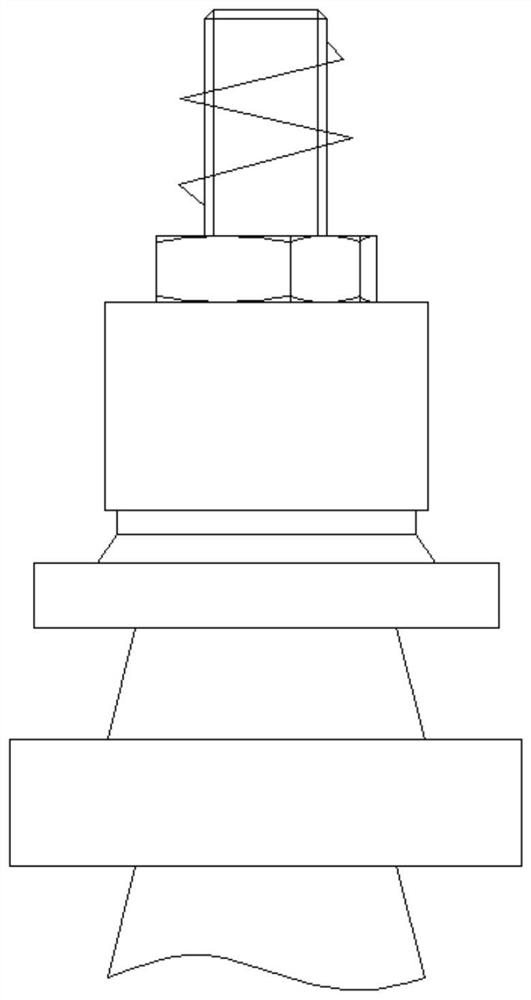

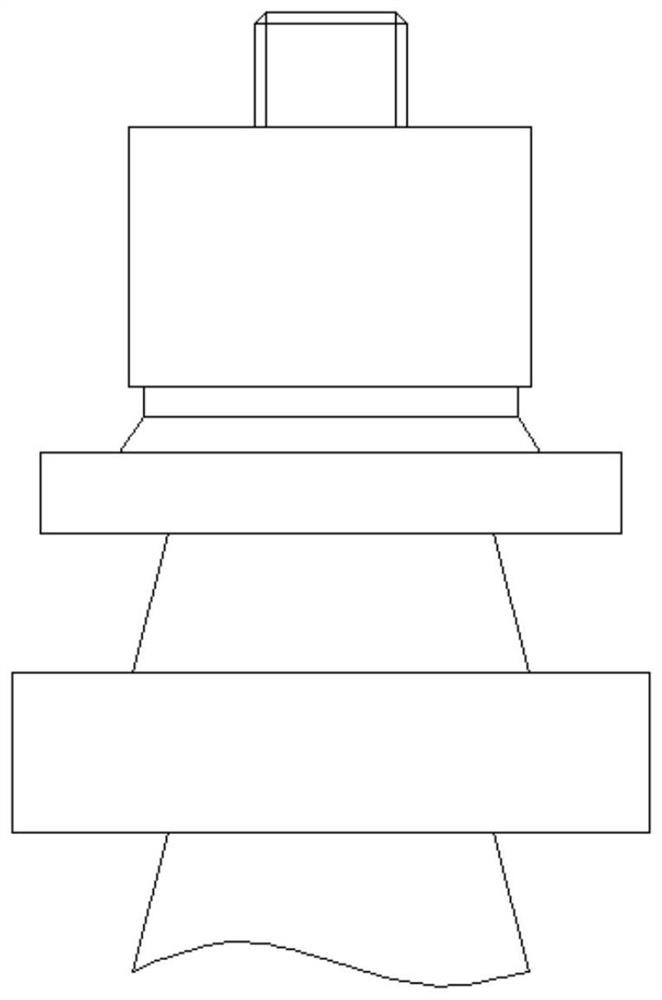

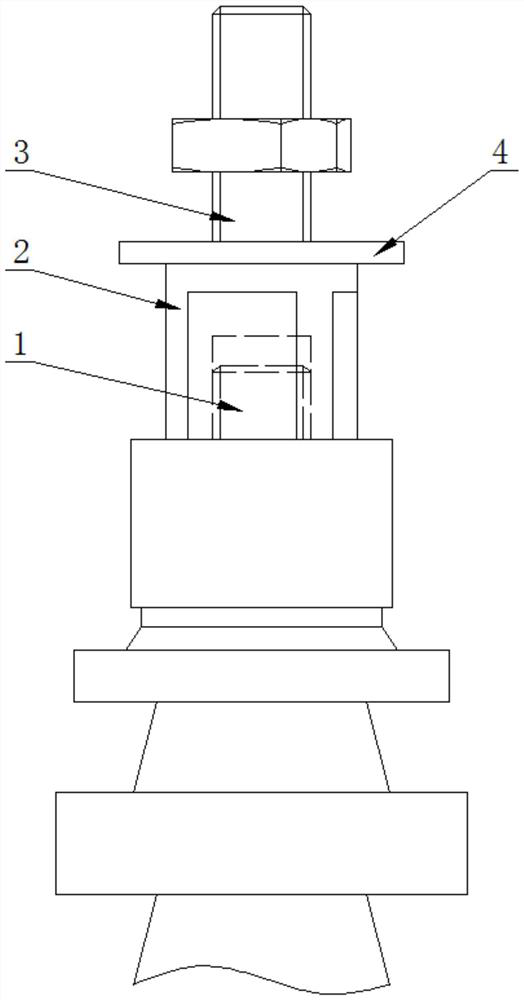

[0027] refer to figure 1 , the present embodiment provides a method for repairing a transformer pile head after burning out; a repairing method for a transformer pile head after burning out; comprising the following steps:

[0028] S1. Check the size parameters of the screw on the transformer burnout pile head 1;

[0029] S2. Process a butt nut 2 matching the size of the screw for use, and at the same time, a bolt section 3 is arranged on the other side of the butt nut;

[0030] S3. Remove the wire clamp at the burnt pile head position on the transformer after power failure;

[0031] S4. Use a sawing device to cut off the burnt section of the pile head 1, and keep a complete pile head screw during sawing;

[0032] S5. Install the butt nut 2 on the remaining pile head screw; then install the wire clip on the bolt section 3 of the butt nut to complete the repair of the transformer pile head.

[0033] As a spare butt nut 2, it is a step structure made of copper material; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com