Automatic landing leg leveling system, control method and wheeled crane

A wheeled crane and automatic leveling technology, which is applied in the direction of cranes, fluid pressure actuated system components, mechanical equipment, etc., can solve the problems that the manual leveling of outriggers is difficult to ensure the accuracy, etc., so as to reduce the difficulty of operation and labor intensity, and ensure The effect of leveling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

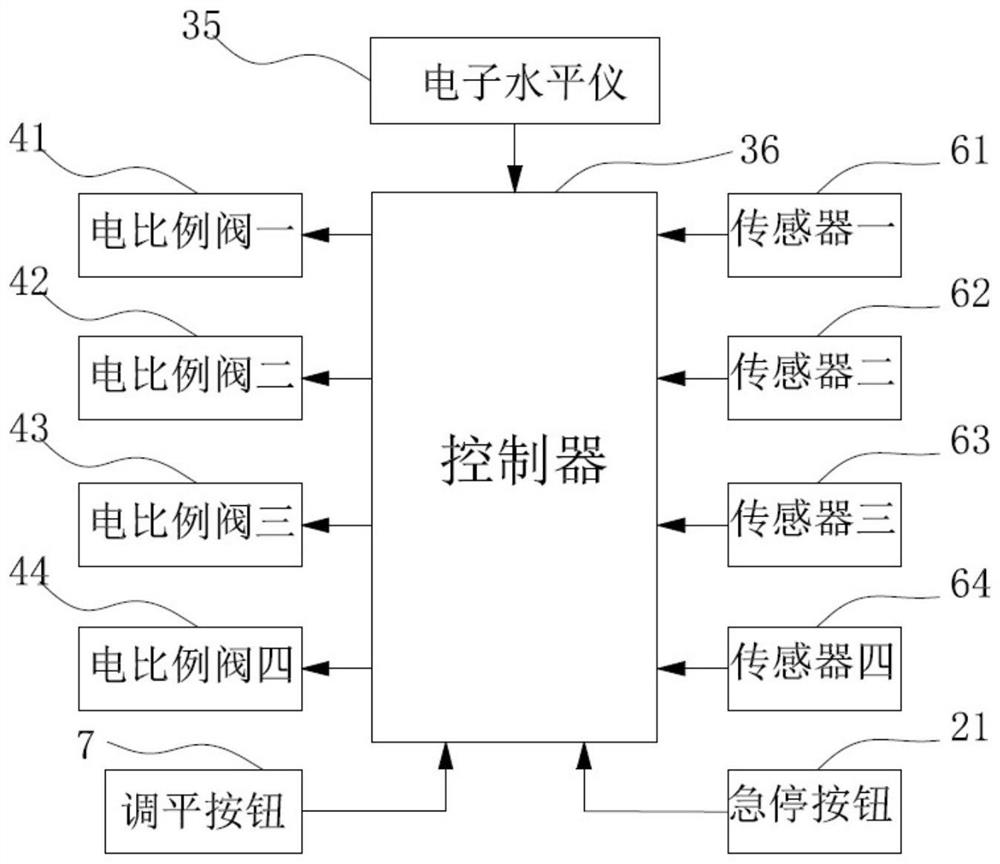

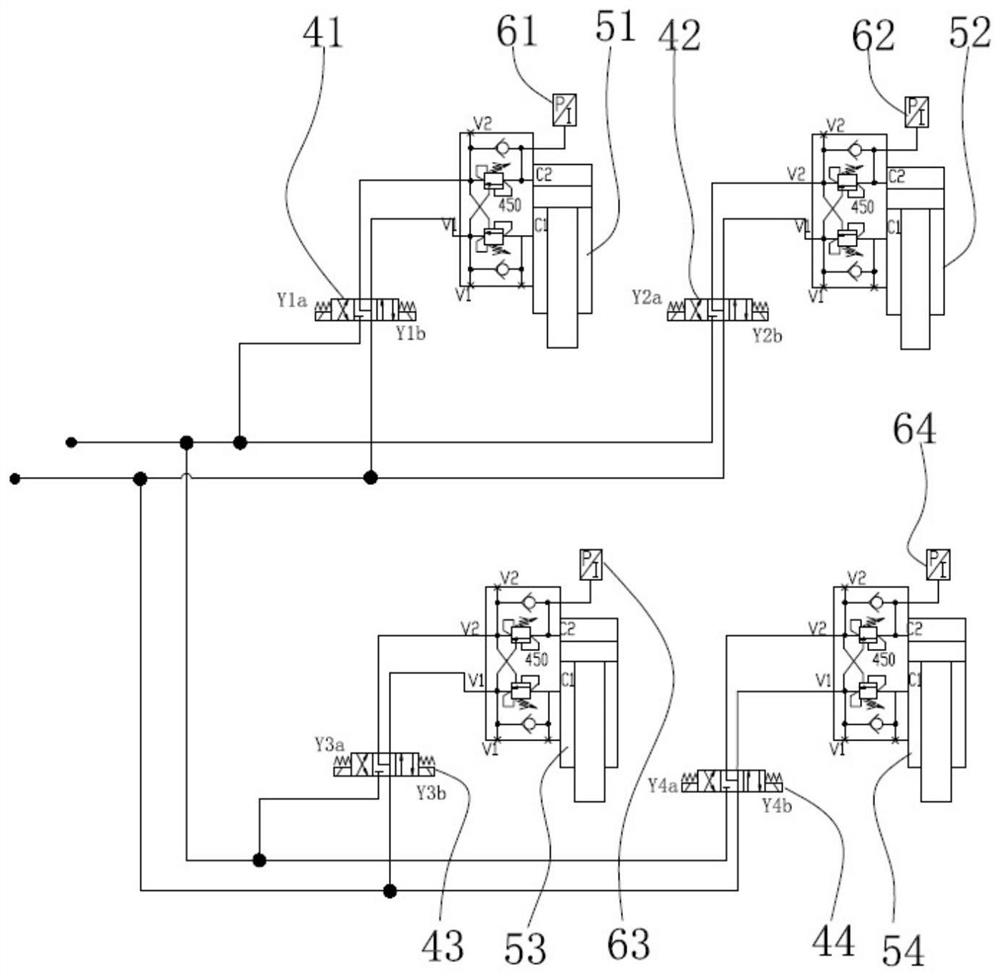

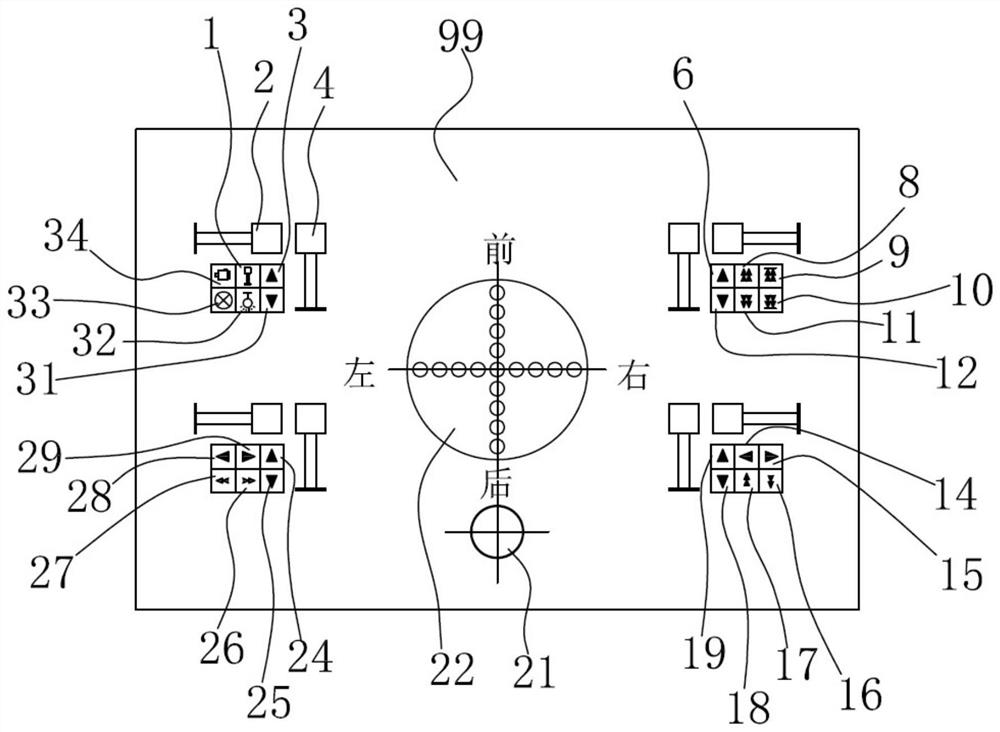

[0028] The specific implementation will be described below in conjunction with the accompanying drawings.

[0029] The wheeled crane consists of a chassis on which a turntable is mounted. The chassis consists of a frame and outriggers mounted on either side of the frame. Each side of the vehicle frame is respectively equipped with two supporting legs, and the four supporting legs are respectively a right front supporting leg, a right rear supporting leg, a left front supporting leg and a left rear supporting leg. Each outrigger is equipped with a horizontal oil cylinder and a vertical oil cylinder, which are used to extend the outrigger horizontally and vertically to lift the vehicle frame and make the wheels suspend. When the crane is hoisting, the outriggers should be laid first. When the horizontal oil cylinder is in place, the vertical oil cylinder should be extended to keep the chassis tires off the ground without force, and at the same time keep the frame in a horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com