Preparation method of alkali metal and alkaline earth metal sulfide

An alkaline earth metal and alkali metal technology, applied in the direction of alkali metal sulfide/polysulfide, magnesium/calcium/strontium/barium sulfide/polysulfide, etc. , high equipment requirements, to achieve the effect of high yield, short reaction time and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

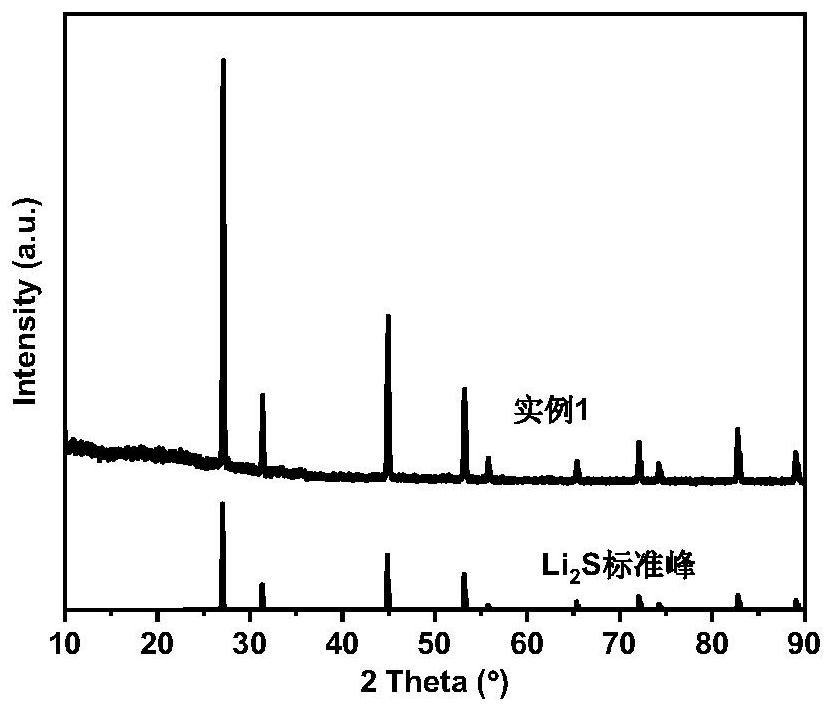

[0024] Lithium hydroxide and thiourea were mixed in a molar ratio of 1:2.6, ground in a mortar for 20 minutes, then transferred to a crucible, placed in a tube furnace, and kept at 400°C for 3 hours under argon to obtain lithium sulfide, X The ray diffraction pattern see figure 1 ;

Embodiment 2

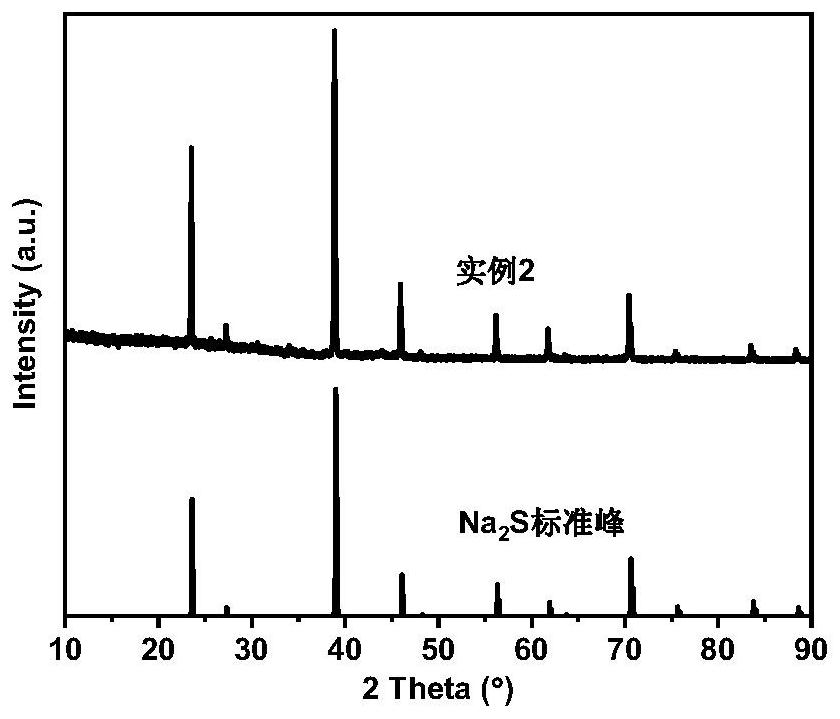

[0026] Sodium chloride and thiourea were mixed according to the molar ratio of 1:3.2, ground in a mortar for 20 minutes, then transferred to a crucible, placed in a tube furnace, and kept at 400°C for 2.5 hours under argon to obtain sodium sulfide. X-ray diffraction pattern see figure 2 ;

Embodiment 3

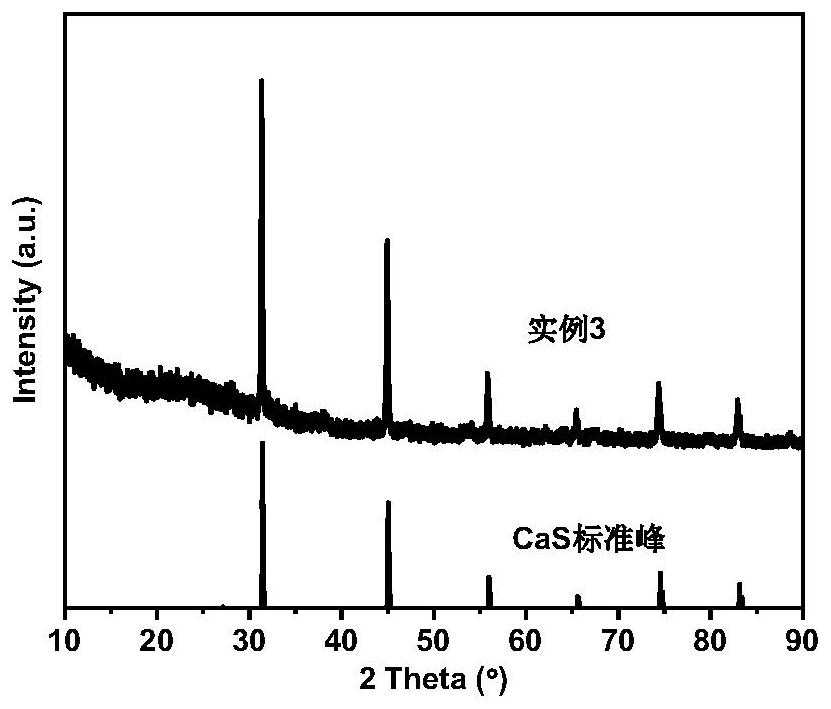

[0028] Mix calcium hydroxide and thiourea at a molar ratio of 1:3, grind in a mortar for 30 minutes, transfer to a crucible, place in a tube furnace, and keep warm at 550°C for 12 hours under argon to obtain calcium sulfide, X The ray diffraction pattern see image 3 ;

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap