Injection molding mold and injection molding method using same

A technology of injection molding and moulds, which is applied in the field of injection molding moulds, can solve the problems of high labor intensity, labor cost and time cost, and low work efficiency of operators, so as to reduce production labor intensity, improve production efficiency, and improve yield rate and appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

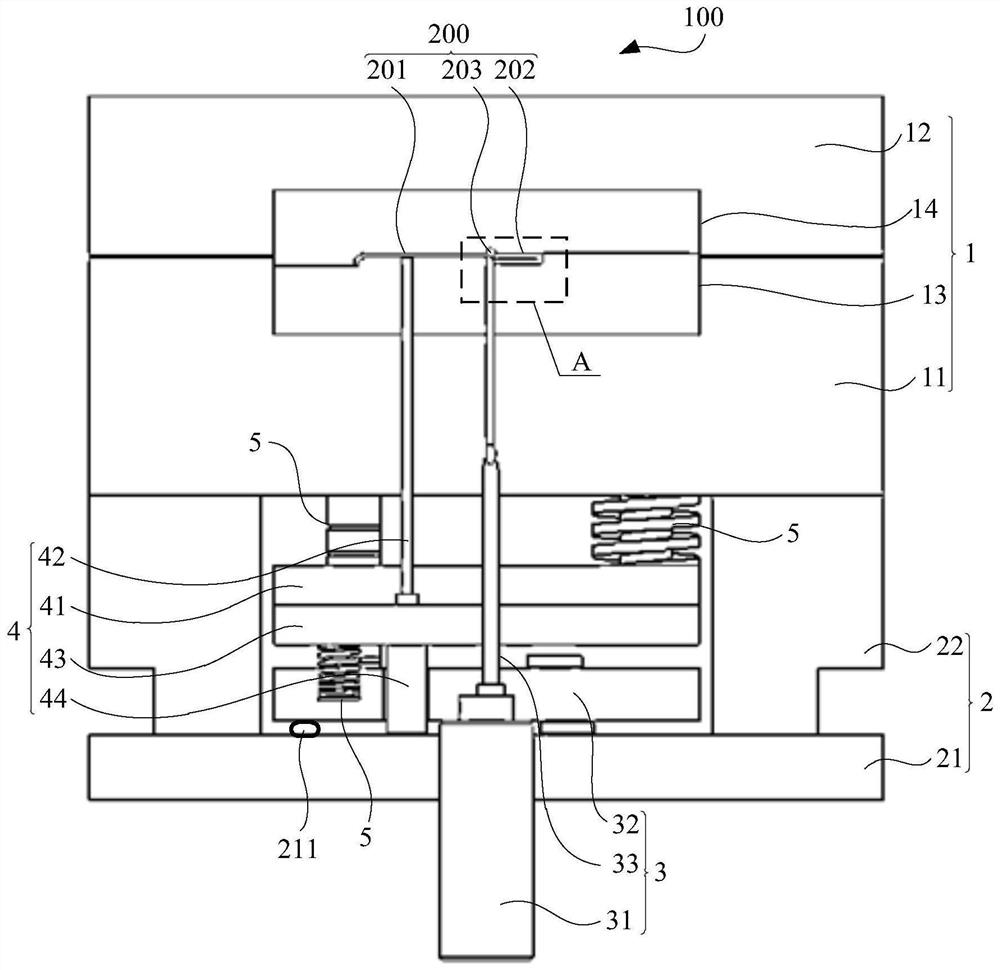

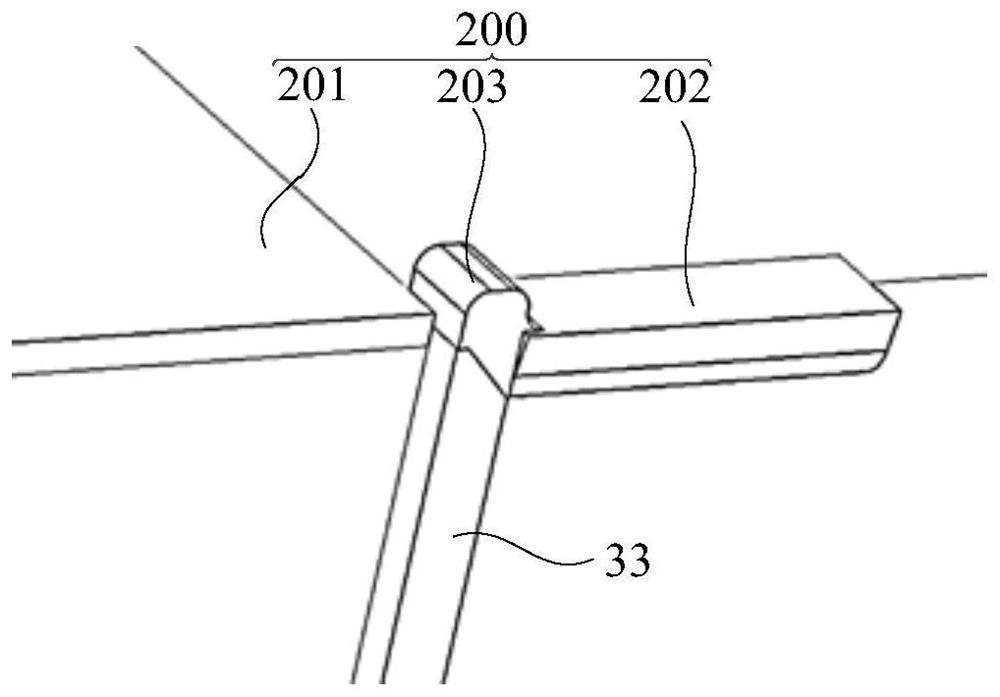

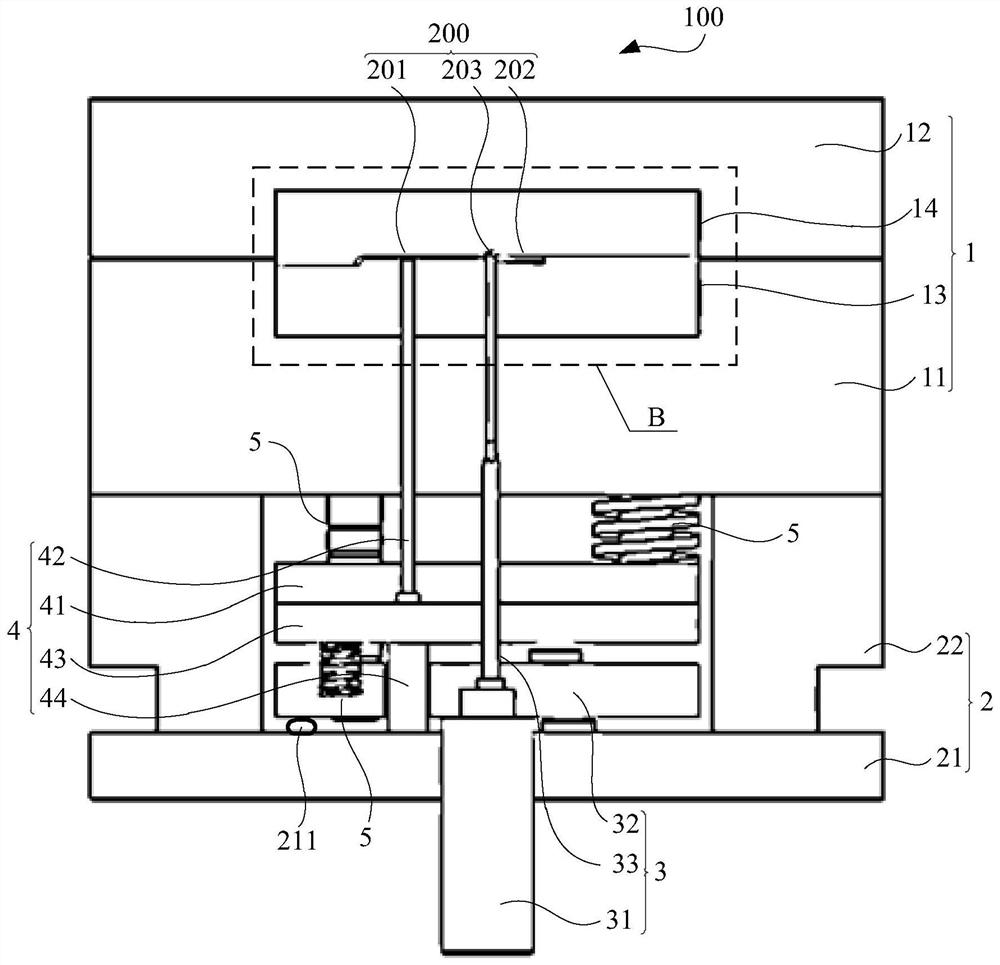

[0045] figure 1 Schematic diagram of the structure of the injection molding mold provided by Embodiment 1 of the present invention; figure 2 for figure 1 The three-dimensional schematic diagram of A; image 3 for figure 1 A schematic diagram of the state of the injection molding mold in ; Figure 4 for image 3 Partial enlarged view of B in middle; Figure 5 for figure 1 Another state diagram of the injection molding mold in ; Image 6 for Figure 5 The three-dimensional schematic diagram at C.

[0046] refer to figure 1 and figure 2As shown, the injection molding mold 100 provided in this embodiment includes a mold base component 1 , a support component 2 , a first jacking component 3 and a second jacking component 4 . Wherein, the mold base assembly 1 is used to form the injection molded part 200, and the support assembly 2 is used to support the mold base assembly 1, for example, the bottom end of the support assembly 2 is supported on the ground or on a mounti...

Embodiment 2

[0082] Figure 7 It is a schematic flow chart of the injection molding method provided by the second embodiment of the invention. refer to Figure 7 As shown, this embodiment provides an injection molding method, which is applied to the injection molding mold 100 of Embodiment 1 for injection molding plastic parts.

[0083] Specifically, the method includes the following steps:

[0084] S100. Inject molten plastic into the mold base assembly to form a molten injection molded part; wherein, the injection molded part includes an injection molded body and a gate connected to the injection molded body, and the connection between the gate and the injection molded body is cut off department.

[0085] combine figure 1 As shown, first, the molten plastic is injected into the mold base assembly 1 through the injection machine, specifically, the molten plastic is injected into the injection cavity formed between the fixed plate 13 and the movable plate 14 in the mold base assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com