Fabricated energy-saving building wall and mounting method

A building wall and assembly technology, which is applied in the direction of buildings, building components, building materials, etc., to achieve excellent environmental protection and energy saving effects, excellent earthquake and wind resistance effects, and stable and firm structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

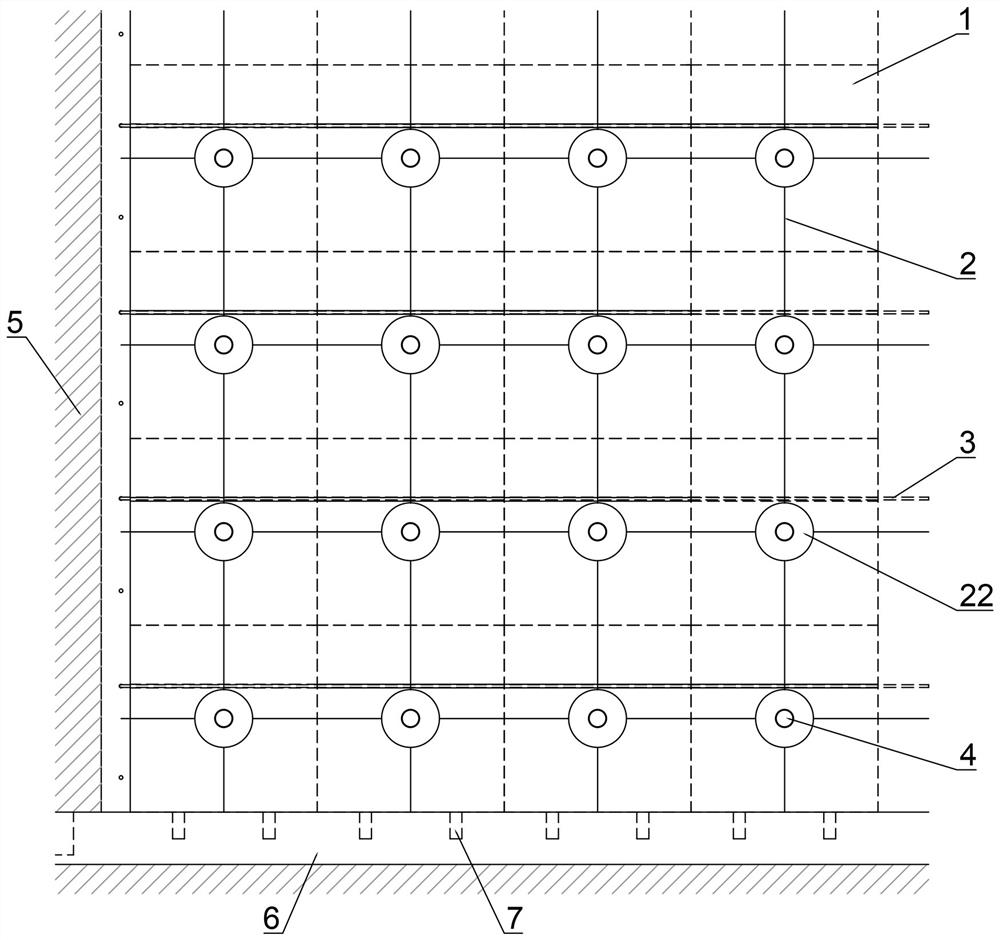

[0054] A prefabricated energy-saving building wall, such as figure 1 As shown, it includes the main wall and the protective wall, and the protective wall is covered on the two sides of the main wall, wherein the main wall includes the main frame and the wall unit block 1 spliced in the main frame, and the wall The body unit blocks 1 are spliced in series to form an integral connection mechanism.

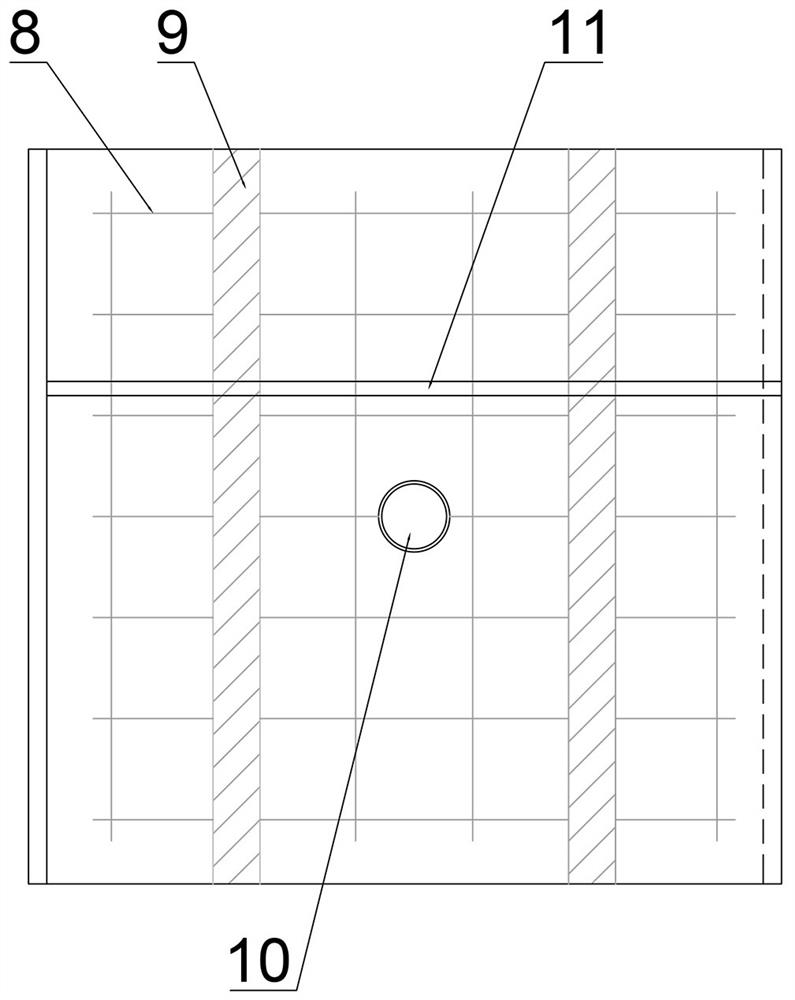

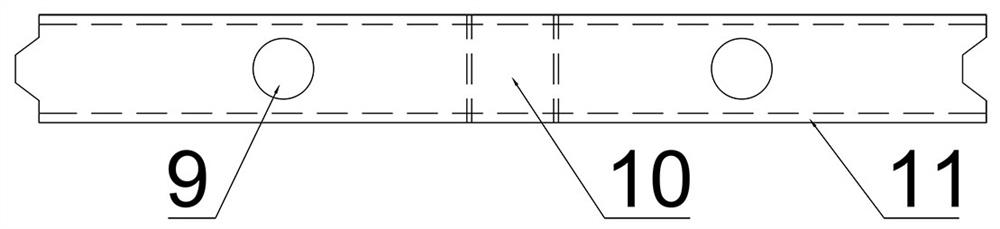

[0055] exist figure 2 Among them, the wall unit block 1 is a prefabricated square prefabricated part of concrete and steel skeleton 8, the two sides of the wall unit block 1 are planes, and the left and right sides of the wall unit block 1 are coincident protrusions and grooves The splicing of the main wall is realized through the fitting of adjacent wall unit blocks 1. The reinforcement skeleton 8 includes two vertically arranged parallel pipes 9, and the vertically adjacent wall unit blocks 1 inside the pipes 9 communicate with each other, and the through pipe 9 is parallel ...

Embodiment 2

[0067] A prefabricated energy-saving building wall, including a main wall and a protective wall, the protective wall is covered on two sides of the main wall, wherein the main wall includes a main frame and a wall unit spliced in the main frame block 1, and the connecting mechanism for splicing the wall unit blocks 1 in series to form a whole.

[0068] The wall unit block 1 is a prefabricated square prefabricated part of concrete and steel skeleton 8. The two sides of the wall unit block 1 are planes, and the left and right sides of the wall unit block 1 are coincident protrusions and grooves. The splicing of the main wall is achieved by the fitting of adjacent wall unit blocks 1. The steel bar skeleton 8 includes two vertically arranged parallel pipes 9, and the vertically adjacent wall unit blocks 1 have two pipes 9 that are connected to each other. Connected, the pipes 9 are parallel to the two sides of the wall unit block 1, at least one positioning pipe 10 is arranged b...

Embodiment 3

[0071] A prefabricated energy-saving building wall, including a main wall and a protective wall, the protective wall is covered on two sides of the main wall, wherein the main wall includes a main frame and a wall unit spliced in the main frame block 1, and the connecting mechanism for splicing the wall unit blocks 1 in series to form a whole. The protective wall is integrally formed in the shape of a whole plate, with through holes evenly opened on it, and a wall fixture 4 is arranged at the through hole, and the wall fixture 4 passes through the through hole on the protective wall and is fixed to the on both sides of the main wall.

[0072] The wall unit block 1 is a prefabricated square prefabricated part of concrete and steel skeleton 8. The two sides of the wall unit block 1 are planes, and the left and right sides of the wall unit block 1 are coincident protrusions and grooves. The splicing of the main wall is achieved by the fitting of adjacent wall unit blocks 1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com