J-shaped seamed edge correction auger bit

A twist drill bit and edge technology, applied in twist drills, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of final requirements of parts, dimensional accuracy and position accuracy can not be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

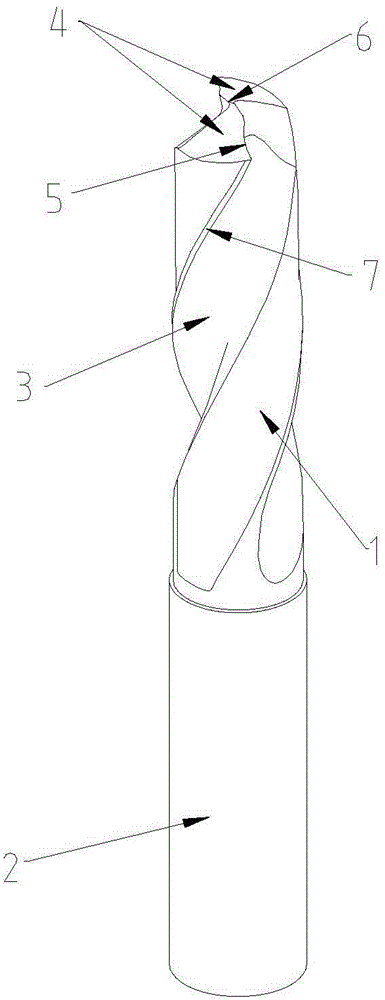

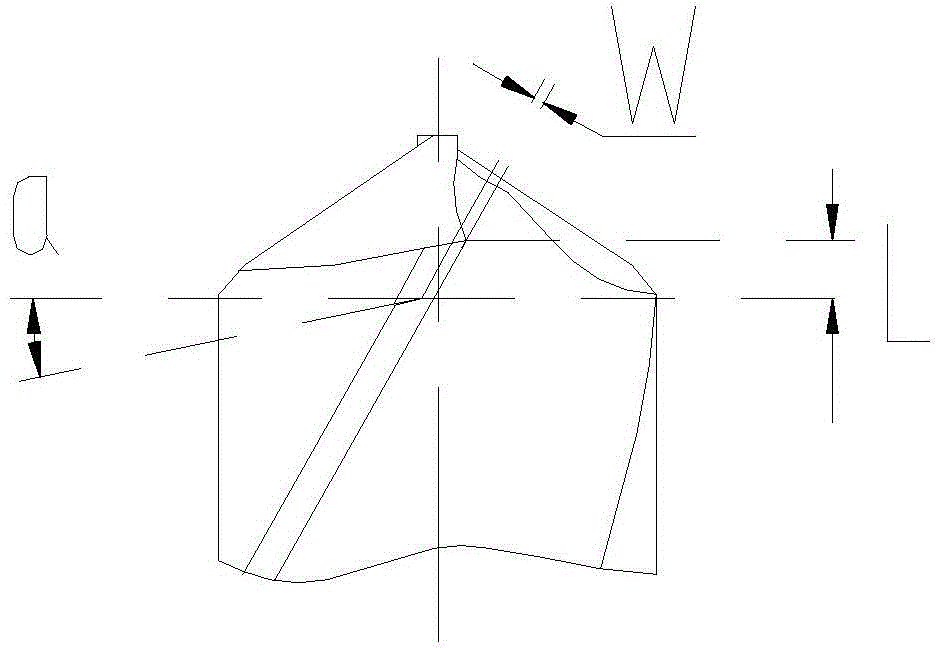

[0017] Such as figure 1 As shown, the J-shaped edge correction twist drill includes cutter body 1 and shank 2. The cutter body 1 and shank 2 are coaxial cylinders centered on the same central axis, and the shank 2 is a section with higher circular accuracy. The cylinder, when in use, clamps the shank 2 through the tool handle to transmit the power of the machine tool to make the tool rotate and have cutting ability. A spiral chip flute 3 is ground on the cutter body 1, and two flanks 4 are ground on the end face of the cutter body head, and the intersection line of the flank 4 and the chip flute 3 forms a main cutting edge 5 , the intersection line of the two flanks 4 forms a chisel edge 6, and at the position of the cutter body 1 close to the chip flute 3, the excess part of the cutter body is ground by the edge cleaning process, leaving only a spiral cylindrical surface, forming edge 7.

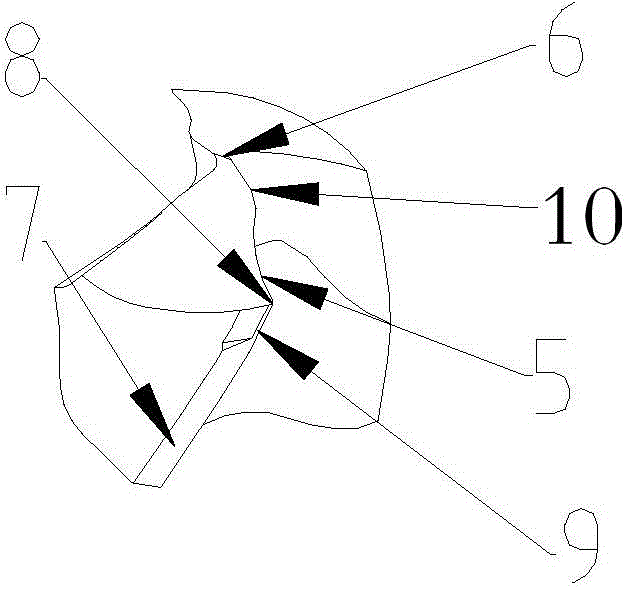

[0018] Such as figure 2 As shown, an inner edge 10 is ground between the main cutti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com