Anti-deformation supporting device for assembling and welding nozzle connecting pipe

A support device and anti-deformation technology, which is applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of inapplicability of anti-deformation devices, and achieve the effects of improving product quality, reliable anti-deformation, and preventing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

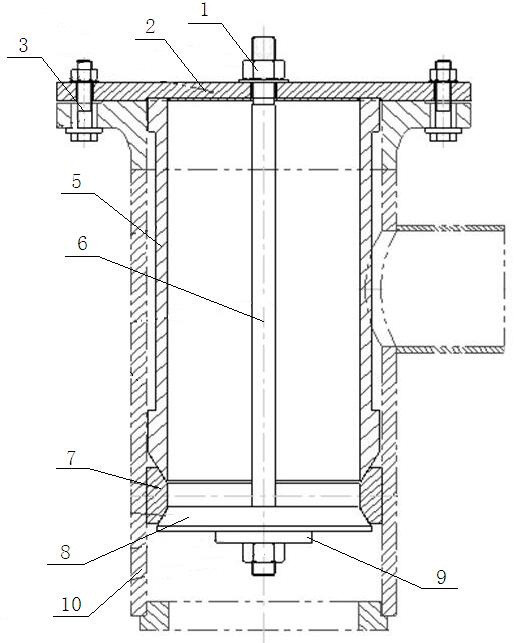

[0014] An anti-deformation support device for nozzle pipe fitting and welding, which consists of a gland 2, a pull rod 6, a positioning tube 5, an expansion piece 7 and a pull plate 8, the bottom of the pull rod is threadedly connected with a nut 1, and the bottom of the pull rod is threaded. The pull plate and the expansion sheet are sheathed in turn, the positioning tube is put on the tie rod, the gland is put on the tie rod and fixed with the connecting pipe 10 by the bolt 3 .

Embodiment 2

[0016] According to the anti-deformation support device for nozzle pipe assembly and welding described in Embodiment 1, the slope at the bottom of the positioning tube, the slope at the top of the pull plate and the slope of the expansion piece are attached.

Embodiment 3

[0018] According to the anti-deformation support device for welding nozzle nozzles described in Embodiment 1 or 2, the expansion sheet is composed of three circular arc sheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com