Wood structure connecting joint long in service life and convenient to replace

A technology for connecting nodes and wooden structures, which is applied in the direction of building components, building structures, building insulation materials, etc., can solve the problems of inconvenient replacement, single scope of application, inconvenient adjustment, etc., and achieve the effect of easy replacement, ensuring safety and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

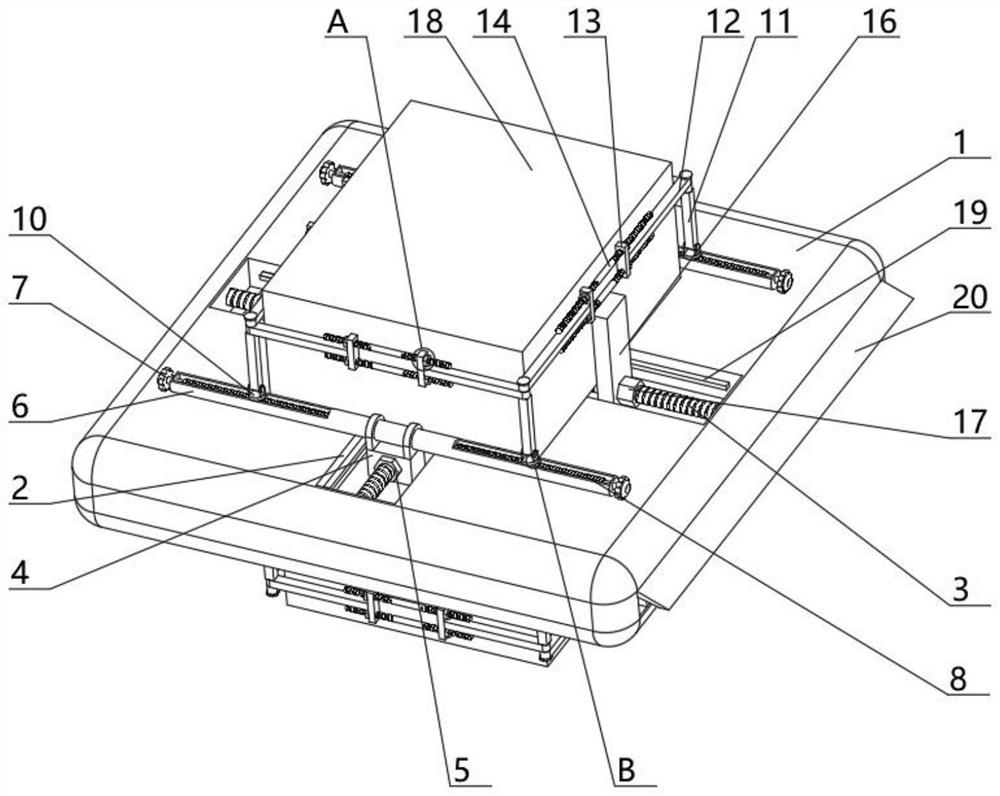

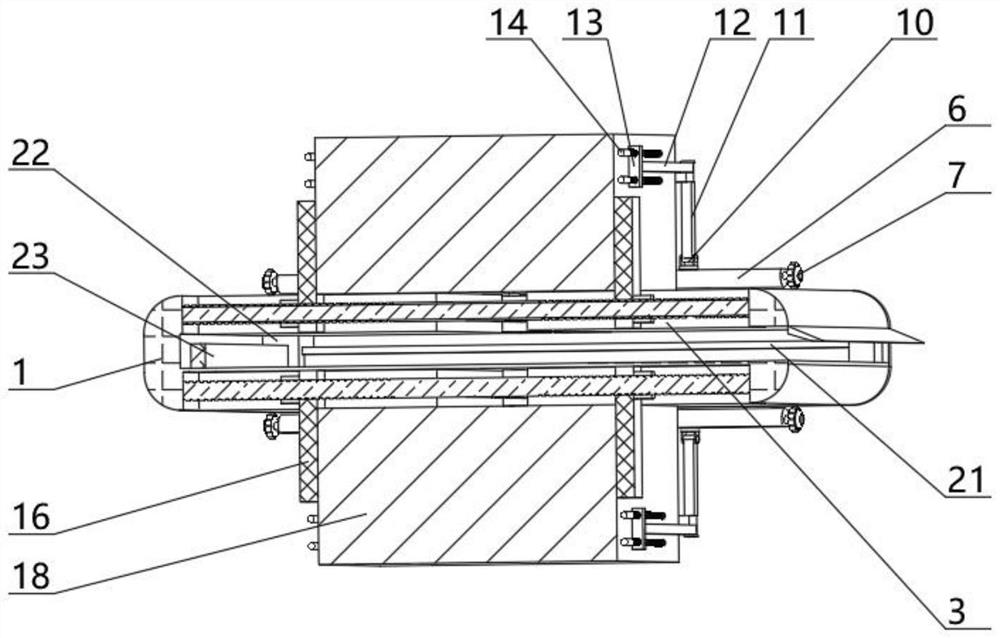

[0029] see Figure 1-4 , a high-life and easy-to-replace wooden structure connection node, including a connection platform 1, the outer wall of the connection platform 1 is symmetrically provided with a cross groove 2, and the middle part of the inner wall of the cross groove 2 is fixedly installed with a cross thread rod 3, and the two cross thread rods 3 The outer wall of the side is slidingly connected with an adjustment block 4, the outer walls of both sides of the cross threaded rod 3 are threaded with a first nut 5, the first nut 5 fits with the adjustment block 4, and the inner wall of the adjustment block 4 is rotated and installed with an installation hollow shaft 6, The outer wall of the hollow shaft 6 is installed with a rotating ring 7 symmetrically plugged in, the input end of the rotating ring 7 is fixedly equipped with a lead screw 8 , and the outer wall of the lead screw 8 is threadedly connected with a nut block 9 .

[0030] In this embodiment, by setting the ...

Embodiment 2

[0032] see Figure 1-4 , the present embodiment is further optimized on the basis of Embodiment 1, specifically, the upper surface of the nut block 9 is rotatably mounted with a mounting block 10, the inner wall of the mounting block 10 is rotatably mounted with a mounting rod 11, and the cross threaded rod 3 Adopt the setting of half thread and half optical axis.

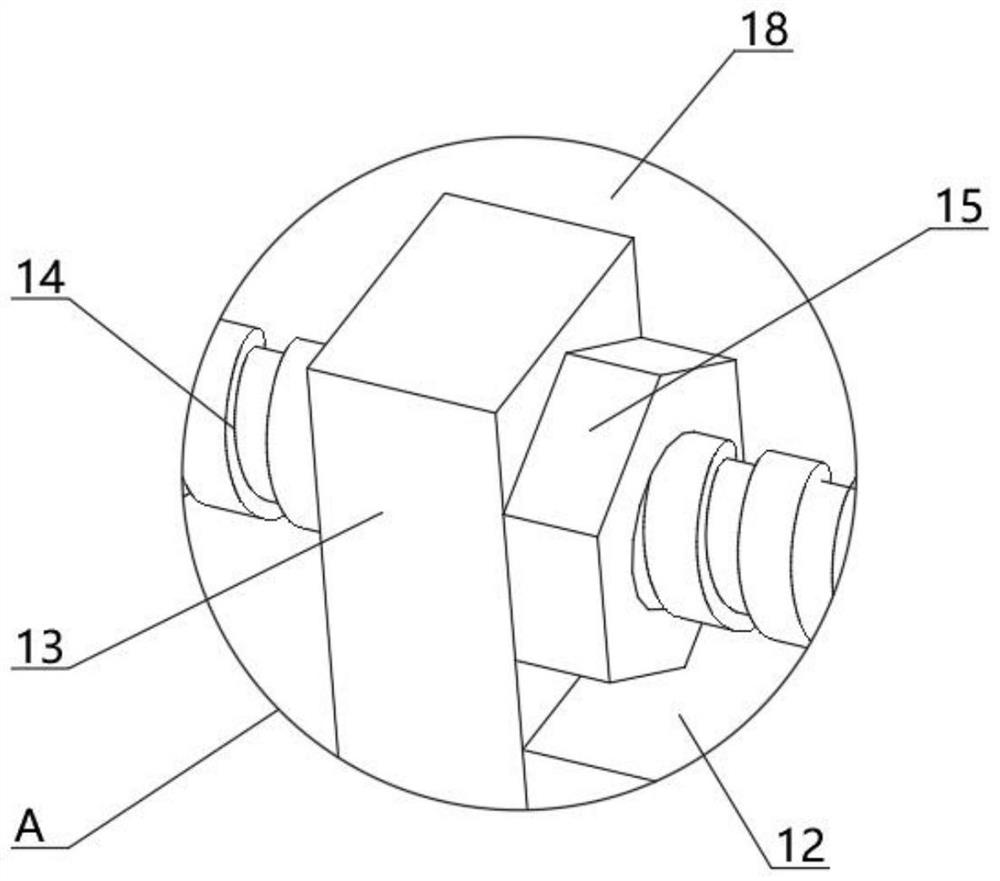

[0033] Specifically, the top of the outer wall of the mounting rod 11 is symmetrically rotated with a connecting rod 12, and the end of the connecting rod 12 away from the mounting rod 11 is fixedly installed with a connecting plate 13, and the outer wall of the connecting rod 12 is provided with a rubber layer. 18, on the other hand, can protect the place where connecting rod 12 contacts with block 18 from being damaged.

[0034] Specifically, the inner wall of the connecting plate 13 is symmetrically slidably mounted with a double-ended threaded rod 14, and the outer wall of the double-ended threaded rod 14 is s...

Embodiment 3

[0038] see Figure 1-4 , the present embodiment is optimized as follows on the basis of Example 1 or Example 2, specifically, the end of the connecting plate 13 far away from the third nut 17 is connected with a wooden block 18, and the inner wall of the cross groove 2 is symmetrically provided with drying The device 19 and the drying device 19 can ensure that the connecting points of the wooden blocks 18 are in a dry state, so as to avoid corrosion of the wooden blocks 18 caused by moisture.

[0039] Specifically, a rain shield 20 is fixedly installed on the outer wall of the connecting platform 1 , and guide rails 21 are symmetrically fixedly installed on the inner wall of the connecting platform 1 .

[0040] Specifically, an electric slider 22 is slidably installed on the outer wall of the guide rail 21, and a scraper 23 is fixedly installed on the outer wall of the electric slider 22. The scraper 23 is made of rubber material, which can avoid scratching the connection tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com