Mechanical arm for numerical control machine tool

A technology of CNC machine tools and robotic arms, applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

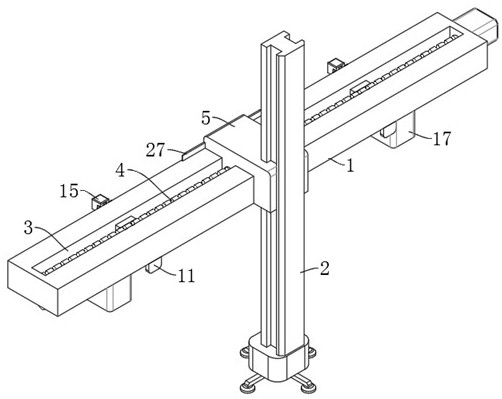

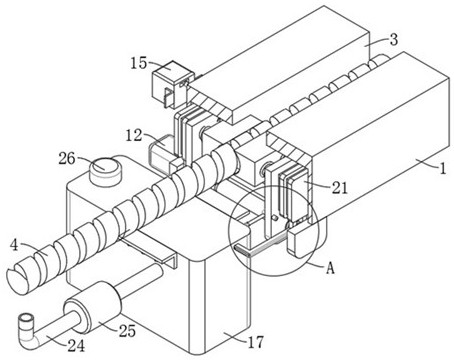

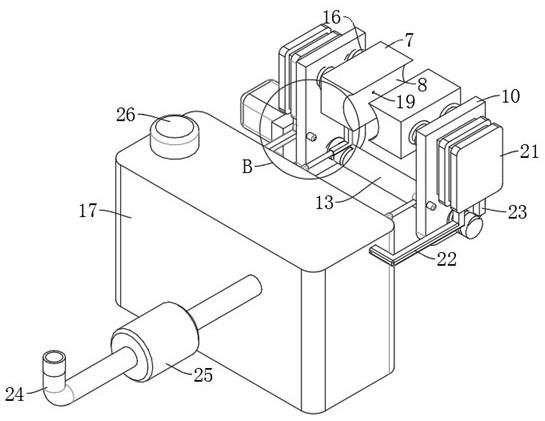

[0030] refer to Figure 1-6 , a mechanical arm for a numerically controlled machine tool, comprising a Y-axis slide rail 1 provided with a chute 3 and a screw mandrel 4, and also comprising: a sliding seat 5 threaded on the screw mandrel 4 and slidably connected in the chute 3, Wherein, the sliding seat 5 is slidably connected with a Z-axis swing arm 2 with a handle at the lower end; the clamping part is arranged on the left and right inner walls of the chute 3 and is located in the middle of the Y-axis slide rail 1, wherein the clamping part includes Sliding holes 6 are provided on the left and right inner walls of the chute 3, and sliders 7 are slidably connected in the two sliding holes 6, and the opposite side walls of the two sliders 7 are provided with arc-shaped grooves 8 that are offset against the outer wall of the screw rod 4 , the lower end of the Y-axis slide rail 1 is provided with an opening and closing mechanism connected with the two sliders 7; the oil storage ...

Embodiment 2

[0034] refer to Figure 2-6 , which is basically the same as that of Embodiment 1, furthermore: the opening and closing mechanism includes two supports 11 fixedly installed at the lower end of the Y-axis slide rail 1, and a double-ended threaded rod 13 is installed in rotation between the two supports 11, wherein A drive motor 12 is fixedly installed on the outer wall of a support 11, the output end of the drive motor 12 is fixedly connected with one end of a double-ended threaded rod 13, and both ends of the double-ended threaded rod 13 are threadedly connected with a slide plate 10 and a Y-axis slide rail Both sides of the lower end of 1 are provided with sliding chambers 9 connected to the sliding holes 6. Two sliding plates 10 are respectively slidably connected in the two sliding chambers 9 and connected with the two sliding blocks 7 respectively. The Y-axis slide rail 1 is provided with The automatic trigger mechanism connected with the drive motor 12, when the sliding s...

Embodiment 3

[0037] refer to figure 1 , figure 2 as well as Figure 5 , which is basically the same as in Embodiment 1, furthermore: the automatic trigger mechanism includes a reverse button 15 fixedly installed on the Y-axis slide rail 1, the reverse button 15 is aligned with the position of the slider 7, and the reverse button 15 is aligned with the position of the slider 7 The driving motor 12 is electrically connected, and both sides of the sliding seat 5 are fixedly connected with a trigger lever 27 cooperating with the reverse button 15, and both sides of the slide plate 10 are fixedly installed with a limit switch 14 electrically connected with the driving motor 12, When the sliding seat 5 is moving, when the reverse button 15 is touched by the trigger lever 27, the driving motor 12 will drive the double-ended threaded rod 13 to rotate in the opposite direction. When the sliding seat 5 passes over the slider 7, the sliding seat 5 will simultaneously Separated from the reverse butto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com