Single independent compensation molding technology for molding of PCB gong board

A kind of gong plate and technology, which is applied in the field of independent compensation molding of each forming plate of PCB gong plate, can solve the problems of affecting the efficiency of forming gong plate, increase the cost of forming gong plate, waste production time, etc., and achieve uniform shape and dimensional accuracy of gong plate. Consistent, improve the efficiency of the gong board, and meet the requirements of precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

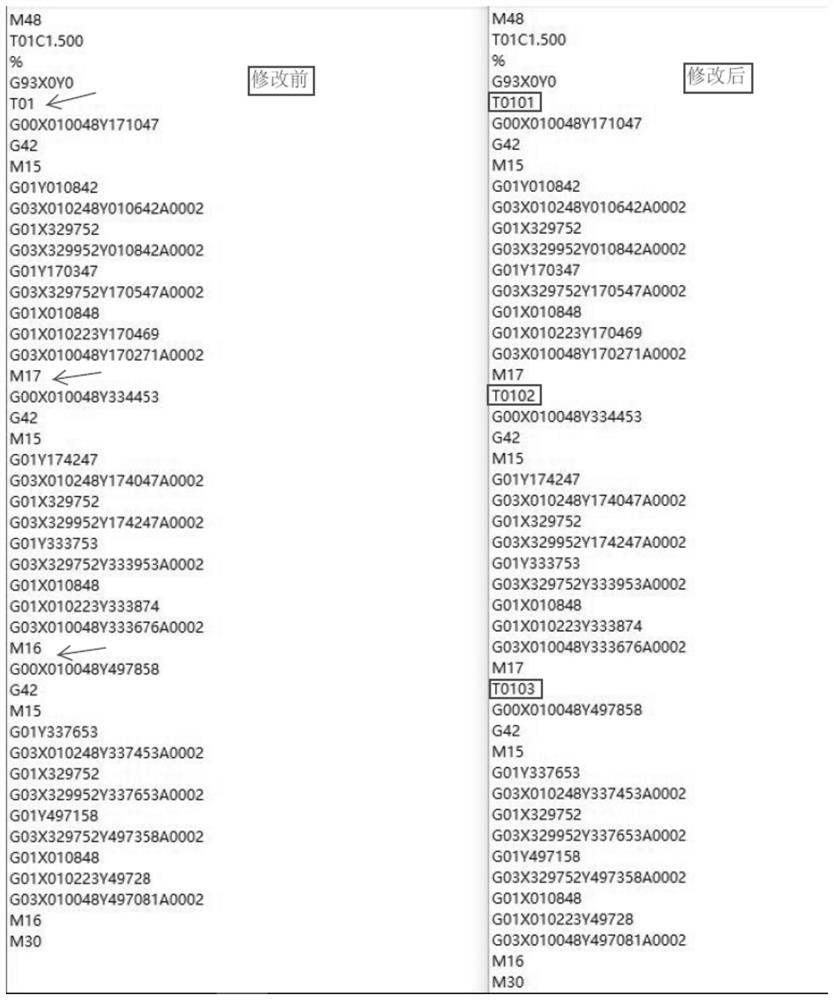

[0025] Combine figure 1 A PCB panel has a single independent compensation molding technology. Engineering designers use computer-assisted design CAM software. According to the shape of each product, the corresponding CNC panel processing procedure is designed, and the designs that are derived from the method identifiable. file format;

[0026] Use the count to open the board program file, manually increase the boat board instruction: increase the tool code and 01, 02, 03, 04 ... serial number, example: first tool after each tool's processing end command M16 or M17: first tool increase T0101, T0102, T0103 ...; second tool increases T0201, T0202, T0203 ..., and so on.

[0027] After the T digital serial number is completed, the M16 command is changed to M17. The M16 of the program ends does not change, and the modification is saved.

[0028] The 机 can identify the modified instructions, and a plurality of compensation values can occur by adding instructions to control each single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com